If you’ve ever seen a “wow” shirt with blinding metallics, dramatic shimmers, or a glowing-in-the-dark graphic and wondered how they did it, you’re about to enter the world of specialty ink and plastisol ink. Screen printing isn’t just about getting an image onto fabric—it’s about transforming garments into wearable art that grabs attention, energizes your brand, and keeps clients coming back for more. This guide explains the magic of specialty screen printing inks, helps you navigate an unlimited supply of effects, and shows you how to select and order the right products to deliver amazing outcomes for every customer. Whether you’re a screen printer, designer, or apparel brand, there’s a treasure trove of specialty ink knowledge ahead—don’t miss your ticket to next-level creativity!

Article Outline

1. What Is Specialty Ink? Exploring the Possibilities for Screen Printing

2. Why Use Plastisol Ink in Specialty Screen Printing?

3. How Do Metallic and Glitter Inks Transform Apparel?

4. The Magic of Shimmer and Crystalina Effects

5. What Sets Glow-in-the-Dark and Phosphorescent Inks Apart?

6. How Can You Use Foil and Reflective for Eye-Catching Designs?

7. Understanding Discharge, Water-Based, and Additive Techniques

8. Choosing the Right Specialty Screen Printing Ink for Your Product

9. Tips for Screen Printers: Mesh, Technical Insight, and Consistency

10. Ordering, Supplying, and Discovering Amazing Inks for Your Cart

1. What Is Specialty Ink? Exploring the Possibilities for Screen Printing

Specialty ink is the secret ingredient that takes a standard print and turns it into something truly unique. Unlike basic inks, specialty ink encompasses a range of ink types—glitter and shimmer inks, glow-in-the-dark, metallic, reflective, and more—that add special effects to textiles and apparel. These inks allow screen printers to achieve vibrant colors, raised textures, or sparkling finishes that mesmerize the eye and leave a lasting impression on anyone who sees or touches the shirt.

Think of specialty screen printing inks as your creative arsenal: whether you want to add a metallic silver gleam, a soft puff effect, or an ultra-bright color that pops under blacklight, there’s a specialty ink or additive designed for that specific job. Using these inks, you can move beyond ordinary graphics and unlock a world of possibility. You’ll stand out—not just as a printer, but as an artist capable of turning ideas into garments with true “wow” factor.

Specialty inks often require special application, mesh choices, and technical know-how, but with the right product and preparation, any screen printer can harness the power of these amazing inks for their brand and their clients. So, if you want consistency, innovation, and grateful customers, specialty ink is your go-to supply for next-level creativity.

2. Why Use Plastisol Ink in Specialty Screen Printing?

Plastisol ink has long been the staple of screen printing, but its versatility only shines brighter when used as a foundation for specialty effects. Plastisol is a PVC-based ink that sits on top of the fabric rather than soaking in, delivering bold, vibrant colors that make graphics pop while offering incredible durability for busy apparel.

The unique nature of plastisol makes it a perfect carrier for specialty screen effects—additives like glitter, shimmer, or metallic flakes can be mixed in seamlessly, creating anything from a soft pearlescent sheen to a dramatic sparkle. Because plastisol ink cures at relatively low temperatures, it helps maintain fabric integrity and ensures printed effects are both durable and consistent wash after wash.

Moreover, plastisol isn’t picky about substrates. Whether you’re working on cotton, blends, or synthetics, it adheres beautifully and keeps its shine. So, if you’re aiming for glitter inks, glow in the dark prints, or shimmer specialties, plastisol is your best friend for making sure your client’s graphics look sharp and professional.

3. How Do Metallic and Glitter Inks Transform Apparel?

Metallic and glitter inks are like jewelry for your prints—they catch the light, add intrigue, and turn ordinary apparel into statement pieces. Metallic inks often feature aluminum or mica flakes, producing an authentic metallic silver or gold effect that reflects dramatically in any lighting. Glitter inks take things a step further with chunkier, specially formulated particles for a bold, eye-catching finish.

When screen printers want to create a bright, shiny, and durable effect, metallic is often the ink of choice. With proper application and mesh selection, metallic inks can deliver crisp detail in logos, text, or full-graphic designs. For the “showstopper” look, combine glitter and shimmer inks for that crystalina sparkle that dances with every move.

Both metallic and glitter screen printing inks are available as readymade products or as additives you blend with standard plastisol ink to dial in the exact level of pizzazz you want. By using avient specialty inks or wilflex for metallics and glitters, you’re assured of consistent results and can offer your customers innovative, one-of-a-kind outcomes.

