Conclusion: Choosing the Best Ink for Your Screen Printing Needs

In conclusion, determining the best ink for screen printing depends on various factors, including your specific project requirements, production volume, and desired outcome. While plastisol ink is often considered the industry standard and the best ink for screen printing in many situations, water-based, non-PVC plastisol, discharge, and specialty inks all have their place in a screen printer’s toolkit.

Consider your fabric type, design complexity, desired finish, and environmental concerns when choosing the best ink for screen printing. Remember that what’s considered the best ink for screen printing can vary depending on your specific needs and priorities.

Ultimately, the best ink for screen printing is the one that helps you achieve your desired results consistently and efficiently. By understanding the properties and applications of different screen printing inks, you can make an informed decision and produce high-quality prints that meet your clients’ expectations. Whether you’re looking for the best ink for silk screen printing, the best water based ink for screen printing, or the best plastisol ink for screen printing, there’s an option out there that will suit your needs perfectly.

What is the Best Ink for Screen Printing?

Introduction to Screen Printing Inks

Screen printing is a versatile technique used across various industries, from fashion to advertising. The key to achieving high-quality prints lies in choosing the best ink for screen printing. Whether you’re working with fabric, paper, or other materials, selecting the right ink can make all the difference in the final product’s appearance and durability.

Types of Screen Printing Inks

Plastisol Ink: The Industry Standard

When it comes to the best ink for screen printing, plastisol ink often tops the list. This versatile ink is widely used in the textile industry due to its durability and vibrant color output. Plastisol ink is considered by many to be the best ink for silk screen printing, especially on dark fabrics.

Water-Based Ink: The Eco-Friendly Alternative

For those seeking an environmentally friendly option, water-based ink might be the best ink for screen printing. It’s often regarded as the best water based ink for screen printing due to its soft feel and eco-friendly properties.

Non-PVC Plastisol Ink: A Safer Option

Non-PVC plastisol ink is gaining popularity as one of the best inks for screen printing. It offers similar benefits to traditional plastisol but without the environmental concerns associated with PVC.

Discharge Ink: Creating Vintage Looks

Discharge ink is another contender for the best ink for screen printing, especially when aiming for a soft, vintage appearance on dark fabrics.

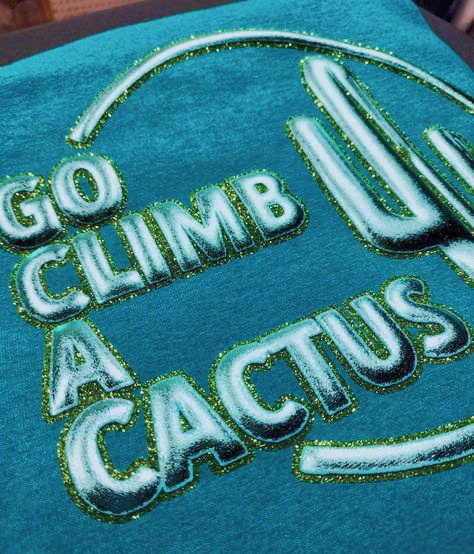

Specialty Inks: Adding Unique Effects

For special projects, various specialty inks like metallic, glitter, or puff inks might be considered the best ink for screen printing to achieve unique effects.

Factors to Consider When Choosing the Best Ink for Screen Printing

Fabric Type and Color

The type and color of the fabric play a crucial role in determining the best ink for screen printing. Dark fabrics often require more opaque inks, while lighter fabrics can work well with a variety of ink types.

Design Complexity

The intricacy of your design can influence which might be the best ink for screen printing your project. Some inks are better suited for detailed work, while others excel in covering large areas.

Durability Requirements

Consider how long you need the print to last. The best ink for screen printing durable designs might differ from the best ink for temporary or fashion-forward pieces.

Production Volume

When deciding on the best ink for screen printing, consider your production needs. Some inks are better suited for large-scale production, while others might be ideal for smaller runs.

