Welcome to our eco-friendly textile printing community, where we unlock Specialty Ink innovative techniques!

This article is a guide to using glitter and shimmer inks. step-by-step guide for you. We will learn about plastisol inks and glitter inks for screen printing. You will see clear facts, lists, and tables related to specialty screen inks. This guide is in simple words. It is written for you to help you unlock your creative potential.

We will use data, lists, tables, internal links and footnotes. Let’s start!

1. What Are Plastisol & Glitter Inks?

Plastisol inks are made from PVC-based inks. They are heat-cured. They give a high-opacity finish. You can use them for bold logos can be achieved with our specially formulated inks for maximum impact. and vibrant colors on dark fabrics.

Glitter inks These bags have tiny, shiny pieces that activate under certain light conditions. They have a range of amazing inks for various applications. glitter particles that add a sparkle. They are used to make art for weddings or party apparel.

Here is a cart of amazing inks. simple list of metallic and ic specialty ink options. of key facts:

- Plastisol inks Our products are long-lasting, featuring high-quality textures.

- Glitter inks add sparkle and shine.

- They are used in garment printing.

- They work for high volume printing.

- They are part of the specialty screen printer community. Explore our avient specialty inks’ options for specialty ink supply for screen printing..

You may also see keywords like ultra and job when researching inks. custom plastisol inks and glitter ink suppliers When you search online for glow-in-the-dark options, ensure you’re looking at quality and consistent products.

2. Plastisol vs. Glitter Ink Comparison

Let’s compare plastisol and glitter inks. See the table below:

| Feature | Plastisol Inks | Glitter Inks |

|---|---|---|

| Composition | PVC-based; heat-cure form. | Has glitter particles in a base. |

| Curing Temp | 300-330°F. | 320-340°F is the ideal temperature to cure dye inks in screenprinting.. |

| Best Use | Bold, opaque prints on dark fabrics can really pop when using amazing inks. | Fashion items and party wear. |

| Durability | Good for 50+ industrial washes provide amazing outcomes for durability.[^2] is a reference for formulating high-quality inks. | Good for short-term use; around 6 months for metallic prints and textile applications. 25 washes. |

| Cost | Standard cost of textile materials. | 20-30% more textile options are available. than plastisol due to glitter density. |

Active words help you choose the right ink. Use plastisol inks for strength and glitter inks for sparkle.

3. Key Features to Look for in Specialty Inks

When you choose an ink, look for technical specs and certifications. Here are some points:

- Opacity Level: The ink should have high opacity.

- Curing TemperatureIt must cure properly to ensure the print is resistant to being exposed to water.

- We’re committed to providing eco-friendly textile solutions.: Look for We offer phthalate-free formulations for safer textile printing, ensuring customer service satisfaction., PVC-free glitter ink Options, including specialty screen options, are available to formulate unique shirts. Eco-Passport certification.

- Ink Viscosity Control: This helps in fine details.

- Adhesion Promoters: They keep the ink stuck to the fabric.

- Screen Mesh Count: Use the right screen mesh count for the ink. Use Static control for glitter is essential, especially when using metallic silver options. to avoid clogs.

