Eco-conscious printing is no longer a niche—it’s becoming an industry standard. As sustainability expectations rise across fashion, textiles, and packaging, eco-friendly plastisol ink is emerging as a key solution.

Let’s explore what’s driving this shift and how businesses can benefit.

What Is Eco-Friendly Plastisol Ink?

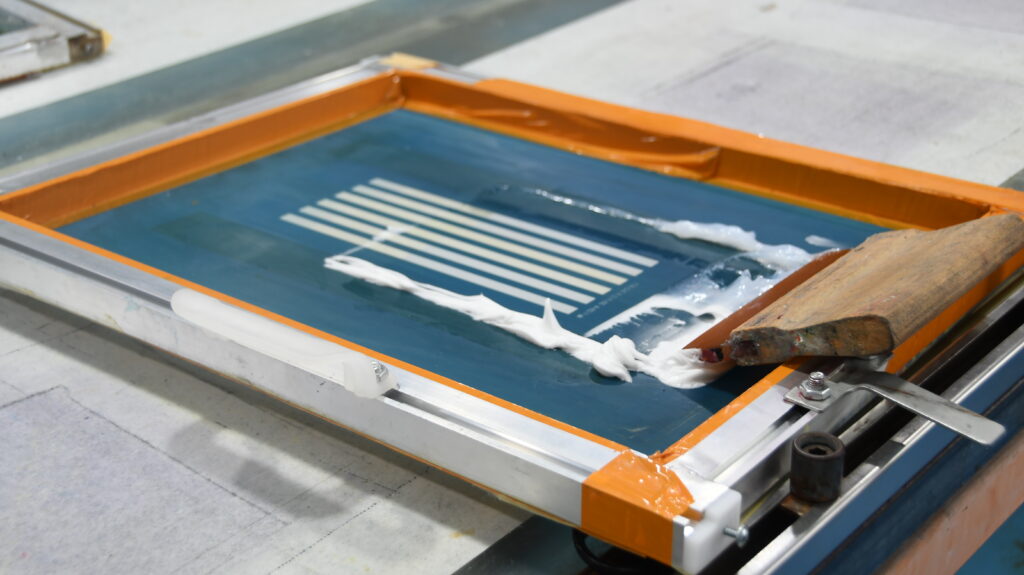

Traditional plastisol inks often contained harmful plasticizers and chemicals. In contrast, modern eco-friendly plastisol ink formulations eliminate or significantly reduce toxic substances like phthalates and heavy metals. These inks are safer for workers, better for the environment, and increasingly in demand by conscious consumers.

Why Demand Is Rising

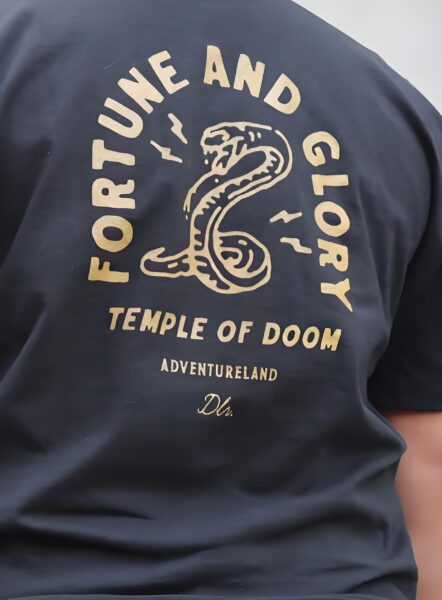

- Consumer Preference: A growing number of consumers actively choose products that are environmentally friendly. Apparel printed with eco-certified inks is gaining a competitive edge.

- Corporate ESG Commitments: Brands are aligning with sustainability goals, often prioritizing eco-friendly materials to meet environmental, social, and governance (ESG) targets.

- Regulatory Pressure: Government regulations—especially in the EU, US, and parts of Asia—are banning hazardous chemicals, forcing companies to reformulate their inks.

- Retail & Brand Standards: Retailers now require suppliers to meet eco-standards, including using compliant inks and certified production methods.

Current Market Landscape

- Market Size: Estimated at $1.2 billion in 2023, the eco-plastisol segment is projected to grow at a 9.8% CAGR through 2030.

