Master screen printing emulsion with expert tips on curing, coating, and spotting defects. Ensure flawless prints every time.

1. What Are the Signs of Overexposure in Screen Printing?

Overexposing a screen during the emulsion curing process is a common beginner mistake. Key signs include:

- Brittle stencils that crack during printing.

- Difficulty washing out unexposed emulsion (even after extended rinsing).

- Loss of fine details in the design due to excessive UV hardening.

- Visible “ghosting” around edges where light leaked through the film.

To avoid this, always perform an exposure test using an exposure calculator. Adjust your UV light source’s distance and timing based on emulsion type.

2. What Is Emulsion for Screen Printing?

Screen printing emulsion is a light-sensitive liquid applied to mesh screens to create stencils for ink transfer. It hardens when exposed to UV light, blocking ink in non-design areas while allowing it to pass through open mesh sections.

There are two primary types:

- Dual-Cure Emulsions: Ideal for high-detail jobs; combine diazo and photopolymer for versatility.

- Photopolymer Emulsions: Faster exposure times but less forgiving with overexposure.

For beginners, dual-cure emulsions like Ulano QTX or Chromablue are recommended for their balance of ease and performance.

3. How Many Times Do You Coat Screen With Emulsion?

Most screens require 1-2 coats per side (total 2–4 coats). However, this depends on:

- Mesh Count: Higher mesh (e.g., 230+) needs thinner coats to avoid clogging.

- Emulsion Viscosity: Thicker emulsions may require fewer coats.

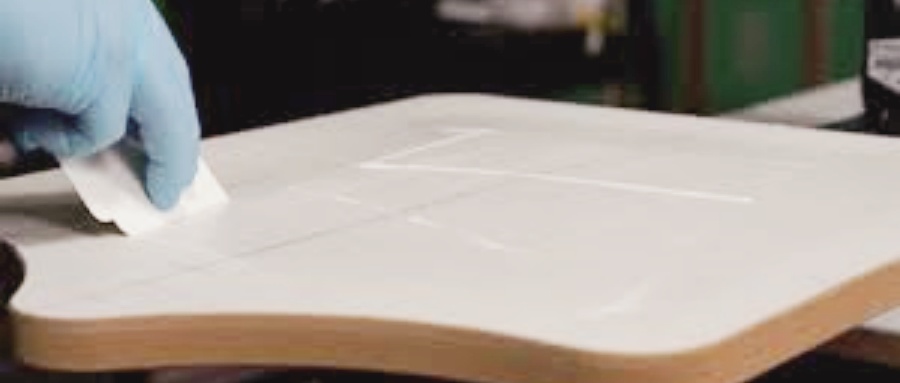

Pro Tip: Use a scoop coater for even application. Hold the screen at a 45° angle and apply emulsion in smooth, upward strokes. Let each coat dry completely (30–60 minutes) before adding the next.

4. How to Tell If Your Emulsion Is Bad?

Expired or degraded screen printing emulsion leads to failed stencils. Watch for these red flags:

- Color Changes: Yellow or brown tints indicate chemical breakdown.

- Lumpy Texture: Proper emulsion should be smooth; clogs signal spoilage.

- Weak Adhesion: Peeling during washout means it’s lost photosensitivity.

- Foul Odor: A sour smell suggests bacterial growth.

Always check expiration dates and store emulsion in a cool, dark place.

5. How Long Does Emulsion Take to Fully Cure?

After coating and drying, emulsion needs UV exposure to cure. Timing varies by type:

- Dual-Cure: 3–8 minutes under a 500W UV light.

- Photopolymer: 1–3 minutes.

Post-exposure, let screens rest for 15–30 minutes to stabilize before washing out.

6. How Long Does Screen Printing Emulsion Last?

Unmixed screen printing emulsion lasts 6–12 months if stored properly. Once mixed with diazo (for dual-cure), use it within 2–3 months.

To extend shelf life:

- Refrigerate unopened containers.

- Avoid contamination (use clean tools).

- Seal containers tightly after use.

7.How to Correct Overexposure in Screen Printing

Once you’ve identified overexposure in your screen, it’s essential to correct it before proceeding with further prints. Here are a few ways to handle overexposed screens:

- Increase Washout Time: If you’re unable to wash out the unexposed emulsion, try using warm water with gentle agitation for an extended period. Be patient, as this will allow the emulsion to soften and loosen from the mesh.

- Re-coat the Screen: If overexposure has compromised the stencil, you might need to reapply emulsion to the screen. After removing the overexposed stencil, clean the mesh thoroughly, then coat again with fresh emulsion.

- Reduce Exposure Time for Next Prints: To avoid the same issue in future prints, reduce the exposure time slightly or lower the distance between the screen and the UV light source during exposure. Conduct test exposures to fine-tune the settings.

8.Troubleshooting Defects in Screen Printing

While mastering emulsion curing is crucial, common printing defects can still occur. Here’s how to troubleshoot them:

- Pinholes: Tiny, round holes in your prints are often caused by contamination on the screen or an improperly coated stencil. Ensure your screen is thoroughly cleaned before coating, and check for dust or debris before exposure.

- Blurry Prints: This can occur if the stencil isn’t properly exposed or cured. If the stencil is too soft or the exposure is insufficient, fine details may wash away or appear blurry. Always perform a test exposure for accuracy.

- Uneven Ink Coverage: This is usually a result of improper emulsion coating or uneven pressure during printing. Check the emulsion application and make sure your screen is clean and well-prepped.

- Maintaining Your Emulsion and Screens

Taking proper care of both your emulsion and screens will help prolong their life and improve print quality. Regularly clean your screens with screen cleaning chemicals to prevent the buildup of ink residue, and store screens upright in a cool, dry place away from direct sunlight.

Properly managed screens and emulsions make a significant difference in the consistency and quality of your prints, so never skip maintenance steps.

Conclusion

Mastering screen printing emulsion ensures crisp, durable prints. From avoiding overexposure to spotting expired emulsion, these tips help streamline your workflow. Always prioritize proper storage, precise coating, and regular testing to maximize your results.