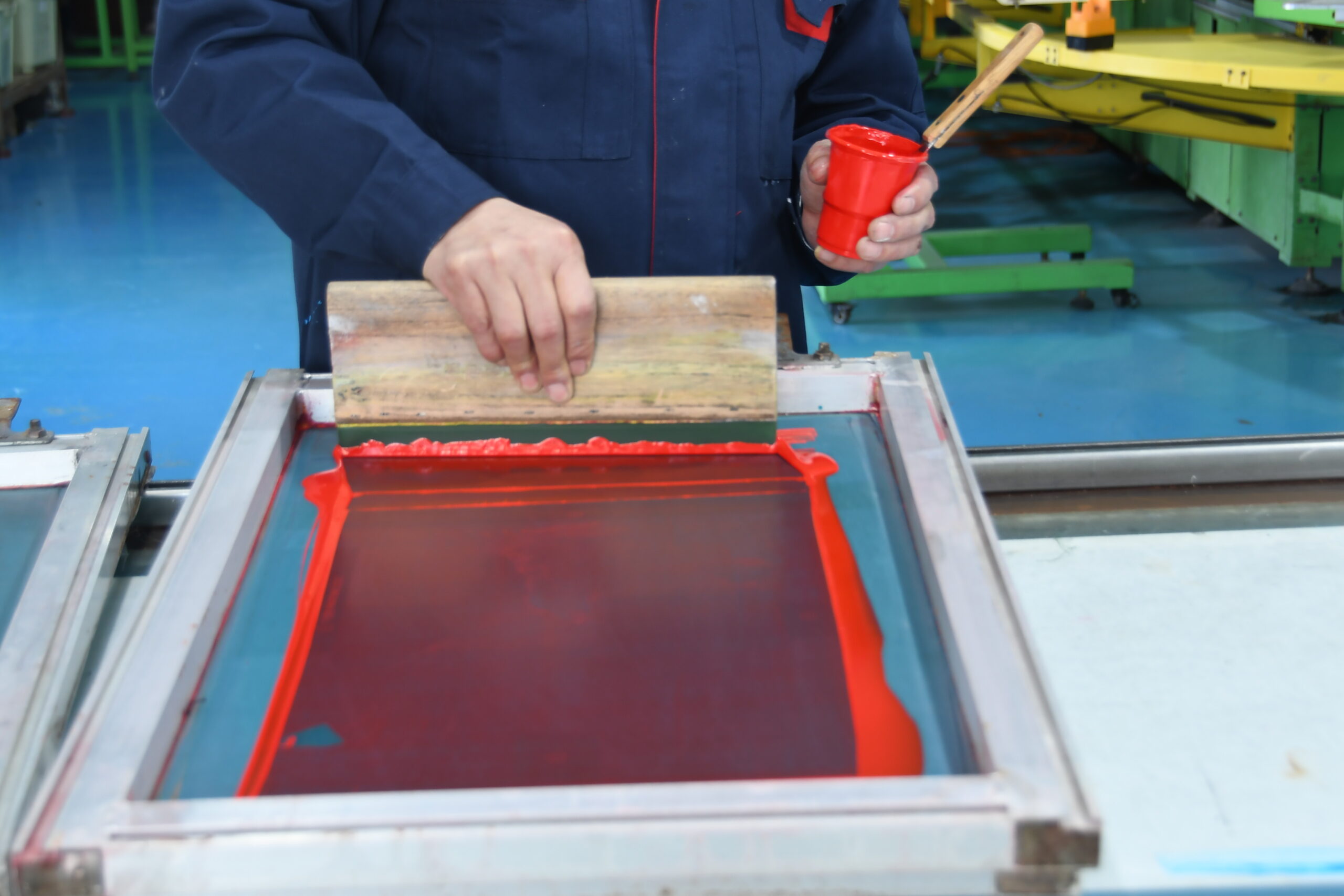

- Squeegee Selection for glitter and shimmer inks is essential for best results, so discover the right tools.: Helps in even ink deposit.

- UV-resistant Plastisol: Use for outdoor prints.

Here is a checklist for your ink:

- Plastisol:

- High opacity inks are essential for screenprinting vibrant designs.

- Soft-hand finish is essential for a pleasant texture.

- Industrial durability

- Glitter:

- High glitter particle density

- Micro glitter or chunky glitter can be formulated into your designs for added texture.

- Fine mixing techniques

The ink you choose shows many words like heat-cure plastisol, screen mesh count, and bulk ink purchasing. They are key in quality and performance.

4. Top 5 Applications for Plastisol & Glitter Inks

These are the best ways to use the inks to take your projects to the next level:

- Apparel:

- T-Shirts

- Hoodies can be printed with graphic designs that are long-lasting.

- Leggings printed with our specialty inks can showcase the ultra designs you desire.

- Promotional Products:

- Bags made with phosphorescent inks can glow in the dark, creating amazing outcomes for the brand.

- Caps

- Custom merchandise

- Event Merchandise:

- Weddings

- Parties often require vibrant textile designs, so click to discover the best colors and techniques.

- Special editions

- Industrial Printing:

- Whether you’re looking for workwear or casual wear, we have it all.

- Athletic gear

- Safety vests are essential for job sites and events, providing visibility and protection.

- Creative Fashion:

- Unique designs

- Holographic effects

- Reflective finishes

These uses meet the market needs. They work with a client base that demands high-quality results. custom glitter blends, foil adhesive inks, and puff ink additives. You may see terms like metallic silver or phosphorescent when browsing through specialty inks. Glitter adhesive bases and specialty screen printing inks are essential for creating eye-catching designs that are consistent in quality. and print-on-dark fabrics too.

5. Troubleshooting Common Ink Issues

Sometimes, you face problems when you print. Here are some ideas to fix them.

Common Issues with Plastisol Inks:

- Poor adhesion:

- Use clean substrates that activate the vibrant colors of our specially formulated inks.

- Use adhesion promoters.

- Ink curing issues can be resolved by maintaining the right temperature during screenprinting.:

- Check your curing temperature.

Common Issues with Glitter Inks:

- Clogged screens:

- Use a proper screen mesh count.

- Mix the ink well.

- Glitter particle loss:

- Use the right glitter density.

Pro Tips:

- You can dilute inks The shirt design will shine with a touch of glitter ink. curable reducer can help achieve unlimited viscosity adjustments in your inks. for fine details.

