Screen Printing Ink for Fabric Solution

When screen printing ink for fabric, it is critical to choose the right fabric and technique along with the ink to ensure optimal performance. Here are some solutions and suggestions for using screen printing ink for fabric. For customized best ink for silk screen printing solutions and learn more screen press ink expert advice, contact us!

Ink on cotton are a versatile choice for screen printing on cotton fabrics due to their vibrant colors, durability, and ease of use. This guide provides basic steps and tips for getting the best results and considerations when printing with plastic inks.

95%

solve problems

98%

Customer Satisfaction

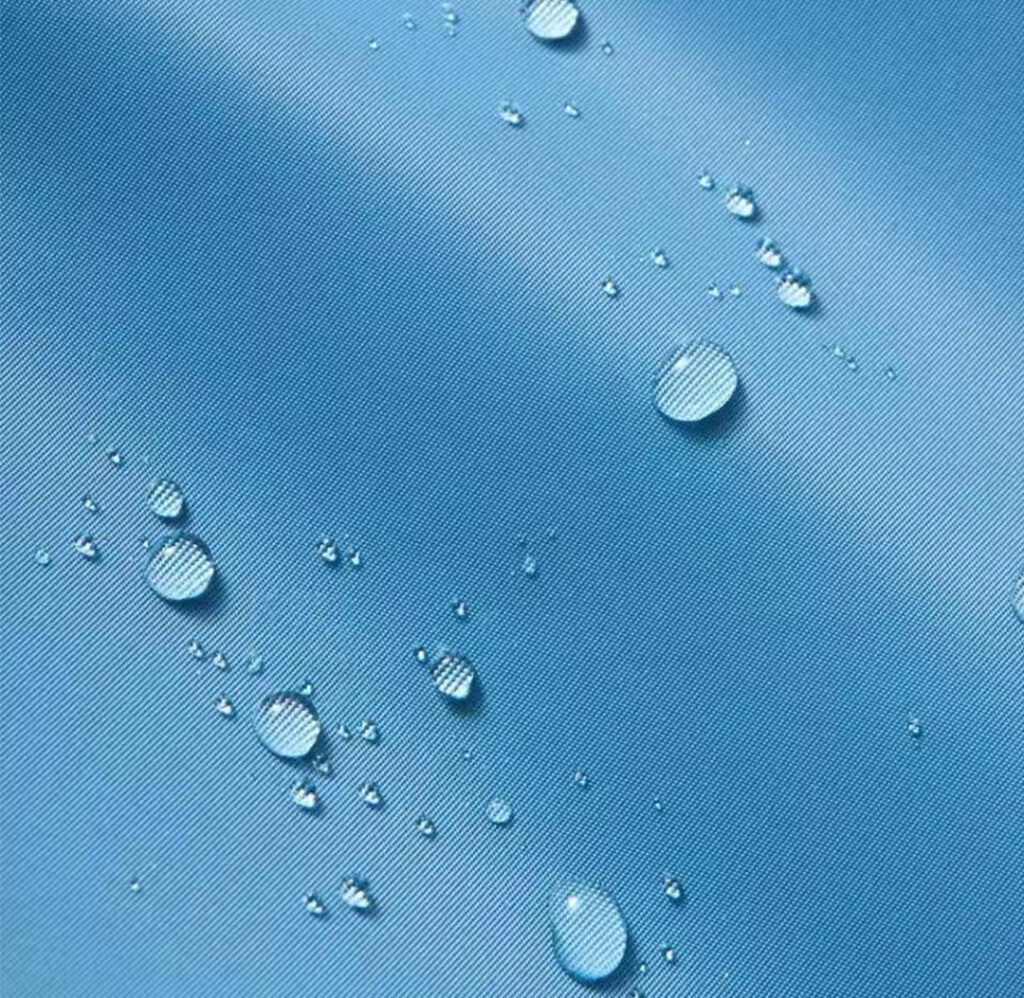

Polyester is a synthetic fabric known for its strength, moisture-wicking properties, and resistance to wrinkles and shrinking.Commonly used in athletic wear, uniforms, and outdoor gear due to its ability to hold color and withstand repeated washings.

95%

solve problems

98%

Customer Satisfaction

Lycra spandex is known for its elasticity, softness, and moisture-wicking capabilities. It typically contains a blend of polyester, nylon, or cotton, enhancing comfort and durability.Widely used in athletic wear, swimwear, and fitted clothing where stretch and recovery are essential.

95%

solve problems

98%

Customer Satisfaction

Nylon Print——Silk Screen Printing Guide

Nylon is known for its strength, elasticity, and moisture-wicking properties. It has a smooth surface, which can enhance print quality.Often used in activewear, jackets, bags, and various outdoor apparel due to its resilience and performance capabilities.

95%

solve problems

98%

Customer Satisfaction

Printing on Poly blends ——Silk Screen Printing Guide

Poly blends are known for their strength, softness, and versatility. The blend ratio can vary, affecting the fabric’s feel and printability.Frequently found in athletic wear, t-shirts, and casual apparel, poly blends are popular for their comfort and performance characteristics.

95%

solve problems

98%

Customer Satisfaction

Silk Screen Printing On Leather——Silk Screen Printing Guide

Different types of leather (e.g., cowhide, lambskin, suede) have varying textures and properties. Smooth leather is generally easier to print on than textured or porous types.Leather is a natural material known for its durability, flexibility, and distinctive appearance, making it ideal for fashion and functional items.

95%

solve problems

98%

Customer Satisfaction

If you have any questions about screen printing ink for fabric, please consult us