4. The Magic of Shimmer and Crystalina Effects

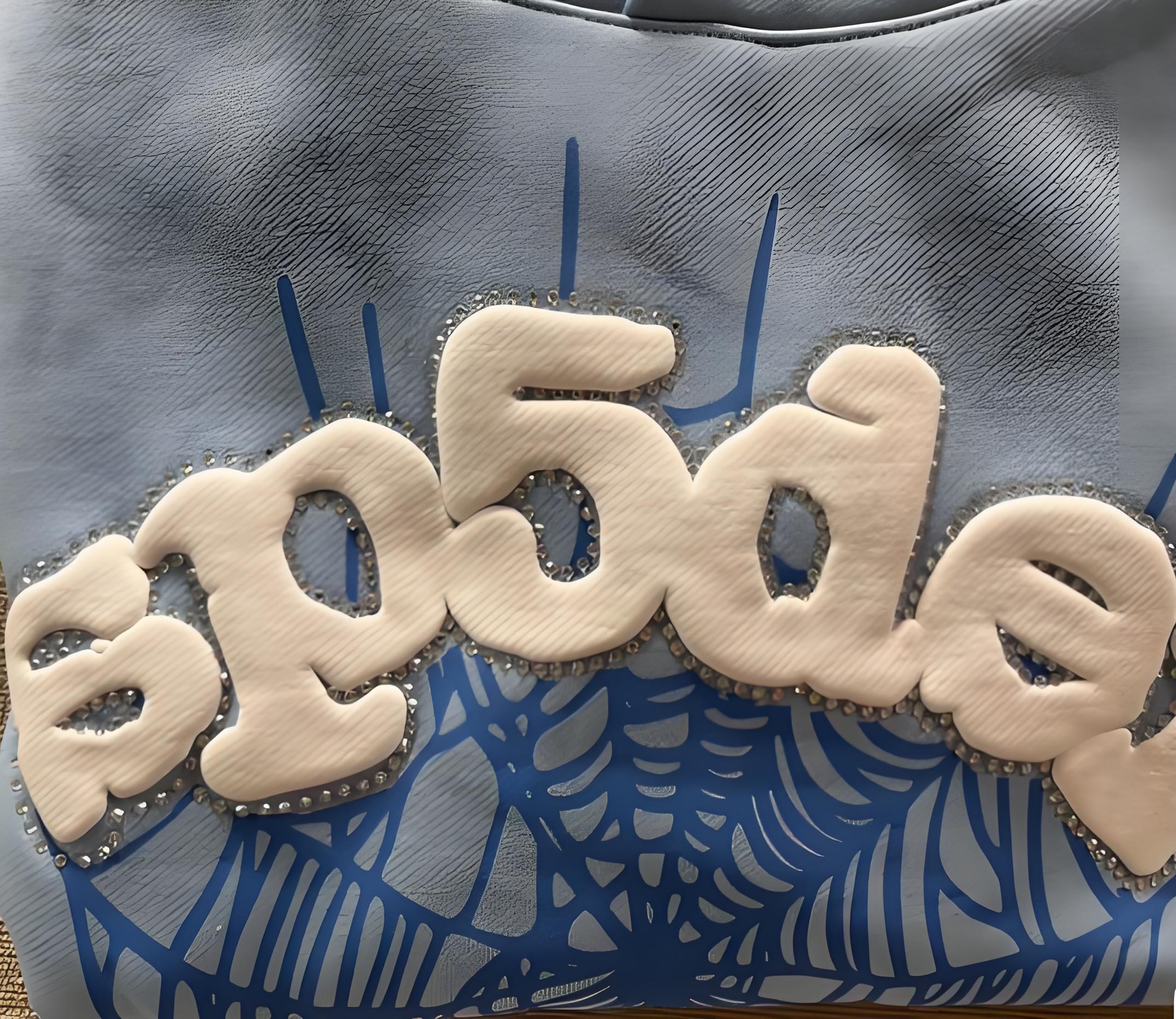

Shimmer and crystalina are all about adding dynamic, shifting highlights to your print. Unlike heavy glitter, shimmer inks have a subtler, more sophisticated luster. Specially formulated mica-based pigments catch and toss light in multiple directions, turning a flat graphic into something almost three-dimensional.

Crystalina ink, by contrast, is loaded with clear or iridescent particles that refract light for bright, multi-hued flashes. This effect is perfect for apparel brands seeking something unique, whether it’s a promotional shirt or a limited-edition run.

Screen printers working with shimmer and crystalina can activate their designs using different mesh counts and application techniques, making every print feel premium and tactile. If you want your next job to reach the next level of creativity, don’t overlook these amazing inks—they unlock the possibility for texture, dimension, and that signature “pop” on fabric.

5. What Sets Glow-in-the-Dark and Phosphorescent Inks Apart?

So, what’s the secret behind those graphics that light up at midnight parties? Glow-in-the-dark and phosphorescent inks are specially formulated screen printing inks that absorb light energy and release it in darkness. These inks are transformative for custom apparel, turning ordinary prints into eye-catching features after dark.

Phosphorescent pigments are the additive that gives glow-in-the-dark ink its magic. Once activated by light, they emit a cool glow when exposed to darkness. Whether you’re printing on shirts for a concert, sports event, or promotional use, these specialty screen inks add value and excitement for your client.

What’s more, you can use phosphorescent in combination with other specialty inks—think glitter, metallic, or even discharge—to layer effects and achieve prints that truly stand out in every setting. With new advancements in the supply of glow and phosphorescent inks, the effects last longer and glow brighter than ever before.

