Learn all about the squeegee silkscreen in this guide, including the best angles, how to use it without streaks, and much more!

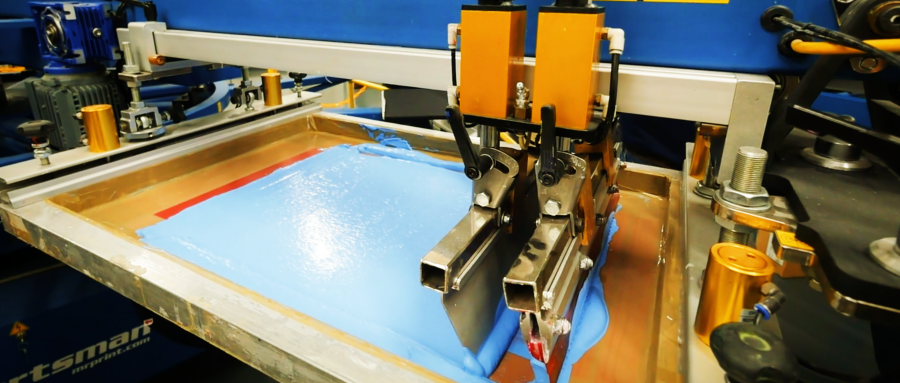

Screen printing is a versatile and popular method for creating vibrant, long-lasting designs on a wide range of materials. At the heart of this process lies a tool that many printers may overlook but is crucial to achieving flawless prints: the squeegee silkscreen. Whether you’re a beginner or an experienced screen printer, understanding how to properly use a squeegee is essential for achieving high-quality results.

In this comprehensive guide, we will explore various aspects of squeegee silkscreen, including its correct usage, techniques for avoiding streaks, the best angle for squeegee silkscreen, and more.

Table of Contents

What is the Best Angle for Squeegee for Screen Printing?

The angle at which you hold your squeegee silkscreen can have a significant impact on the quality of your print. To achieve smooth and even coverage of ink across your screen, you need to find the ideal angle that works best for the design you’re printing and the ink you’re using.

The most commonly recommended angle for a squeegee in screen printing is between 45° and 60°. This angle allows for proper pressure distribution while ensuring that the ink is pushed through the mesh evenly. Let’s break it down further:

- 45° Angle: A squeegee at this angle allows you to apply enough pressure without putting too much strain on your wrist or arms. It’s ideal for lighter inks and when you want to create fine, delicate prints.

- 60° Angle: A slightly steeper angle of 60° is more commonly used for thicker inks, such as plastisol, or when you need to apply more pressure to push the ink through the screen mesh.

It’s important to note that the angle of the squeegee silkscreen can vary depending on the type of screen, mesh count, and ink being used. As you practice screen printing, you’ll develop a feel for the best angle that works for your specific projects.

How Do You Use a Squeegee Without Streaks?

Using a squeegee silkscreen effectively involves more than just applying the right pressure; it also requires controlling the motion and technique to prevent streaks, which can ruin your prints. Here are a few tips to help you use your squeegee without streaks:

- Consistent Speed and Pressure: Maintain a consistent speed when pulling the squeegee across the screen. If you go too fast, you risk not applying enough pressure to push the ink through. Conversely, moving too slowly can cause excess ink to pool, leading to streaks.

- Use Even Pressure: Applying uneven pressure during the print stroke can lead to inconsistent ink distribution and cause streaking. Ensure you are applying equal pressure across the entire length of the squeegee.

- Right Squeegee Angle: As we discussed earlier, the right angle is key. Too steep or too shallow an angle can result in ink streaks. Experiment with angles between 45° and 60° to find the sweet spot that works best for your design.

- Proper Ink Consistency: If the ink is too thick, it can leave behind unwanted streaks. Make sure your ink has the right viscosity for the type of design you’re printing. Thinner inks flow more easily, reducing the chance of streaks.

- Prevention is Better Than Cure: Before starting your print run, make sure your screen is clean, and the mesh is free from any blockages that could affect the ink flow.

By combining the right angle, consistent speed, and the correct amount of pressure, you can significantly reduce the chances of creating streaks in your screen printing.

How to Hold a Squeegee for Screen Printing?

Knowing how to properly hold a squeegee silkscreen is another essential skill for achieving great results in screen printing. Improper grip can lead to uneven prints and physical discomfort during longer print runs.

