Summary: The Key Puff Principles to Remember

- Puff plastisol ink creates bold, soft, 3D prints by expanding during the curing process.

- Mixing the right ratio of puff additive with standard plastisol ink is key to controlling the amount of puff and overall effect.

- Choosing vibrant, opaque ink colors ensures high-impact and durable results.

- Screen printers should use a low mesh count for thicker ink deposit and optimal puff.

- Careful curing—right temp, time, and dryer settings—guarantees the ink puffs and colors last.

- Compatible with cotton, polyester, and blends, but always test on your specific fabric.

- Ready-to-use and safe, look for phthalate-free, low cure, or poly-safe puff inks for maximum versatility.

- Mastering puff printing means more than just a bold look—it’s about durable, professional results on any garment.

Start experimenting with puff plastisol ink in your shop and see your screen prints stand out—next-level style, plus unforgettable tactile impact!

Puff Plastisol Ink: The Ultimate Guide to 3D Prints, Bold Colors, and Fabric Mastery

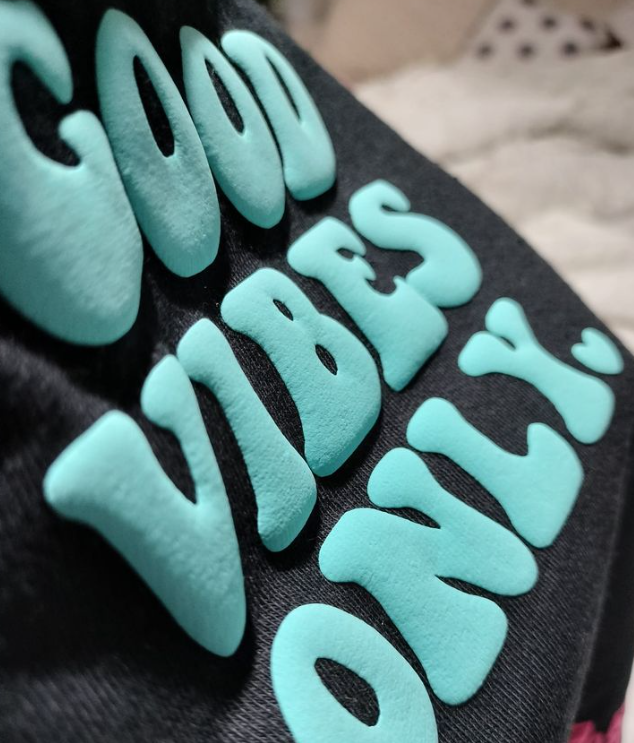

Ever wonder how the ones formidable, 3D-feeling prints on t-shirts feel so alive? That puffy, raised effect is no trick—it’s the magic of puff plastisol ink. Whether you need your subsequent print undertaking to pop off cotton, polyester, or a difficult blend fabric, or you are chasing vibrant, long lasting hues and easy, easy use, this newsletter will display you the way the right puff additive and plastisol ink can transform everyday screen prints into texture-packed statements. We’ll unpack the whole lot you need to recognize approximately puff plastisol ink—from formulating and curing, to pro tips that assure ambitious results. Get geared up to make your prints stand out—literally!

Article Outline

- What Is Puff Plastisol Ink? The Science Behind the Puff

- How Does Puff Additive Transform Standard Plastisol Ink?

- Choosing the Right Puff Ink for Vibrant Color and Texture

- Plastisol Inks vs. Other Printing Inks: Why Puff Wins

- Decoding the Curing Process: Temps, Times & Tricks

- Printing on Cotton, Polyester, or Blend: What Works Best?

- Achieving Bold, Opaque, and Vibrant Ink Colors with Puff

- How To Use Puff Additive: Mixing Ratios and Method

- Tips for Screen Printers: Mesh Count, Ink Deposit, and Dryer Settings

- Solving Common Puff Print Problems: From Flat Prints to Over-Puffing

1. What Is Puff Plastisol Ink? The Science Behind the Puff

Puff plastisol ink is a specialized kind of plastisol ink used in display screen print programs to create a 3-dimensional, raised—or “puffed”—texture on the print floor. Unlike widespread plastisol ink, puff plastisol ink includes a pant additive. The technological know-how? Once you print the ink and it’s cured at the right temp in a conveyor dryer or with infrared warmth (IR), the ink expands, giving it a gentle, tactile experience and a bold, 3-D appearance.

The splendor of puff is the way it takes a preferred ink deposit and actually elevates it, both visually and physically. People love rubbing their palms over a exceptional puff ink print; it transforms a flat picture into something touchable and almost sculptural. Whether you’re after diffused dimension or dramatic, thick puffing, the middle magic is how the ink expands while cured.