6. How Can You Use Foil and Reflective for Eye-Catching Designs?

Adding foil to your screenprints is like wrapping your graphics in gold—literally. Foil printing requires a special adhesive ink printed on fabric, followed by the application of metallic foil sheets that adhere and peel back to leave a shiny, reflective surface. The results can be downright dazzling, especially for brands that want to project a bold, premium image.

Reflective inks, on the other hand, contain microscopic glass beads that bounce light, making designs visible—even in low light conditions. These specialty inks are favored for safety apparel, sportswear, or any application where both style and functionality are key.

Applying foil or reflective specialty ink requires technical skill and the right mesh and substrate choices. But the payoff is ultra-unique apparel with high visual impact and next-level appeal for your brand and customer alike.

7. Understanding Discharge, Water-Based, and Additive Techniques

Beyond plastisol and glitter, specialty ink techniques like discharge and water-based printing let you get even more creative with fabric. Discharge ink removes (or “discharges”) the dye in the textile and replaces it with new color—or leaves a soft, natural feel where the graphic should be. This method is perfect for achieving highly detailed prints while keeping garments comfortable to wear.

Water-based specialty inks are gaining popularity for their eco-friendly formulation and soft hand. They soak into the fabric, leaving prints bright and breathable. Additives can be used with both discharge and water-based inks to create shimmer, puff, or even ultra-matte effects—formulate your own signature look with just a single click in your supply cart.

All of these specialty screen printing methods open up unlimited creative possibilities and help you align your product offerings with market trends and client demands.

8. Choosing the Right Specialty Screen Printing Ink for Your Product

Selecting the right ink isn’t just about color. Consider the application: Is it for vibrant promotional shirts, durable teamwear, or custom boutique apparel? Evaluate what kind of effect you want—metallic, shimmer, glitter, glow, or reflective. The product substrate (fabric type), mesh, curing profile, and even environmental concerns may all dictate which specialty ink works best.

For textile screen printers wanting consistent, amazing outcomes, partnering with reliable supply brands like avient specialty inks’ Wilflex or Infinite FX Range ensures technical support, a wide range of colors (including forty standard and 15 direct-printing shades), and the ability to order what you need for every job at a click.

Don’t underestimate the power of customer service—getting advice, insights, and practical tips will help you select specialty inks that deliver premium results and grateful clients.

9. Tips for Screen Printers: Mesh, Technical Insight, and Consistency

Achieving stellar prints with specialty ink isn’t just about what you use, but how you use it. Mesh choice is critical: a lower mesh count allows larger glitter or metallic flakes through, while a higher mesh gives crisp detail for shimmer or discharge inks. Always test on the intended substrate to ensure optimum effect and durability.

Technical insight from others in the industry—your supply partners or in-house screen printers—can help you troubleshoot problems before they start. Factors like curing temperature, humidity, and even how you store specialty screen printing inks all impact performance and consistency.

Whether you’re working on a high-volume order or a one-off custom print, maintaining a grateful and curious approach will keep your jobs running smoothly and delight your clients with every shipment.

10. Ordering, Supplying, and Discovering Amazing Inks for Your Cart

Once you’re ready to try specialty ink, the process is simple: select the effect you want, pick your base (like plastisol, water-based, or discharge), and add-on any necessary additives for shimmer or glow. Place your order with a trusted supply brand, load up your cart, and prepare to unlock unlimited creative potential.

Leading supply houses now offer incredible online tools and customer service. Explore new products, discover technical data, and even watch demo videos before you buy. Whether you want ultra-bright glitter inks or subtle metallic silver, there’s an effect waiting for you.

And don’t forget—keeping up with innovative specialty screen products means you’ll always have eye-catching designs to offer your clients, making your screenprinting business the go-to for amazing outcomes.

Summary: Key Takeaways for Achieving Next-Level Prints with Specialty Ink

- Specialty ink lets you create vibrant, unique, and textured effects, unlocking almost unlimited creative potential for screen printing.

- Plastisol ink remains the go-to base for glitter, metallic, shimmer, and many additive effects due to its durability, versatility, and compatibility with a wide range of textiles and substrates.

- Metallic and glitter inks add stunning shine and sparkle—perfect for eye-catching graphics and premium apparel.

- Shimmer (including crystalina) and phosphorescent (glow-in-the-dark) inks provide next-level effects that wow in both daylight and at night.

- Foil and reflective inks deliver maximum visual impact, pairing style with function for both fashion and safety applications.

- Discharge and water-based inks offer eco-friendly, soft-touch, and highly detailed printing options, especially when used with the right additives.

- Choosing the right specialty ink requires careful consideration of substrate, intended effect, mesh, and finished garment use.

- Screen printer technique and technical insight are as critical as the ink itself for consistent and durable amazing outcomes.

- Reliable supply partners and brands (like avient specialty inks and wilflex) provide technical support, consistent quality, and endless creative options.

- Staying curious, exploring new products, and continually learning will keep your screen printing business at the leading edge, delivering results that delight every client—every time.

Happy printing, and may your journey with specialty ink be ultra-inspiring, innovative, and full of amazing outcomes!