Here’s how to hold a squeegee correctly for screen printing:

- Grip Style: Place your hands about 6 to 8 inches apart on the squeegee. One hand should grip the handle firmly, while the other should support the top or bottom of the squeegee, depending on your preference. This will give you better control over the squeegee as it moves across the squeegee silkscreen.

- Hand Placement: Your dominant hand should generally be at the back of the squeegee, where you apply most of the force. Your non-dominant hand should be closer to the blade to stabilize the motion and ensure that the squeegee moves in a straight line.

- Relax Your Grip: While it’s important to maintain control, don’t grip the squeegee too tightly. Tension in your hands or wrists can cause discomfort during long print sessions and lead to unnecessary strain.

- Posture: When using a squeegee, your posture is important. Stand comfortably, and make sure you are at the right height so that you can apply even pressure without straining your back or arms. Use both hands to guide the squeegee with a smooth, consistent motion.

Proper hand placement and posture will give you better control over the squeegee, allowing you to create more consistent prints with less effort.

What is Squeegee in Silkscreen Printing?

In screen printing, the squeegee silkscreen is a tool used to push ink through the mesh of the screen onto the printing surface (such as fabric, paper, or other substrates). The squeegee has a rubber or polyurethane blade that presses the ink through the screen’s mesh openings, leaving the desired design on the substrate.

The key features of a squeegee in silkscreen printing include:

- Blade Material: Most squeegees feature a rubber or urethane blade. The blade’s material affects the amount of pressure needed to push the ink through the mesh and also determines the smoothness of the print.

- Shape: The blade of the squeegee can have various profiles, including square, rounded, or beveled. The shape of the blade affects the ink flow and print quality.

- Handle: The squeegee handle is usually made of wood, metal, or plastic. It provides grip and stability during the printing process.

The squeegee silkscreen is a crucial part of the screen printing process, and understanding how to use it properly can significantly improve the quality and consistency of your prints.

How to Coat a Screen with a Squeegee?

Coating a screen with emulsion is one of the first steps in squeegee silkscreen. It requires precision and the right technique to ensure a smooth and even coat that will yield the best prints.

To coat a screen with a squeegee, follow these steps:

- Prepare the Screen: Make sure the screen is clean and free from dust, grease, or oils. Any contaminants can affect the quality of your coating.

- Apply Emulsion: Pour a small amount of emulsion along the top of the screen. You can use a scoop coater for this, but some printers use a squeegee to apply the emulsion evenly.

- Coat the Screen: Hold the squeegee silkscreen at a 45° angle and gently spread the emulsion across the screen. Apply even pressure, ensuring the emulsion covers the mesh without dripping. Make sure the emulsion layer is thin and uniform.

- Dry the Screen: After coating, let the screen dry in a dark room to avoid exposure to light. Once dry, the screen is ready for exposure.

By using a squeegee to coat your screen, you ensure a smooth, even application of emulsion that will lead to a high-quality screen print.

What is the Most Common Squeegee Size?

The most common squeegee silkscreen size is around 12 to 14 inches, but this can vary depending on the size of your screen and the design you’re printing. The size of the squeegee you use affects the amount of ink you can push through the mesh, which, in turn, impacts the speed and ease of printing.

- 12-14 inches: Ideal for most standard screen printing jobs, such as t-shirts and posters. This size allows for effective ink distribution across the design without excessive pressure.

- Larger Sizes (16-18 inches): These are typically used for larger prints or industrial-scale printing, where a larger squeegee can cover more area quickly.

- Smaller Sizes (6-10 inches): Smaller squeegees are useful for fine detail work, like printing small designs or logos.

Choosing the right squeegee size depends on your specific project. If you are printing small designs, a smaller squeegee is better. For larger prints, opt for a larger squeegee.

Conclusion

The squeegee silkscreen is an essential tool in screen printing, and mastering its use can elevate your print quality and efficiency. Whether you’re perfecting your technique to avoid streaks, experimenting with different squeegee angles, or choosing the right size for your print job, understanding the role of the squeegee in the screen printing process is crucial.

With the right technique and the appropriate tools, you can create high-quality prints that are vibrant and long-lasting. Whether you’re a beginner or a seasoned pro, taking the time to perfect your squeegee