Key Takeaways for Fluorescent Plastisol Ink Printing

- Fluorescent plastisol ink gives you most colour impact, mainly on darkish clothes and when revealed over a white beneath-base.

- Choose your mesh, display screen, and base cautiously for the high-quality combination of image sharpness and ink coverage.

- Cure inks to the encouraged temperature for wash sturdiness—in no way wager!

- Store your ink in sealed containers, at room temperature, and away from direct sunlight to keep creamy consistency.

- Test everything: do print and wash exams to test treatment, adhesion, and color vibrancy before committing to full production.

- Consider non-phthalate ink for safer, greater eco-friendly print runs—specially for large or regulated orders.

- Vary mesh counts and base techniques for the great hand sense, opacity, and insurance.

- Always deal with your workspace, screens, and mesh as important equipment for finished first-rate.

- Fluorescent colorings aren’t simply brilliant—they’re a superpower for branding, activities, sports, and assertion prints.

Want more pointers or have questions on specific inks or techniques? Drop your feedback underneath—let’s remove darkness from the sector of display printing collectively!

Unleashing Vivid Brilliance: A Deep Dive Into Fluorescent Plastisol Ink for Screen Printing

Want your next screen print to command attention? Craving shades that don’t just pop, but undoubtedly glow? Look no similarly than fluorescent plastisol ink. This article is your complete guide to the technological know-how, craft, and practical application of fluorescent plastisol inks in display screen printing. Whether you’re a pro display printer, curious hobbyist, or simply captivated with captivating colour, you’ll discover why those inks are converting the game. We’ll unpack the whole lot from their chemistry to curing, with lots of realistic recommendations, pinnacle techniques, and pro hacks along the way. If you want prints that stand out—actually and figuratively—that is one blog submit you really shouldn’t omit.

Article Outline

- What Makes Fluorescent Plastisol Ink So Unique in Screen Printing?

- How Does Plastisol Ink Work, and Why Choose It Over Water-Based Ink?

- Which Fluorescent Colors Are Most Popular? (Fluorescent Yellow, Fluorescent Pink, Fluorescent Red)

- How Should You Prepare Your Screen and Mesh for Fluorescent Prints?

- What’s the Importance of Under-Base in Fluorescent Plastisol Printing?

- How Do You Print on Dark Garments With Plastisol Inks?

- Direct Printing vs. Under-Base: What’s Best for Fluorescent Inks?

- What Makes Non-Phthalate Inks a Safer Option?

- How to Achieve Proper Curing and Fusion at the Right Temperature?

- Best Practices for Storing and Handling Fluorescent Plastisol Ink

1.What Makes Fluorescent Plastisol Ink So Unique in Screen Printing?

There’s regular ink, after which there’s fluorescent plastisol ink. Let’s face it: in case you want your print to grab attention from throughout the room, you need critical shade energy. Fluorescent plastisol is formulated for optimum brilliance, performed by using unique dye blends that reflect ultraviolet light. This offers your print an almost sparkling impact, in particular under blacklight, and a vibrancy in sunlight hours that traditional ink truly can’t match.

Unlike standard plastisol ink, the fluorescent version takes shade to extremes. It’s all approximately luminosity, attractive colorings, and a creamy consistency that’s easy for both guide and automated display printing. Whether you’re printing a fluorescent yellow shirt for a fun run or a batch of bright fluorescent purple emblems for a nightclub occasion, the shade impact is unbeatable.

Another component that makes fluorescent plastisol ink so suited? Versatility. These inks adhere properly to more than a few fabrics—from cotton and polyester to nylon—and can provide notable insurance with smart technique. For screen printers aiming for top class consequences, fluorescent plastisol ink elevates any product from mundane to need to-see.

2.How Does Plastisol Ink Work, and Why Choose It Over Water-Based Ink?

