Key Takeaway: Metallic Silver Plastisol Inks for Screen Printing

- Metallic silver plastisol inks give screen printed garments the shiniest and most professional shine.

- Achieving extremely high opacity relies on mesh materials, top-quality inks and the right substrate.

- The key to achieving this is testing the print, adhering to the manufacturer’s settings, and performing wash tests to ensure durability.

- International Coatings’ No. 96 Metallic Silver excels in insurance, adhesion and ready-to-use convenience.

- Metallic inks use lower mesh counts (86-110), and stencils and emulsions are designed for these thicker formulations.

- For thermal transfers, choose fast or low-treat stencil inks and always focus on adhesion and blending.

- Troubleshoot with the help of display mesh, stencil preparation, curing faults and use of appropriate additives.

- Stock up on key display screen printing materials, including mesh, emulsions, squeegees and unique additives for top-notch results.

- Frequently wash test and investigate prints – negative fusion or opacity can become apparent after washing.

- Mastering these recommendations will help you confidently install steel silver inks for great, long-lasting prints that your customers will love.

With this realistic training, you’ll turn every batch of metallic prints into a real showstopper – one that sets your paintings apart. Start experimenting with your next quart of shimmering silver ink today and bring your designs to life!

Shine On: Mastering Metallic Silver Plastisol Ink for Dazzling Screen Printing Results

Ready to unlock the eye-catching, excessive-effect consequences of metal ink on your display screen printing tasks? This guide demystifies metal silver plastisol ink—from the way to acquire an ideal remedy to maximizing shimmer, opacity, and sturdiness. Whether you’re experimenting with International Coatings 96 Metallic Silver, evaluating options in sizes from 8oz to quart, or troubleshooting your prints, you’ll discover practical recommendation and pro tips. If you need to make your garments gleam with expert satisfactory that lasts, this is the thing you may’t miss. Let’s make your display screen printing honestly shine!

Article Outline

- What Makes Metallic Silver Plastisol Ink So Appealing?

- How Does Metallic Silver Ink Differ from Standard Plastisol Ink?

- What Is the Best Way to Achieve Excellent Opacity with Metallic Inks?

- Tips for Proper Curing: How to Cure Metallic Silver Plastisol Ink Correctly

- What’s Special About International Coatings 96 Metallic Silver?

- Choosing Screen Mesh Count, Stencil, and Emulsion for Metallic Inks

- Metallic Inks and Adhesion: What You Need to Know

- Can You Use Metallic Silver Plastisol Ink for Heat Transfers?

- How to Troubleshoot Common Challenges: Print Cracks, Poor Opacity, and More

- Essential Screen Printing Supplies and Additives for Metallic Silver Effects

1. What Makes Metallic Silver Plastisol Ink So Appealing?

When you want your display screen printing to face out, steel silver plastisol ink offers a outstanding, shimmering finish that preferred inks clearly can’t in shape. The precise appearance of metal ink brings vibrancy and a sleek shine to any garment—making designs pop, specifically on darkish garments. This shimmer impact is ideal for unique occasion shirts, athletic put on, and fashion prints wherein you want to grab attention.

But the appeal goes past simply one look. With the right plastisol ink for display screen printing, you unencumber now not simplest awesome steel sheen but also sturdiness and flexibility. That’s important for some thing meant to remaining thru repeated wash tests and real-global put on.

For print shops and DIY printers alike, mastering metallic silver ink provides a versatile, high-value approach in your skill set. Brands like International Coatings 96 Metallic Silver have set industry standards, making it viable to get incredible results right out of the field—no complicated mixing required.

2.How Does Metallic Silver Ink Differ from Standard Plastisol Ink?

The mystery to metallic silver plastisol ink’s sparkle lies in its especially formulated metal pigments. These mirror light, developing a reflect-like or pearlescent floor that traditional plastisol ink can’t acquire. While trendy plastisols are designed to supply vibrant colorations and amazing opacity, metal inks carry a brand new size—literally.

However, those steel flakes mean that steel silver ink behaves a piece in another way throughout printing. For instance, the larger pigment debris can affect things like mesh selection and ink glide, and may additionally require changes in squeegee pressure and perspective.

Another key difference: metal inks, in particular those like ninety six Metallic Silver or rapid remedy plastisol ink traces, frequently need special attention in the course of the therapy segment to make certain whole fusion without sizzling the steel additives. Balancing these issues is crucial if you need your prints to each shine and closing after multiple wash cycles.

3.What Is the Best Way to Achieve Excellent Opacity with Metallic Inks?

