Metallic Gold Plastisol Ink for Screen Print: High opacity gold plastisol ink for vibrant screen prints. Formulated for low bleed on polyester garments. Creamy, metallic shimmer. Cures quickly.

Table of Contents

Understanding Metallic Gold Plastisol Ink

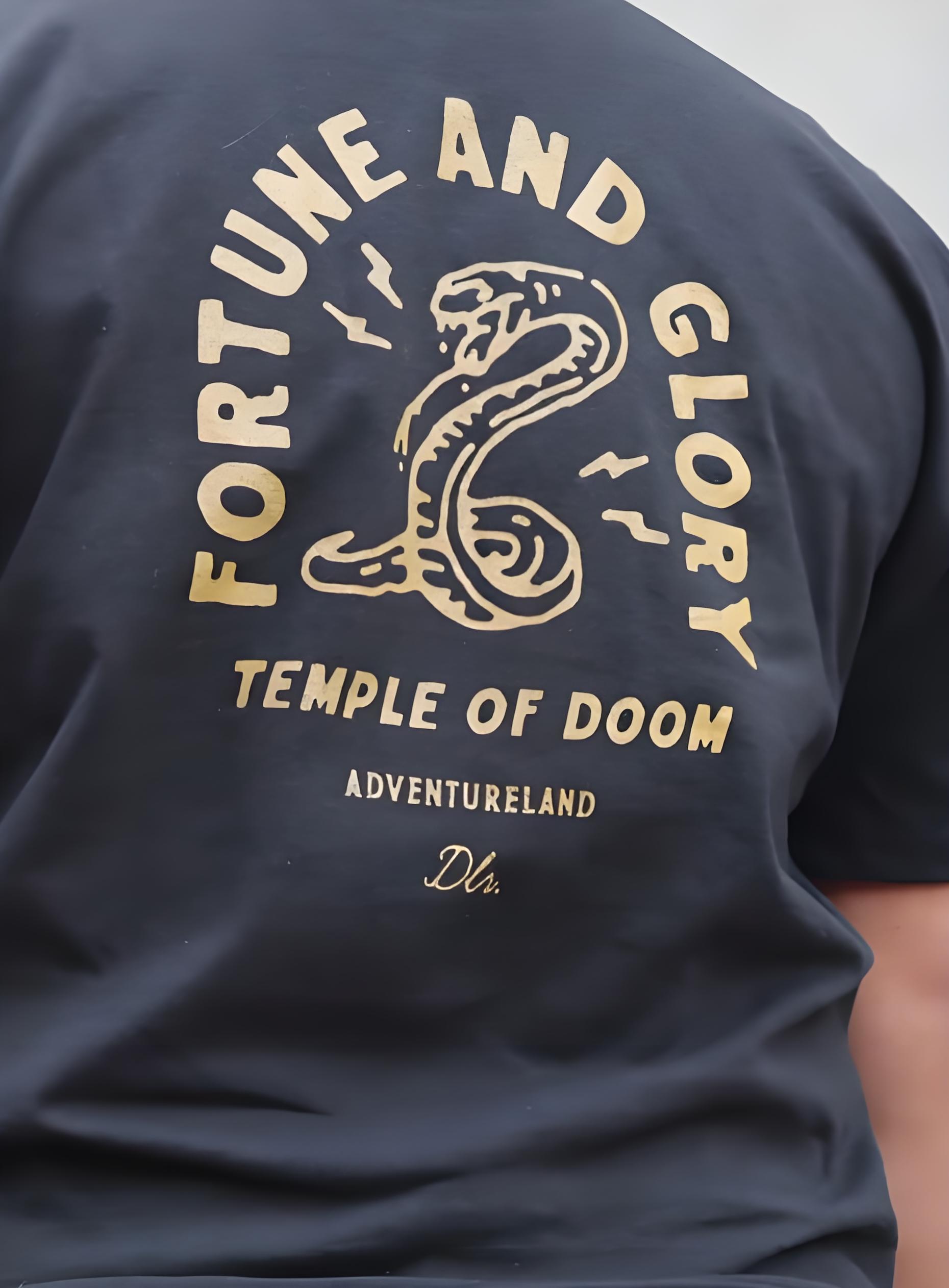

Metallic gold plastisol ink is a specialized screen printing ink that contains fine gold metallic particles suspended in a plastic-based carrier. This unique composition creates a lustrous, reflective finish on printed fabrics, making it ideal for decorative and high-visibility applications. The ink maintains its brilliance across multiple washes when properly cured.

Key characteristics of metallic gold plastisol ink:

- High opacity for excellent coverage on dark fabrics

- Metallic flakes suspended in a durable plastisol base

- Requires heat curing between 270-320°F for proper bonding

- Excellent flexibility when cured, preventing cracking

Applications and Uses

This specialty ink performs exceptionally well for:

- Athletic team uniforms and sports apparel

- Fashion garments requiring metallic accents

- Promotional products and event merchandise

- High-end branding on apparel and accessories

Top recommended substrates include:

- 100% cotton fabrics

- Cotton-polyester blends

- Performance fabrics (with proper pretreatment)

Recommended Products

| Product | Features | Best Uses | Purchase Link |

|---|---|---|---|

| Sunshine Metallic Ink | Highest metallic reflection, quick curing | Performance wear, fashion apparel | View product |

| Dune Metallic Ink | Softer hand feel, moderate reflection | Everyday apparel, cotton blends | View product |

| Champagne Gold Ink | Subtle metallic finish, excellent printability | Luxury items, delicate fabrics | View product |

Optimal Printing Conditions

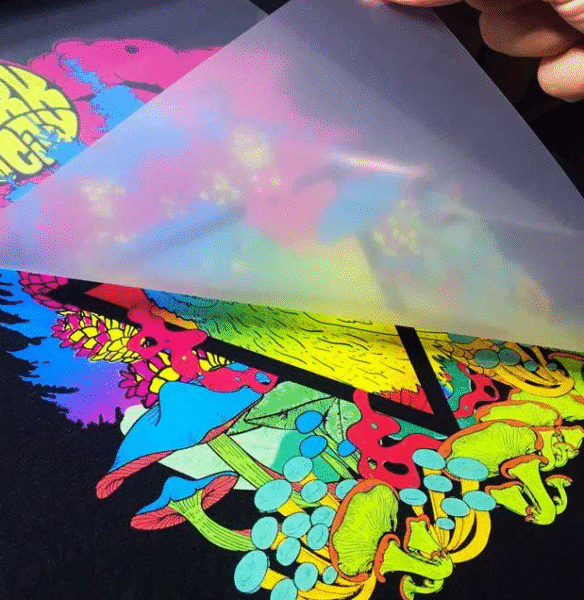

For best results when screen printing with metallic gold plastisol ink:

- Screen selection: Use 90-125 mesh screens for proper metallic flake dispersion

- Squeegee selection: 70-75 durometer for effective ink deposit

- Printing pressure: Medium firm pressure (not excessive)

- Curing parameters: 270°F (132°C) for 60 seconds minimum

- Recommended underbase: White plastisol for dark fabrics

Note: Some metallic inks may require slight modification (reducer or softener) depending on fabric type and desired hand feel.

Maintenance and Storage

Proper handling ensures consistent printing performance:

- Stir thoroughly before use to redistribute metallic particles

- Store in airtight containers at room temperature

- Avoid cross-contamination with non-metallic inks

- Clean screens immediately after use to prevent ink drying in mesh

For more detailed application techniques for specialty fabrics, visit our guide to advanced screen printing methods on dark substrates.