Curious why plastisol is the display printing industry standard? Unlike water-based totally ink, plastisol ink doesn’t dry by way of evaporation. Instead, it ought to be heated to a right cure temperature, inflicting the PVC resin and plasticizer in the ink to fuse right into a long lasting, bendy film. That way open display time is by no means a hurry—you can work at your personal tempo, knowing the ink gained’t clog your mesh mid-project.

Because of this mechanism, plastisol ink is the go-to for each beginners and high-quantity manufacturing runs. It’s forgiving, shops well at room temperature, and doesn’t dry out in the display. When it comes to fluorescent plastisol inks, this advantage is doubled—brilliant colour with all of the advantages of plastisol chemistry and method flexibility.

What’s extra, plastisol ink presents advanced opacity and insurance as compared to most water-primarily based options, especially on darkish cloth. It’s less complicated to attain that signature vibrant appearance with fewer passes. The simplest seize? For a tender hand experience, care have to be curious about ink thickness and mixing—something pro printers master thru careful test prints, mesh choice, and beneath-base technique.

3.Which Fluorescent Colors Are Most Popular? (Fluorescent Yellow, Fluorescent Pink, Fluorescent Red)

Let’s communicate colour psychology—and why fluorescent yellow, fluorescent crimson, and fluorescent crimson rule the roost. Fluorescent yellow is the reigning champion for high visibility, ideal for protection shirts, athletic gear, and event branding in which immediately recognition matters. It’s the last interest-getter, assured to make your print pop.

Fluorescent crimson is a favourite for style, tune, and nightlife—hanging, ambitious, and vibrantly playful. Whether you’re printing for a summer season competition or a charity run, it’s a color impossible to ignore.

Fluorescent purple, in the meantime, gives a completely unique twist—greater competitive than crimson, extra extreme than trendy pink, and with a glow that’s best for sports activities groups, promotional products, or standout photos on each white and dark clothes. Each fluorescent ink within the collection plastisol range possesses high opacity, creamy consistency, and natural visual impact. Be certain to choose the right coloration in your print’s message, and constantly check for coverage and appearance, as these brilliant colours may be sensitive to variations in below-base and material