Getting excellent opacity—that strong, non-streaky appearance—is a pinnacle issue whilst operating with steel silver plastisol ink. Opacity ensures that your prints appearance rich and reflective even on the darkest garment shades, like black or army.

Start through deciding on a high-opacity ink like International Coatings ninety six Metallic Silver plastisol ink. Many expert printers endorse the usage of a base white beneath the metallic layer for even more pop, particularly on dark garments. This extra step prevents the ink from soaking into the material and dropping its metallic look.

Mesh count number is every other essential aspect: the usage of a lower mesh (86–one hundred ten) gives the ones metal flakes room to skip via while maintaining thickness and brightness. The right displays, paired with a strong emulsion and careful stencil training, will guide your quest for most desirable insurance and opacity.

4. Tips for Proper Curing: How to Cure Metallic Silver Plastisol Ink Correctly

Nailing the treatment is crucial; even the first-rate steel silver plastisol ink can peel or crack if now not nicely fused. Complete fusion occurs while the plastisol base and the metallic pigments bond thoroughly for your garment fibers throughout heating.

Typically, metal silver inks require a dwell time of forty five–60 seconds at a temperature of 320°F to 330°F for full remedy, but it’s always great to check the producer’s recommendations for distinctiveness inks like 96 Metallic Silver. Use a conveyor dryer for regular consequences, but a spot therapy unit or dryer can suffice for smaller runs.

To absolutely test the remedy, an excellent practice is the wash check to make sure sturdiness—in case your print cracks or the print will show deterioration, it’s again to the drafting board. Remember: metal pigments can mirror warmness, so every so often you could want a slightly longer live time or lower the heat to shield sensitive fabric.

5. What’s Special About International Coatings ninety six Metallic Silver?

International Coatings 96 Metallic Silver is a extensively reputable desire for execs and beginners alike. Unlike some steel products, this ink comes geared up to use—print it proper out of the box for instant shimmer.

What sets 96 Metallic Silver plastisol ink aside is its mixture of excellent opacity, robust adhesion, and short treatment instances. Available inside the famous 8oz, 16oz, 32oz, and quart sizes, it’s smooth to find the amount you need for any assignment scale.

This ink is likewise recognised for its non-phthalate method, making it a safer preference for each printers and cease-users. High-high-quality insurance, vivid shine, and reliable consequences make International Coatings 96 Metallic Silver a go-to for any save in search of that more dazzle in their lineup.

