Are you curious approximately how your favourite custom t-shirts and colourful designs come to lifestyles? This article dives deep into the sector of display screen print direct, exploring the display screen printing technique, critical gadget, and the way printers turn your thoughts into beautiful garb. Whether you’re looking to begin a print commercial enterprise, location a custom order, or simply need to understand what makes screen print direct so famous for garb, you’ll locate all the answers right here. Read directly to discover why this guide subjects—now not most effective will it help you apprehend this printing approach, but it’ll additionally assist you are making informed alternatives whilst ordering custom garb, launching a brand new enterprise, or selecting the proper printer and device for targeted, wonderful consequences.

Table of Contents

1. What Is Screen Print Direct and How Does It Work?

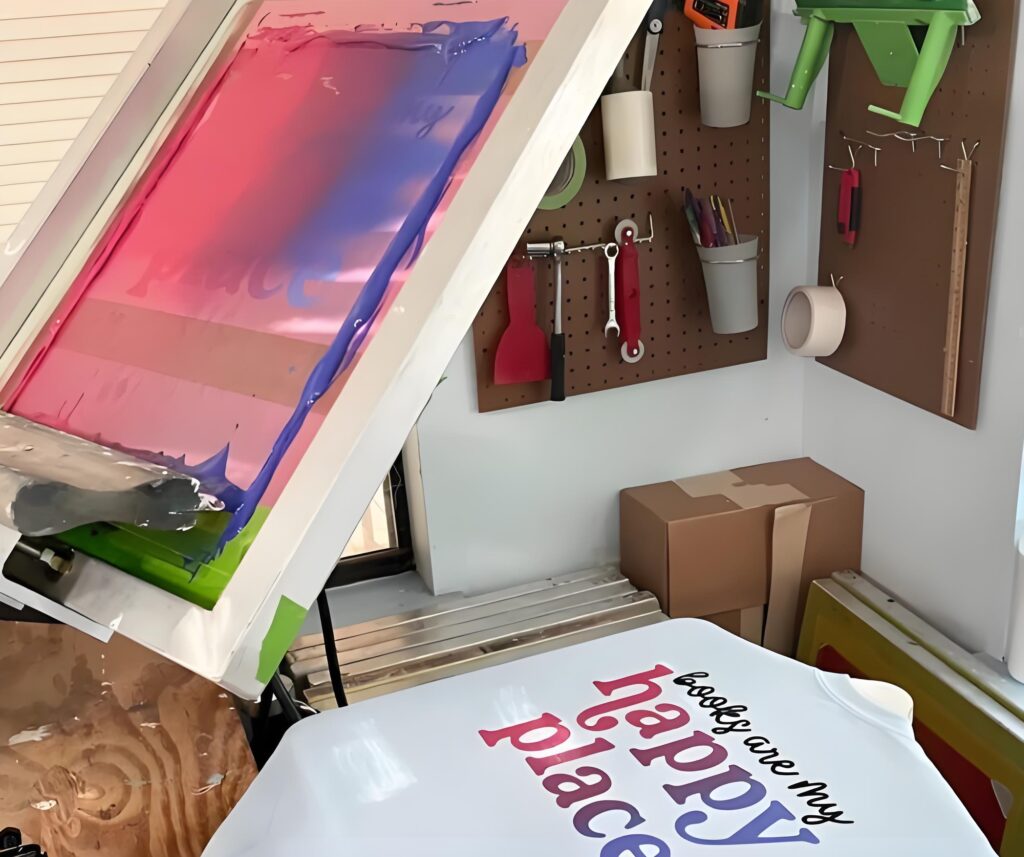

Screen print direct is a procedure where printers and artists use a mesh display screen to switch ink at once onto cloth or clothing. The core of the technique is straightforward: a stencil or “layout” is created at the display screen the usage of emulsion, which blocks out areas in which ink shouldn’t bypass through. When the display screen is set up, ink is pressed thru the uncovered areas, making use of the layout without delay to the garment. This approach is mainly valued for its ability to breed a high level of detail and colourful colours on loads of fabric.