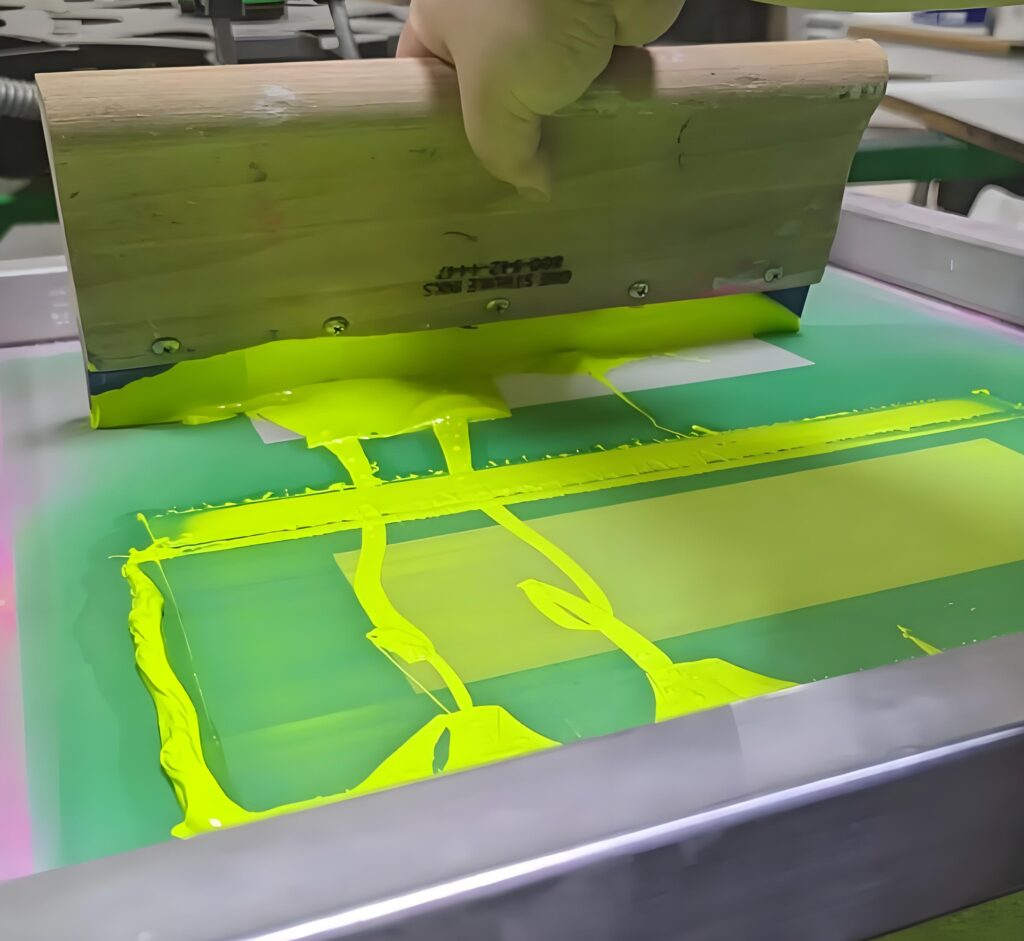

4.How Should You Prepare Your Screen and Mesh for Fluorescent Prints?

Preparation is the whole lot. For fluorescent plastisol ink, start with a high-anxiety display screen and a mesh matter suitable on your ink and layout element. Too coarse a mesh, and also you’ll lose image sharpness or waste ink. Too exceptional, and you danger terrible coverage—mainly with excessive-opacity ink formulations.

Always degrease your display earlier than making use of emulsion. Any residue can restrict stencil formation or switch problems onto the print. The creamy consistency of plastisol ink method it passes without problems through maximum meshes, however the precise mesh count number for fluorescent plastisol is generally among 110T and 160T for ordinary images.

The frame tension, mesh, and display screen prep all have an impact on the very last excellent of your fluorescent print. With a nicely-organized display, your plastisol ink will transfer most efficiently, deliver even coverage, and maintain crucial information—important for high-evaluation, high-impact prints wherein colour is everything.

5.What’s the Importance of Under-Base in Fluorescent Plastisol Printing?

Here’s a pro secret: under-base makes or breaks your fluorescent print, particularly on dark garments. When the usage of fluorescent plastisol ink on whatever however white material, always lay down a white below-base first. This acts as a reflective surface, preventing the underlying fabric from dulling the ink’s brilliance and ensuring your fluorescent shades stay brilliant.

Without an underneath-base, fluorescent purple or yellow can appear dull or muddy, as the fabric dye absorbs a number of the colour energy. The process normally entails first applying the beneath-base, speedy flashing it to gel (not absolutely cure) it, then overprinting with your preferred fluorescent ink whilst the bottom is still warm for first-rate fusion.

This step-with the aid of-step technique guarantees you get continuously high-opacity, luminous outcomes. It takes a bit exercise (and some well-timed flashes), however the payoff is huge in both perceived value and shade intensity.

6.How Do You Print on Dark Garments With Plastisol Inks?

Printing on dark garments? Don’t pass the prep. The key is maximizing opacity and colour brightness. Apply your white beneath-base for fluorescent yellow or crimson, and make certain your plastisol ink for display is formulated for high insurance.

Carefully pick out mesh and squeegee—too much stress will flatten the ink, too little will leave gaps. For dark shirts or hoodies, a thicker deposit of ink or two passes (with a flash in between) facilitates ensure full vibrancy. Some display screen printers will experiment with mixture strategies, creating gradients or layering more than one fluorescent inks for specific multi-coloration outcomes.