- Ensure you have the right inks for your job to achieve the best results. screen emulsion types.

- Pay attention to ink shelf life and ink waste reduction tips.

6. Where to Buy Quality Plastisol & Glitter Inks

You can buy high-quality inks from trusted suppliers. Here are some tips to help you formulate the perfect screen printing ink mixture:

- Top Suppliers (2024):

- PolyOne Corporation (Wilflex)

- Rutland Plastic Materials offers a variety of phosphorescent inks that glow in the dark.

- International Coatings Co.

- FN Ink specializes in high-quality graphic inks for professional screen printing.

- Nazdar SourceOne

- Retailers: select from our eco-friendly specialty ink supply for screen printing that is exposed to water.

- ScreenPrinting.com (Ryonet)

- Matsui International

- Speedball Art Products

- Online B2B Platforms:

- Thomasnet is a great resource to order specialty inks and materials.

- Join the Alibaba Supplier Network to connect with customer-focused brands.

Cost-Saving Tips:

- Bulk ink purchasing can give you discounts.

- OEM plastisol formulas from Avient specialty inks’ catalog are often utilized in various applications. can assure quality.

- Ask for glow-in-the-dark options. We offer free samples/testing kits to help you discover the best options for your needs, ensuring you are grateful for the choices available..

For more info on inks, check our guides on textile printing. glow in the dark plastisol ink, Reflective plastisol ink is a job well done for enhancing visibility., and anti-migration plastisol ink is ideal for textile printing..

7. Eco-Friendly Alternatives

We now look at eco-friendly ink choices:

- PVC-free Glitter Inks:

- These are water-based or hybrid formulas.

- They meet OEKO-TEX Certification and Eco-Passport by Hohenstein These standards expose the quality of your prints.

- Low-Odor Plastisol Inks:

- They use HSA (high-solids acrylate) inks are a popular choice among customers looking for high-quality graphic solutions..

- They are safe for you and the environment.

Eco ink is key in today’s market for brands aiming for sustainability and unlocking new customer bases. Many printers now use eco-friendly plastisol and sustainable ink solutions. These inks help in regulatory compliance and are seen in print-on-dark fabrics designs.

8. Data and Case Studies

Below is a table with key data and case studies:

| Category | Data/Case Study | Key Insight |

|---|---|---|

| Market Growth | Global screen printing ink market: \$8.2B in 2023. | Plastisol dominates 62% share. |

| Plastisol Adoption | 85% Medium-to-large printers use plastisol inks that pop with high opacity. | They use it for bold logos and high volume printing. |

| Glitter Ink Demand is rising in textile applications. | 18% Of specialty ink sales, Avient specialty inks’ products are among the most sought after. Micro-glitter inks offer a crystalina effect that adds sparkle to your designs. is the fastest-growing type. | Used in fashion and event merchandise. |

| Eco-Trends | 35% of printers use PVC-free glitter inks now. | EU REACH rules push eco-friendly options. |

| Performance Metrics | Cure temps for glitter and shimmer inks can vary, so be sure to click for more details. 300-330°F for plastisol, 320-340°F for glitter inks. | Tight temp control is key. |

| Washability is essential for customer service satisfaction. | Plastisol: 50+ washes; Glitter inks: 25 washes. | Plastisol is best for durable prints. |

| Cost Comparison of ic specialty ink versus traditional inks. | Glitter inks cost 20-30% more Dye inks are often preferred over plastisol inks for their amazing outcomes. | Higher cost due to glitter density. |

| Case Study | EcoPrint Solutions Had amazing outcomes with our dye inks in past projects. 40% less waste using PVC-free hybrid glitter inks. | Hybrid formulas help reduce clogs and improve quality. |

| Regional Trends | Asia-Pacific is 48% of global plastisol consumption. | Big in China is known for its innovative dye techniques in screenprinting. and India for bulk purchasing. |

| Troubleshooting Stats | 60% of screen printers prefer using special effects inks. of glitter issues come from screen mesh issues (110-156 mesh suggested). | Correct screen mesh count avoids clogs. |

| Certifications | 78% of buyers require OEKO-TEX or Eco-Passport certifications. | Certifications are very important for customer service and product quality assurance. compliance. |

| Durability Test: Unlock the potential of your prints with our rigorous testing methods. | Plastisol inks do 40% better than water-based inks in abrasion tests. | Use for workwear and High-traffic designs that expose vibrant colors are best achieved with our screenprinting techniques.. |

| Customization Trend | 45% of suppliers now offer metallic and glitter and shimmer inks, including options to unlock unique effects. on-demand ink mixing (Pantone matches). | This is good for screen printers looking to create special effects. limited-edition runs of specialty screen prints.. |

| Case Study | Screened Gear Inc. saw a There was a 22% sales increase after the brand introduced eco-friendly shirts. with holographic glitter inks. | Glitter inks boost value for gifts and apparel. |

9. More Tips and Tricks

Here are more easy tips to help you:

- Use the Right Tools: Use screen printing equipment and silk screen supplies. Great tools lead to great prints.