The “direct” component in screen print direct emphasizes that ink is implemented immediately onto the apparel, making it one of a kind from switch strategies in which the design is printed on paper first after which implemented to the cloth. This consequences in prints which are durable, shiny, and feature a expert, incredible look—traits exceedingly widespread via each businesses and hobbyist printers.

Because screen printing needs unique displays, emulsion, and inks for every layout and color, there’s a few preliminary setup time. However, once the setup is complete, it’s a price-effective manner to print big runs of custom garb, making it a famous desire for bulk orders.

2. Why Is Screen Printing the Preferred Printing Method for Custom Apparel?

Screen printing is the cross-to printing technique for most custom clothing as it supplies excellent merchandise with toughness. The method lets in for using plastisol inks, which are acknowledged for his or her ability to sit atop the fabric, producing colourful colorations and crisp, specific strains. Plus, these inks provide exquisite wash durability, maintaining your prints looking fresh after many wears.

Another purpose display printing stands proud is its adaptability. Whether you’re printing on cotton, polyester, or maybe forte blends, display print direct comprises a enormous range of garment sorts. Businesses frequently depend on screen printers to satisfy bulk orders due to the approach’s efficiency and the top class results it elements. The setup might require a while, particularly for complex designs, however the payoff is obvious: a finished product that exceeds expectations for element, coloration, and durability.

3. Screen Print Direct vs. DTG and DTF: Which Printer Is Best for You?

With the rise of latest technologies, it’s herbal to wonder how display screen print direct compares to options like DTG (Direct-to-Garment) and DTF (Direct-to-Film). Here’s a breakdown that will help you pick out:

Screen print direct offers unequalled best for bulk orders and custom garb, mainly in which vibrant colour and sharp detail matter. It’s best for designs that require plastisol inks or forte ink packages, including metallic or puff results—something DTG and DTF frequently can’t reap as nicely.

DTG entails the use of an inkjet printer to apply water-based inks immediately onto a garment. It shines for small orders or while desiring speedy prototyping, however it generally falls short on coloration vibrancy and sturdiness as compared to plastisol screen prints. DTF, in the meantime, prints your layout onto a special movie using inkjet technology; the layout is then transferred and cured onto the clothing. While DTF is incredible for multi-color, intricate designs with out a setup time, it doesn’t healthy the reliability and wash sturdiness of display printing for bulk orders.

For most business printing desires, specially with bulk and custom orders, display screen printing remains the gold standard.

4. What Are the Essential Screen Printing Supplies and Equipment?

Getting started with screen print direct calls for a few important substances and system. At the coronary heart of the procedure are monitors—generally fabricated from exceptional mesh and secured in a body—which keep your design. To switch that layout, you’ll use emulsion, a mild-touchy chemical that facilitates create an in depth stencil on your display.

You’ll also need excellent inks, with plastisol inks being the enterprise favorite for his or her versatility and potential to produce vibrant shade. Other need to-haves encompass a squeegee for pushing ink through the screen, an exposure unit for growing your emulsion with image emulsions, and a dryer or warmth press to cure the ink so it units completely on the garment.rojects. Having reliable equipment and supplies is essential for achieving the high-quality results that screen print direct offers.

5. How Does the Screen Printing Process Achieve Such Vibrant Color and Intricate Designs?

It’s all approximately the chemistry—and the craftsmanship. Screen printing achieves vibrant colours through the usage of remarkable plastisol inks, which stay opaque and ambitious across quite a number clothing types. When a display screen printer prepares the design, cautious interest is paid to detail, ensuring that best traces and complicated patterns are faithfully reproduced on the mesh display screen.

Multi-color designs are handled via the use of separate monitors and emulsions for every shade. This layered technique gives display screen printers the capacity to build up complex pictures with marvelous, colourful hues. For complex designs, the mesh’s fineness and the best of the emulsion play large roles in offering sharp detail, making display screen print direct the top desire for prints where each pixel counts.