Don’t forget about to check! Every garment and every display screen behaves a touch otherwise. Do a print test on scrap fabric to check for color, hand, and wash durability before transferring to full production. A fluorescent print on a darkish floor is an artwork in itself, but with interest to base, ink system, and system, you’ll obtain outcomes that rival the exceptional top rate display printing elements out there

7.Direct Printing vs. Under-Base: What’s Best for Fluorescent Inks?

You would possibly ask: should I print fluorescents “direct” onto the material, or over an below-base? The answer depends to your cloth and desired end result. Direct printing—making use of fluorescent plastisol ink immediately to a white or mild blouse—can be effective, ensuing in a notable tender hand and much less ink buildup. However, the true glow of fluorescent ink shines when a white under-base is used, specifically on dark or mixed garments.

The beneath-base acts as a canvas, reflecting transmitted mild so that the fluorescent dye isn’t misplaced to the material’s undertone. For polyester or combination substances, an beneath-base additionally helps prevent dye migration, that can damage your fluorescent picture. Whether you’re printing a single-coloration occasion shirt or a complex, multi-color photograph, aspect in an under-base on every occasion you want maximum shade brilliance.

Pro tip: When the use of direct printing for light fabric, do a check run first and examine with an below-base version to peer how the photograph and color pop. Sometimes, the difference is dramatic—in particular beneath UV or with high-coverage graphics.

8.What Makes Non-Phthalate Inks a Safer Option?

Safety is a warm subject matter. More display screen printing plastisol ink producers are transferring to non-phthalate formulations. This means the ink is made with out certain plasticizers that can be fitness or environmental hazards. If you produce big-volume apparel (assume school shirts, kidswear, or uniforms), deciding on non-phthalate ink could make your product extra attractive to eco-conscious or regulation-pushed customers.

Non-phthalate inks behave almost identically to conventional plastisol ink, with the equal creamy consistency, clean curing, and flexibility. The shift to those inks is a win-win: you maintain extremely good print fine and sense appropriate knowing your product is safer for the quit consumer—and the environment. Always verify your display printing supplies in case you need to marketplace your prints as non-phthalate, and keep a watch out for changing standards for your region.

9.How to Achieve Proper Curing and Fusion on the Right Temperature?

Curing is the entirety. Plastisol ink (together with fluorescent plastisol) only achieves maximum wash durability and flexibility after rising to its correct fusion temperature—typically 320°F (one hundred sixty°C), although you must usually check your specific product’s label. If you underneath-therapy, the ink will crack, wash out, and disappoint. Over-remedy, and the print can also grow to be brittle, dropping hand and luxury.

Use a dependable conveyor dryer, or at minimal, a outstanding flash remedy unit to get your prints up to temperature. An infrared thermometer or take a look at strips are valuable for ensuring your plastisol ink for display screen has absolutely fused, both at the surface and deep into the print’s base.

A nicely cured fluorescent plastisol print washes brilliantly and retains its glow for the garment’s lifetime. Never pass check prints! A short wash and stretch take a look at will verify your ink is cured, fused, and production-ready.

10.Best Practices for Storing and Handling Fluorescent Plastisol Ink

Smart garage guarantees vibrant prints whenever. Keep your plastisol ink—mainly five gallon manufacturing sizes—sealed tightly in unique boxes at room temperature. Avoid direct daylight and severe swings in temperature, as these can have an effect on the texture, colour accuracy, and creamy consistency of the ink.

For exceptional effects, stir your ink thoroughly before every use to maintain foremost combo and texture. Older fluorescents can also thicken in storage; a quick mechanical blend or mild warmness will restore their creamy go with the flow. Always label opened ink with a date and color for smooth identity for the duration of busy manufacturing runs.

Finally, clean up spills or drips quick with a appropriate display purifier. Even small amounts of fluorescent dye can stain, so maintain your paintings location neat and prepared. Smart dealing with extends the shelf lifestyles of your top rate inks and maintains your production silky clean.