Screen printing with fluorescent ink has become increasingly popular for creating eye-catching, vibrant designs that demand attention.

Key Points to Remember:

- Fluorescent inks require proper mixing and preparation for optimal results

- Choose the right mesh count for your specific ink type and design

- Ensure proper curing temperatures to maintain vibrancy and durability

- Test prints on intended fabrics before full production

- Consider using an under-base for dark garments

- Maintain consistent pressure and off-contact distance while printing

- Store inks properly to maintain their properties

- Use appropriate safety equipment and ventilation

- Regular maintenance of screens and equipment is essential

- Consider environmental impact when selecting ink types

This comprehensive guide will walk you through everything you need to know about using fluorescent and plastisol ink in screen printing, from selecting the right materials to achieving perfect results. Whether you’re a beginner or experienced screen printer, this article will help you master the art of working with fluorescent inks.

What Makes Fluorescent Screen Printing Ink Special?

Fluorescent display screen printing ink is formulated with unique pigments that mirror extra light than preferred inks, developing that distinctive “glow” effect. These inks are designed to be extra colourful and attractive than traditional colors, making them best for attention-grabbing designs.

The precise residences of fluorescent ink make it in particular appropriate for developing ambitious statements on garments. When properly cured, those inks can provide exceptional opacity and insurance, even on darkish garments.

Types of Fluorescent Inks: Plastisol vs. Water-Based

Plastisol ink stays the maximum popular desire for fluorescent screen printing, supplying superb opacity and durability. These inks include PVC debris suspended in plasticizing emulsion, growing a thick, creamy consistency that works properly on maximum fabrics.

Water-based inks offer a tender-hand sense and are extra environmentally friendly. However, they may be more hard to paintings with when printing fluorescent colorings, in particular on darkish fabrics where multiple layers can be wished for correct insurance.

How to Choose the Right Fluorescent Colors for Your Design?

When deciding on fluorescent colours, keep in mind the effect you need to gain. Fluorescent yellow and fluorescent green are usually the most vibrant, at the same time as fluorescent red and fluorescent orange offer striking options. Fluorescent blue can create thrilling effects, specifically while combined with different neon sun shades.

The desire of color need to additionally do not forget the fabric coloration and sort. Some fluorescent inks may additionally require an beneath-base on dark garments to gain top-quality vibrancy.

What Fabrics Work Best with Fluorescent Inks?

Cotton stays the most famous preference for fluorescent screen printing, providing exceptional ink absorption and durability. However, these inks also can work properly on polyester, blend fabric, or even materials like rayon and linen.

Different fabrics can also require specific mesh counts and curing temperatures. Always take a look at your ink at the supposed material before beginning a complete production run.

Common Challenges When Working with Fluorescent Inks

One of the biggest challenges in fluorescent screen printing is reaching constant opacity throughout the layout. These inks often require a thicker deposit than widespread plastisol inks, which may necessitate using decrease mesh counts.

Another not unusual issue is right curing. Fluorescent inks have to be cured at particular temperatures to save you scoring and make sure sturdiness thru washing.

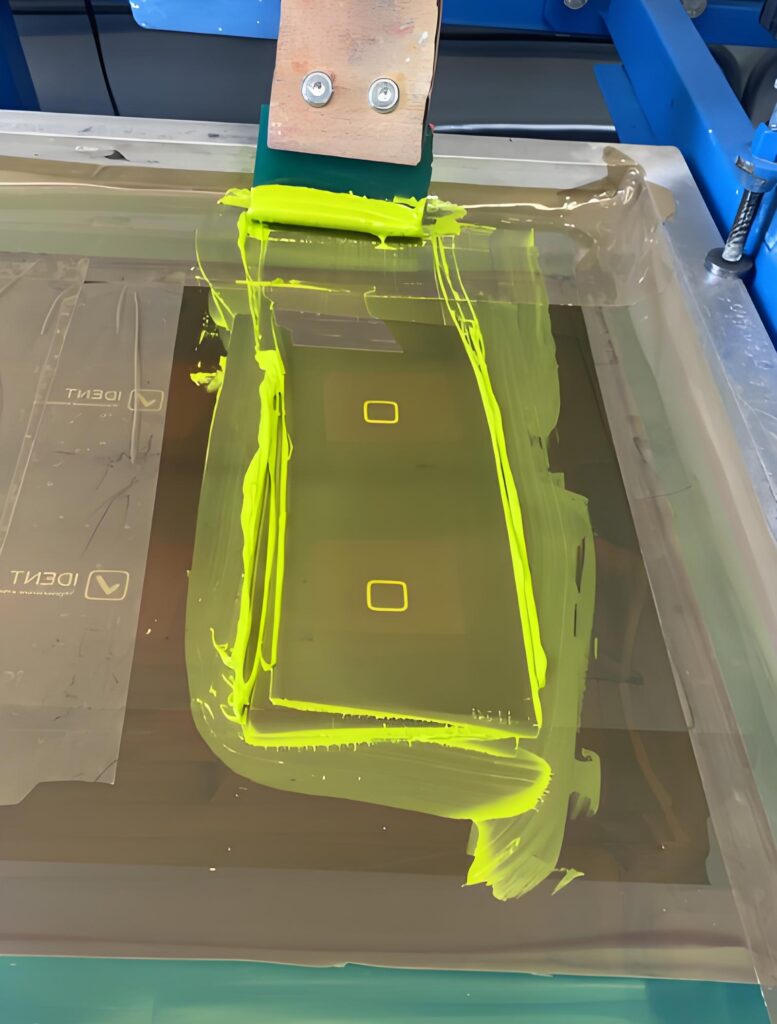

Tips for Achieving Perfect Prints with Fluorescent Ink

Success with fluorescent display screen printing starts with right screen education. Use appropriate emulsion and mesh counts for your specific ink kind. For plastisol fluorescent inks, a mesh be counted between one hundred ten-156 normally works well.

Maintain steady strain throughout printing and make certain right off-touch distance. Multiple prints can be essential to obtain desired opacity, particularly on darkish shirts.

How to Properly Cure Fluorescent Inks?

Proper curing is critical for fluorescent ink durability. Most plastisol fluorescent inks cure at temperatures between 320-330°F (one hundred sixty-166°C). Use a laser temperature gun to verify right curing temperature.

Insufficient curing can lead to washing problems, even as immoderate heat can motive the colors to dull or scorch the material.

Mixing and Storage of Fluorescent Inks

Fluorescent inks ought to be thoroughly blended before use to make certain regular colour and opacity. Store inks in a fab, dry area and keep containers sealed whilst not in use.

For computerized printing operations, everyday mixing at some stage in manufacturing enables preserve constant ink residences.

Environmental and Safety Considerations

Many modern-day fluorescent inks are non-phthalate formulations, making them safer for both printers and end-customers. When operating with those inks, make certain proper ventilation and wear appropriate shielding device.

Consider using water-based alternatives whilst environmental concerns are paramount, though those may also require different printing techniques.