2.How Does Puff Additive Transform Standard Plastisol Ink?

At the coronary heart of puff ink is the puff additive. It’s not an ink itself, but a powdered or liquid ink additive that receives blended into standard plastisol ink. When you operate plastisol as your base and blend in puff additive on the recommended ratio, the end result is prepared to apply for display print presses.

During the curing procedure, the chemistry within the puff additive causes the ink to self-praise—consider it as a baking powder for your ink. The amount of puff is determined by each the ratio of puff additive and the amount of ink deposited at the garment. Using too little won’t give you a great deal 3D effect, at the same time as too much may cause over-puffing or lack of element.

Ready-to-use puff inks formulated by way of leading manufacturers frequently blend colourful colour, clean-to-use viscosity, and ideal puffing characteristics in a unmarried bucket. But for custom sun shades or special effects, gaining knowledge of to formulate your personal the usage of puff additive puts you on top of things.

3.Choosing the Right Puff Ink for Vibrant Color and Texture

Not all puff inks are created identical. The best puff plastisol inks offer colourful, opaque color and steady, reliable puffing on every print. When choosing an ink, don’t forget these elements:

Color Brilliance: Look for a pant ink which could create colourful colours, even on dark clothes.

Opacity: Opaque formulation will cover each cotton and polyester base fabric conveniently.

Texture and Feel: The completed puff surface may be smooth, textured, or even matte or smooth, depending for your preference.

The general ink solutions® puff products and puff series inks offered via many main brands come up with a predictable end result with each print. They’re formulated to provide formidable coloration with excessive sturdiness through washing and wear.

4.Plastisol Inks vs. Other Printing Inks: Why Puff Wins

Why use plastisol instead of other printing inks like water-based, discharge, or solvent-based? Plastisol is based-ink, which means it suspends PVC resin and plasticizer together. This unique formula won’t dry in the screen, so you can take your time on tricky prints.

But when you add puff additive, plastisol ink gains another superpower—the puffing effect. While water-based inks can give soft prints, they can’t compete with the deep, 3D effect of well-cured puff plastisol. Plus, modern innovations like phthalate-free and low cure plastisol options make them safer and more flexible than ever.

5.Decoding the Curing Process: Temps, Times & Tricks

The biggest difference between an average puff print and a masterpiece? Mastering the curing process! Puff plastisol ink needs heat to work properly. The curing process involves running your printed garment through a conveyor dryer or applying infrared heat.

Recommended Temp: Standard plastisol and puff plastisol inks usually cure at 320°F (160°C), but check if you have a low cure plastisol or specialty formula.

Time in Dryer: The puffing reaction only occurs if the ink reaches this temp all the way through. A thicker ink deposit will need longer.

Cure Puff Additive: Make sure you don’t “scorch” the puff—over-curing can flatten the puff or dull the effect.

It’s crucial to monitor both the temp and the time to ensure the ink puffs up fully and the color stays vibrant. Some printers also use an infrared thermometer for added precision.

6.Printing on Cotton, Polyester, or Blend: What Works Best?

Can you puff on any fabric? Nearly! Puff plastisol ink is famously versatile, bonding beautifully to cotton, polyester, or tricky blends. Here are some keys:

- Cotton: Great absorbency and smooth puff results.

- Polyester/Poly: Needs an ink designed to block dye migration—look for puff inks labeled as poly-safe or low cure plastisol.

- Blend: Many puff inks are formulated for 50/50 or other blends, but always test first.

Whichever fabric you choose, make sure to use the right mesh count for your screen print; a lower mesh allows for a thicker ink deposit, which is ideal for a dramatic puffing effect.

7.Achieving Bold, Opaque, and Vibrant Ink Colors with Puff

The best puff prints are bold. To ensure bright, stand-out prints, choose a puff ink—or formulate your own—that uses vibrant, opaque pigments. This guarantees your designs remain striking and clear, even after multiple washes.

- Vibrant Colors: Using the right ink colors and mixing method, you can create eye-popping results.

- Opaque Coverage: Especially on dark garments or when using specialty colors, opacity is key.

- Formulate for Texture: Some puff additives let you tweak the surface texture, from smooth to textured or suede-like finishes.

Experiment with different puff series products to find what works best for your project.

8.How To Use Puff Additive: Mixing Ratios and Method

Ready to mix your own puff ink? The typical process goes like this:

- Start with standard plastisol ink—choose your base color.

- Add puff additive—the manufacturer’s ratio suggestions matter. Too much puff can ruin detail; too little gives a weak effect.