Plastisol Ink: A Closer Look

Benefits of Using Plastisol Ink

Plastisol ink is often considered the best plastisol ink for screen printing due to its numerous advantages:

- Excellent opacity

- Vibrant colors

- Durability

- Versatility across fabric types

Drawbacks of Plastisol Ink

While plastisol is generally regarded as the best ink for screen printing, it does have some limitations:

- Can feel heavy on large print areas

- Requires heat curing

- Not ideal for printing over seams or folds

Water-Based Ink: The Eco-Friendly Choice

Advantages of Water-Based Ink

For those prioritizing environmental concerns, water-based ink might be the best ink for screen printing:

- Environmentally friendly

- Soft, breathable finish

- Excellent for light-colored fabrics

Challenges of Water-Based Ink

Despite its benefits, water-based ink presents some challenges that may affect its status as the best ink for screen printing:

- Quick-drying nature can be difficult to work with

- Requires more maintenance during printing

- Less opaque on dark fabrics

Non-PVC Plastisol Ink: A Safer Alternative

Benefits of Non-PVC Plastisol Ink

Non-PVC plastisol ink is becoming a popular choice for those seeking the best ink for screen printing:

- Similar properties to traditional plastisol

- Environmentally safer

- Complies with stricter regulations

Considerations for Non-PVC Plastisol Ink

When considering non-PVC plastisol as the best ink for screen printing, keep in mind:

- May require different curing temperatures

- Potentially higher cost than traditional plastisol

- Limited color options compared to standard plastisol

Specialty Inks: Expanding Your Options

Discharge Ink: Creating Unique Effects

Discharge ink offers a distinctive look that some consider the best ink for screen printing vintage or distressed designs:

- Produces soft, vintage-look prints

- Works well on dark fabrics

- Creates interesting tone-on-tone effects

Metallic and Glitter Inks: Adding Sparkle

For eye-catching designs, metallic or glitter inks might be the best ink for screen printing:

- Creates unique, shimmering effects

- Adds visual interest to designs

- Durable and long-lasting

Best Practices for Achieving Optimal Results

Proper Ink Selection

Choosing the best ink for screen printing is crucial for achieving high-quality results. Consider the fabric, design, and desired outcome when making your selection.

Screen Preparation and Technique

Even with the best ink for screen printing, proper technique is essential. Ensure your screens are well-prepared and your printing technique is refined for the best results.

Curing and Post-Print Care

Proper curing is crucial, especially when using plastisol ink. Follow manufacturer guidelines for the best ink for screen printing results that last.

Environmental Considerations in Choosing Screen Printing Inks

Eco-Friendly Options

When considering the best ink for screen printing, don’t overlook environmental impact. Water-based and non-PVC plastisol inks are often more eco-friendly choices.

Sustainability in Screen Printing

As the industry evolves, sustainable practices are becoming more important. Consider how your choice of the best ink for screen printing affects your overall environmental footprint.

Cost Considerations: Balancing Quality and Budget

Ink Costs and Value

While determining the best ink for screen printing, consider both the upfront cost and the value provided by each type of ink.

Long-Term Cost Efficiency

Sometimes, investing in a higher-quality ink can be more cost-effective in the long run, even if it’s not the cheapest option upfront.

The Best Fabric Ink for Screen Printing

Considerations for Fabric Printing

When seeking the best fabric ink for screen printing, consider factors such as:

- Fabric type (natural vs. synthetic)

- Desired finish (matte, glossy, etc.)

- Wash resistance

- Stretch properties of the fabric

Top Choices for Fabric Printing

Some of the best inks for screen printing on fabric include:

- High-quality plastisol inks

- Soft-hand water-based inks

- Discharge inks for dark fabrics

- Specialty inks for unique effects

Innovations in Screen Printing Inks

New Formulations

The search for the best ink for screen printing continues to drive innovation, with new formulations offering improved performance and environmental benefits.

Hybrid Inks

Some manufacturers are developing hybrid inks that combine the best properties of different ink types, potentially offering a new contender for the best ink for screen printing.