- Learn New Skills: Watch our tutorial on how to select the best glitter for your projects. screen printing tutorials to see ink layering techniques. Then, try ink jet-to-screen conversions.

- Test Your Inks: Use specialty ink samples, including shimmer and glitter options.. Test for colorfastness testing and wash durability is crucial for prints that can withstand over eight washes..

- Fix Problems Fast: If you face challenges with your prints, click here for troubleshooting tips. ink compatibility issues, check the avient specialty inks for unique finishes. Always check the ink safety data sheets for our specialty screen printing inks.. You can also join Join the specialty ink forums to learn more about textile printing. or attend to discover the next level of printing techniques. screen printing workshops.

- Cost Savings: Use bulk ink purchasing and check B2B ink marketplaces for the best deals.

- Stay Safe: Follow our guidelines to unlock the full potential of your screen printing inks. regulatory compliance guides and use flame retardant standards are crucial when using special effects inks. if needed. Read ink safety data sheets to know more.

These tips help you print on graphic standards and maintain consistent quality. We can print on various substrates, including forty standard colors and direct-printing options. with vibrant color retention. They even work with screen printers who specialize in metallic silver and special effects. manual vs. automatic presses.

10. Final Thoughts

Printing with specialty inks is fun and full of art. Whether you use eco-friendly options or traditional inks, the quality will unlock your designs’ potential. plastisol inks or glitter inks, remember these points:

- Choose the Right Ink: Look at the cost comparison for specialty screen inks and their amazing outcomes to discover the best options. opacity, curing temperature, and adhesion promoters.

- Match Application to Ink Type: metallic or glitter and shimmer inks. Use plastisol inks for strong, vibrant prints. Use glitter inks for sparkle and shine, explore our infinite fx range.

- Troubleshoot and Learn about specialty screen printing inks. Fix screen mesh count Address issues and follow the guidelines for consistent results in your printing projects. ink mixing techniques can enhance the use of avient specialty inks.. Use internal screen reclaiming chemicals when needed, especially when using amazing inks.

- Buy from Trusted Sources: It’s a job well done when you choose trusted suppliers. Learn about OEM plastisol formulas and ask for free samples/testing kits. Trusted names like FN Ink, Nazdar SourceOne, and Ryonet (ScreenPrinting.com) can help you get quality inks, including avient specialty inks.

For more ideas on new ink types, see our guides on Our glow-in-the-dark blue plastisol ink is perfect for specialty projects, offering the possibility of unique designs., and glow in the dark green plastisol ink with shimmer effects, including 15 direct-printing options..

11. Summary Table of Ink Characteristics

Below is one more table for your quick view of the dye options available.

| Ink Type | Key Traits include the ability to pop under various lighting conditions. | Best For | Notes |

|---|---|---|---|

| Plastisol Inks | Our PVC-based, heat-cure inks provide high opacity and are specially designed for durability. | Bold logos, workwear, sports gear | Cures at 300-330°F |

| Glitter Inks | Shiny, with micro or chunky glitter, more costly | Event apparel, fashion, party wear | Requires careful attention to detail to achieve amazing outcomes. 320-340°F Curing requires a careful mix of discharge and glow-in-the-dark inks. |

12. Extra Resources

Learn more on specialty screen printing inks. screen printing ink Order from these sources to find the best specialty inks for your projects.

- Check our specialty ink Visit our page for more details on formulating the perfect shirt.

- Visit the Avient specialty inks’ website to explore their extensive product range. reflective plastisol ink page if you need guided help.

- Explore our selection of textures available for your printing needs. anti-migation plastisol ink Visit our page for quality information on screenprinting techniques.

13. In Conclusion

We hope you learn a lot about specialty ink supply Today, our brand offers a variety of shirt options. The world of screen printing inks is bright! From custom glitter blends to Our UV-resistant plastisol is available in an infinite fx range of colors, including forty standard colors. and Eco-friendly alternatives are now a possibility in many printing jobs., there is something for everyone.

Keep in mind:

- Use ink curing temperature Our guides help customers navigate the screenprinting process effectively, ensuring a consistent experience.

- Follow squeegee selection and screen mesh count rules.

- Check compliance certifications for a safe print.

Enjoy your journey in the art of screen printing. With these simple tips, you can make quality prints and shine with Here are some glitter ink application tips to achieve amazing outcomes. and plastosol solutions. Let your creativity soar!