6. What Makes Screen Print Direct Ideal for Bulk Orders and Business Needs?

When you need custom clothing speedy, in large quantities, and at a aggressive charge, screen printing is hard to conquer. The setup—even though it requires some time and knowledge—permits display printers to churn out loads or even hundreds of garments with steady first-class and colourful color. This efficiency makes display print direct the primary desire for corporations needing uniforms, event shirts, promotional garb, or resellable merchandise. for businesses and customers alike. Additionally, the reliability and durability of plastisol inks mean fewer returns and happier customers, supporting strong customer service and repeat business.

7. Understanding Ink, Emulsion, and Screen Chemicals in High-Quality Prints

Let’s wreck down the necessities that strength display print direct. Inks, especially plastisol, are the backbone of vibrant, tactile prints. They’re thick, smooth to work with, and bond nicely with maximum garment fabric. Emulsion is a important chemical compound that coats the mesh display. When exposed to mild, regions covered by way of your layout continue to be soluble, permitting ink to pass via simplest those specific areas.

Screen chemical compounds, which include emulsion remover, play a essential position in reclaiming displays. After a print run, printers use these products to clean and strip the emulsion, so the mesh is clean and prepared for brand spanking new jobs. Quality products in each a part of this process guarantee brilliant, steady results and allow display print direct to maintain a popularity for reliability and sturdiness.

8. How Do Screen Printers Ensure Proper Cure and Long-Lasting Garment Prints?

Curing is vital. For a print to face the check of time—enduring infinite washes and wears—the ink need to be cured at the right temperature. Screen printers regularly use conveyor dryers or warmth presses set to specific settings for plastisol inks, making certain that the layout bonds securely with the garment.

Skipping or speeding the therapy dangers cracking, fading, or peeling, that’s why professional display screen printers by no means cut corners. The aggregate of high heat and steady timing effects in durable prints that stay vibrant and special, ensuring each order leaves the printer as a fantastic, lengthy-lasting product.

9. Tips for Placing a Custom Screen Printing Order: What Customers Should Know

Ordering custom garb may be a breeze if you know what to anticipate. First, offer your printer with high-resolution paintings or an in depth layout. Specify the garment kind, colour, and sizes, in addition to any custom necessities for ink type or placement. If ordering in bulk, ask approximately setup time and turnaround, as a few complicated designs may also take longer.

Communicate with your preferred screen printing business about shipping, shipping timelines, and any top rate options like green inks or area of expertise finishes. Good customer support is critical—choose a display screen print direct issuer recognised for reliability and fine. If you’re starting a new enterprise or have ongoing printing desires, ask about reductions for ordinary or large orders.

10.How to Take Care of Screen Printed Apparel: Wash, Wear, and Enjoy

To protect the quality of your custom apparel, follow the care commands out of your printer. Generally, flip garments interior out earlier than washing to reduce abrasion. Use bloodless water and moderate detergent, skipping bleach and cruel chemical compounds. Avoid high warmth within the dryer—grasp drying or the usage of a low placing preserves the print’s detail and integrity.

Proper care ensures your colourful display screen prints ultimate thru masses of washes, keeping the colour ambitious and your garment in premium situation. Whether you’re carrying a custom tee or outfitting a crew, a little attention to element is going an extended way.

Quick Summary: What to Remember About Screen Print Direct and Custom Apparel

- Screen print direct provides vibrant, super, and durable prints for custom clothing via making use of ink at once through a mesh display screen with a chemical emulsion stencil.

- It’s the favored printing method for bulk orders, apparel groups, and jobs requiring intricate designs and premium outcomes.

- Essential system consists of mesh screens, emulsions, plastisol inks, squeegees, and curing machines.

- Good printers constantly attention on proper remedy for wash-resistant, lengthy-lasting effects.

- For custom orders, clean conversation and precise customer support make sure satisfaction, well timed transport, and reliable great.

- Take care of display published clothing by means of laundering nicely to keep shade and detail.

- Compared to DTG and DTF, display screen print direct stays the gold popular for companies and absolutely everyone looking for formidable, dependable custom prints.

Whether you’re a new commercial enterprise, hobbyist printer, or simply need standout custom clothing, deciding on screen print direct is always a clever pass.