- Stir thoroughly so the ink additive is completely blended and no lumps remain.

- Test print on a scrap garment or fabric to check the amount of puff and color clarity.

Always check if your ink is ready to use or if it needs thinning. If you’re using a puff series ink, most are formulated for easy-to-use viscosity.

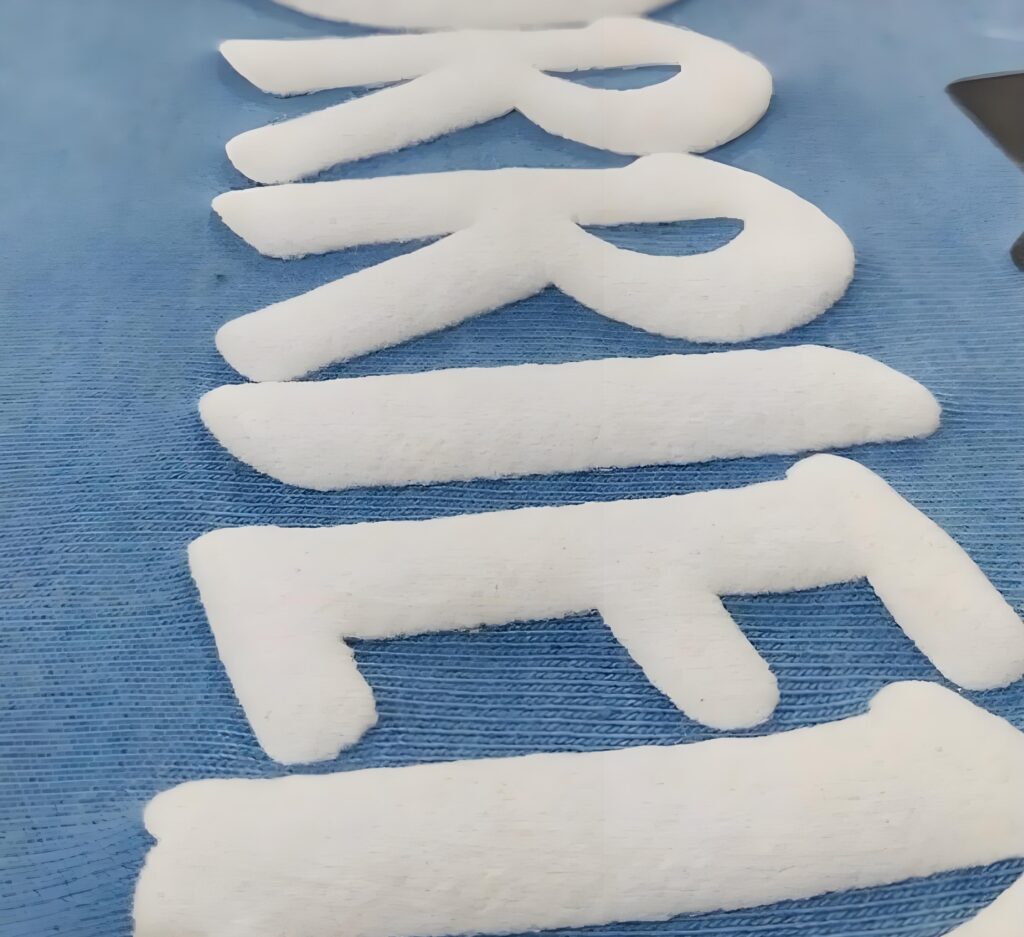

9.Tips for Screen Printers: Mesh Count, Ink Deposit, and Dryer Settings

Professional results come down to the details:

- Mesh Count: Use a lower mesh count (80–110) for thick, even ink deposit. High mesh will starve the print of ink and reduce puff.

- Ink Deposit: The amount of ink matters. More ink leads to more dramatic puffing. Adjust off-contact on your press if needed.

- Dryer Settings: Conveyor dryers and infrared (IR) panels both work. Be sure the garment’s core temp hits the cure target, not just the ink surface.

As with any screen print process, consistency leads to durability.

10.Solving Common Puff Print Problems: From Flat Prints to Over-Puffing

Run into issues? Here’s how to troubleshoot puff plastisol ink:

- Flat Prints: Usually under-cured. Make sure ink reaches cure temp fully.

- Over-Puffing: Too much puff additive, excessive ink deposit, or over-curing can distort detail or over-expand the ink.

- Loss of Vibrancy: Over-curing or using the wrong ratio of ink colors and puff additive can cause dull color.

Test and adjust! Every puff ink, dryer, and fabric combo behaves differently.