- Regional Hotspots: Asia-Pacific leads the market with a 42% share, driven by robust textile manufacturing in countries like India and Vietnam.

- Adoption Drivers:

- 68% of global brands prioritize sustainable packaging and production.

- 74% of Gen Z consumers are willing to pay more for eco-labeled apparel.

- Patagonia reduced supply chain emissions by 18% after switching to phthalate-free inks.

Key Innovations Fueling Growth

- Bio-Based Plasticizers: New formulations using plant-derived plasticizers reduce VOC emissions by up to 90%.

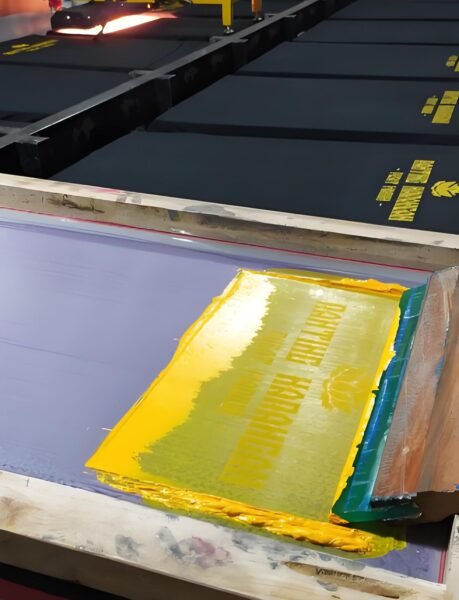

- Recyclable Ink Systems: Closed-loop recycling technologies now recover up to 85% of waste ink, minimizing landfill impact.

- AI-Driven R&D: Artificial intelligence is accelerating the development of new ink chemistries, cutting formulation timelines by 40%.

Opportunities for Businesses

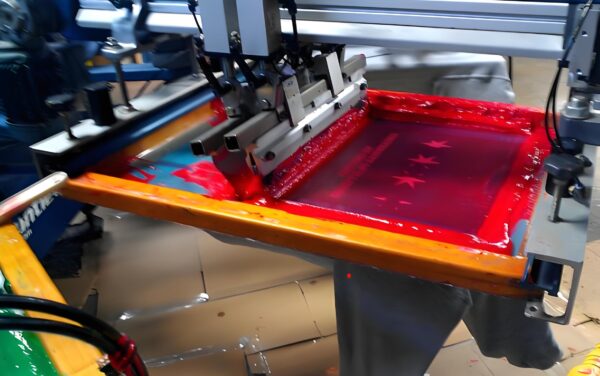

- Textile and Apparel: Sportswear, children’s clothing, and medical textiles benefit greatly from safer, flexible inks.

- SME Market: Small and mid-sized print shops have vast untapped potential, despite only 22% currently adopting eco-plastisol.

- Collaborations: Partnerships with environmental organizations or certification bodies can help validate eco-claims and build trust.

- Education & Branding: Communicating environmental advantages clearly to customers boosts brand loyalty and perceived value.

Challenges to Overcome

- Higher Cost: Eco-plastisol inks currently cost 15–20% more, though savings in wastewater treatment and compliance offset this over time.

- Performance Skepticism: Some printers still question whether eco formulations match traditional inks in opacity or durability.

- Global Compliance Complexity: Regulatory requirements vary by region, making standardization a challenge for global suppliers.

- Greenwashing Risk: Without proper verification, some suppliers falsely market products as eco-friendly—damaging consumer trust.

What’s Ahead

The future is clear: eco-friendly plastisol ink will play a central role in the evolution of screen printing. As regulations tighten, technology advances, and consumers demand sustainable options, the entire industry will shift in this direction.

- More certifications will become standard practice.

- Closed-loop recycling systems will be integrated into major production chains.

- Pricing will stabilize as demand increases and materials scale.

Conclusion

The transition to eco-friendly plastisol ink is not only good for the planet—it’s a smart move for forward-thinking businesses. Early adopters stand to gain from enhanced brand value, regulatory readiness, and customer loyalty. Now is the time to explore cleaner, safer alternatives and position your company for the future of sustainable printing.