6.Choosing Screen Mesh Count, Stencil, and Emulsion for Metallic Inks

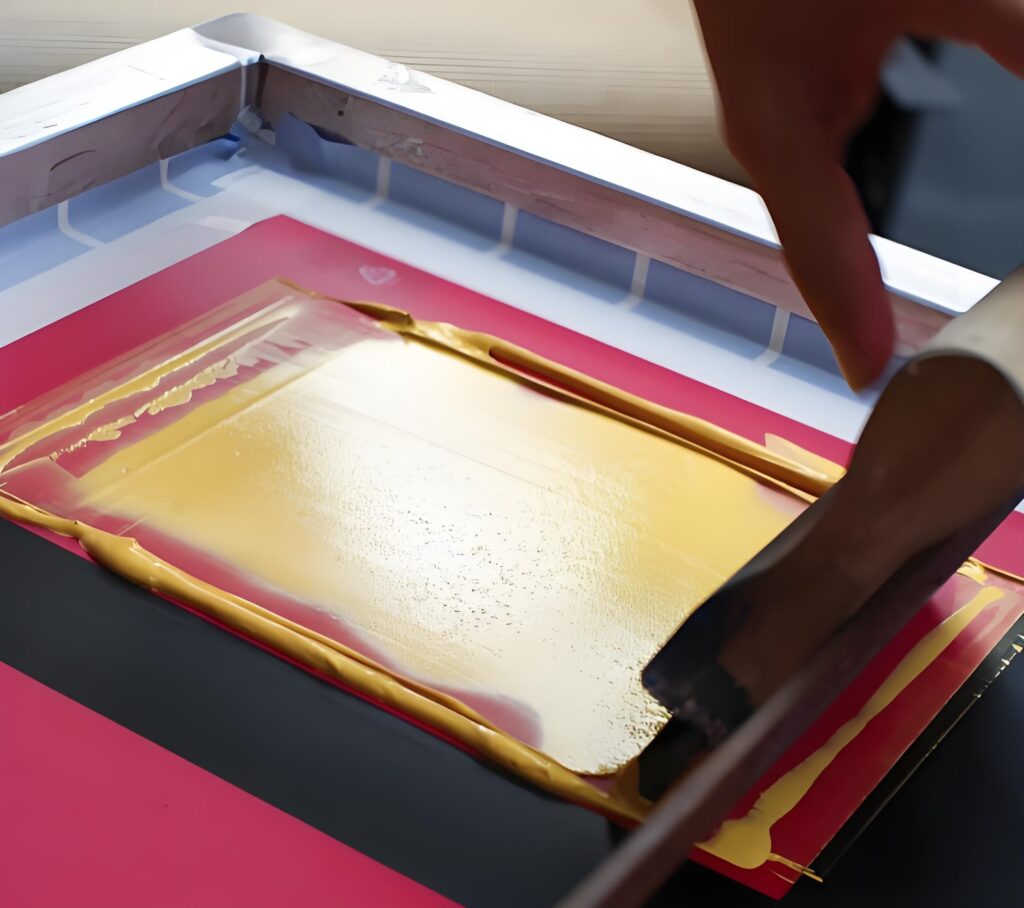

Selecting the proper mesh remember is important for maximizing the performance of metal silver ink. A mesh remember within the 86–a hundred and ten range allows the ones larger metal flakes to skip thru the display and settle flippantly on the garment surface, enhancing shimmer and opacity.

Pair this mesh with the right emulsion and properly-prepared stencil. Since steel inks are thicker, a durable emulsion enables keep sharp layout element and minimizes display screen breakdown. When coating stencils, purpose for a medium thickness to aid each ink go with the flow and part definition.

Don’t skimp on screen prep: completely test published displays will catch issues before you run a large batch. If you word blockages or choppy prints, take a look at your monitors and stencils first, as metal pigments can clog finer meshes extra quick than regular based totally ink.

7. Metallic Inks and Adhesion: What You Need to Know

Strong adhesion manner your metal prints don’t simply appearance correct—they closing. The secret lies in right fusion for the duration of curing, accurate ink thickness, and using helping products if vital.

Some textiles, particularly cotton and polyester blends, require a low bleed ink or low bleed additive to prevent dye migration from the garment into the ink, which can stupid your shimmer and shine. Using a appropriate plastisol ink by using display print direct or an additive designed for stronger adhesion could make all of the distinction.

Remember, attaining consistent adhesion also involves correct squeegee method. The squeegee need to be corporation but bendy enough to deposit a layer of ink that helps complete insurance and bonding with out immoderate construct-up.

8. Can You Use Metallic Silver Plastisol Ink for Heat Transfers?

Heat transfers with metallic silver ink are viable and increasingly famous. The benefit right here is flexibility in design placement and manufacturing, permitting complicated or multi-color prints onto specific garments with out a couple of press runs.

To pull this off, you’ll need a low therapy ink or plastisol ink that healing procedures at lower temperatures to avoid scorching the release paper or the garment. Rapid treatment plastisol ink and certain lines of metal silver plastisol ink excel in this area.

Pair your metal hot peel or cold peel transfers with a stable adhesive layer for performance that stands as much as washing and normal put on. Always check your transfer with small batches to make sure proper whole fusion and avoid wasted time or materials.

9.How to Troubleshoot Common Challenges: Print Cracks, Poor Opacity, and More

Even pro printers run into problems with metal silver plastisol ink. The most frequent problem is print cracks—often because of below-cured ink, over-thick deposits, or immoderate stretching of the garment. Use a wash test to make certain your cure is strong; if cracks appear, extend the reside time or growth the dryer temperature slightly.

Poor opacity can also be an issue, mainly on dark fabrics. Upgrading to a excessive-opacity metallic ink, the usage of a base white underlay, or refining your mesh and stencil will generally solve this.

Other frustrations like clogged monitors or ink setting apart on polyester blends frequently trace back to mesh choice or lack of a low bleed additive. Stay vigilant with your spot therapy unit, and continually fully check the cure before a complete production run. And if ink is just too thick, a small quantity of curable reducer can enhance go with the flow without sacrificing adhesion or brightness.

10.Essential Screen Printing Supplies and Additives for Metallic Silver Effects

To get stunning results with metallic silver plastisol ink, stock up on key screen printing supplies like:

- Proper mesh screens (86–110 be counted)

- Durable emulsion for crisp, lengthy-lasting stencils

- Squeegees in more than a few durometers for excellent manipulate

- Conveyor dryers or spot therapy devices for unique, dependable curing

- Additives like curable reducer or low bleed ink for strong point projects

Don’t neglect forte components that may enhance printability or enhance effects. For example, including a touch of base white to steel ink can both enhance opacity and boom insurance on difficult fabric.

With the right supplies reachable, plus a stable understanding of display printing plastisol ink dynamics, your metal paintings will always provoke and endure.