Are you equipped to feature a ambitious splash of purple to your next display screen print task? This article explains the whole lot about using warm red and fluorescent crimson plastisol ink—from deciding on the quality ink to your garment to attaining an ideal remedy and vibrant print whenever. If you love the arena of vibrant shade, excessive-opacity, and creative fabrication, you’ll need to hold analyzing. Discover how industry execs use triangle plastisol ink, pinnacle strategies for a dependable treatment, how worldwide coatings simplify your workflow, and why a quart of creamy, equipped to be used ink can rework both guide and automatic screen print jobs. Let’s unlock pro pointers for top notch fluorescent pink screen prints that pop and remaining!

Article Outline

- What Makes a Great Pink Ink for Screen Printing?

- Plastisol Ink: Why It’s the Gold Standard for Bold Color

- How Does Hot Pink Differ from Fluorescent Pink Ink?

- Cure Your Ink: What Temperatures and Techniques Work Best?

- Fluorescent Pink Inks: Stand Out on Every Garment

- Ready for Use Inks: Saving Time and Enhancing Consistency

- From Sheet to Garment: The Print Process Unpacked

- The Science and Art of Pink in Prints

- How Do You Achieve a Perfect Cure with Pink Plastisol Ink?

- What is Fluorescent Pink and How Does It Work?

1. What Makes a Great Pink Ink for Screen Printing?

The perfect pink plastisol ink combines vibrancy, consistency, and opacity for that suitable ambitious announcement on any blouse. A excessive-opacity ink deposit guarantees the color pops, even on dark clothes. Look for inks formulated to combat bleed and dye migration—mainly essential for printing on synthetics and blends.

When attempting to find the nice outcomes, display screen printers pay attention to the creamy consistency and adhesion in their plastisol ink. This allows for smoother prints and higher detail reproduction, whether you’re running with a guide or automatic press. Ready to be used alternatives simplify setup: simply open the quart and get commenced on cotton, jersey, or fleece.

2.Plastisol Ink: Why It’s the Gold Standard for Bold Color

Plastisol ink is the champion of the display screen print world, prized for its durability and capacity to fuse seamlessly into material at some point of the curing method. What sets plastisol display printing inks aside? It’s the mixture of PVC particles suspended in plasticizer, bearing in mind a creamy texture that’s smooth to paintings with and results in formidable, colourful colorings.

Screen printers additionally love plastisol ink for its versatility: it’s appropriate for cotton, polyester, and material blends, making it a go-to for t-shirts, hoodies, and even athletic and amusement clothes. Its durability approach your prints can withstand many wash cycles with out fading, specially if you behavior a proper wash check and cure ink at the advocated temperature.

3.How Does Hot Pink Differ from Fluorescent Pink Ink?

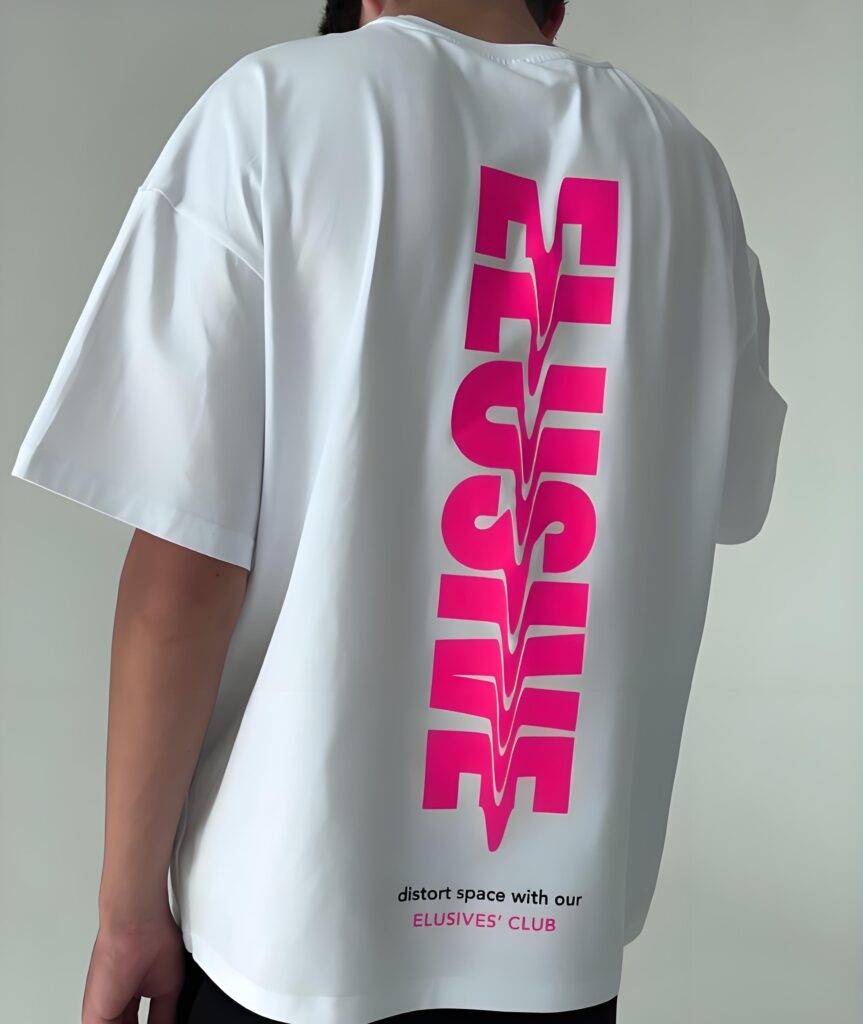

Hot purple and fluorescent pink may both scream excitement, but every brings some thing distinctive to the table. Hot pink plastisol ink promises a saturated, severe colour best for bold statement prints, while fluorescent pink inks crank up the visibility with a neon effect—remarkable beneath UV or direct daylight.

Fluorescent crimson includes special dyes and pigments that react more dramatically to mild, making designs fascinating and almost sparkling in vibrancy. Choose fluorescent crimson for festival shirts, sports clothing, or whenever you want your t-shirts to face out from the group. Both ink types come geared up for use in quart boxes and guide a creamy, opaque utility, whether or not you’re dealing with a single underbase or layering for best consequences

4. Cure Your Ink: What Temperatures and Techniques Work Best?

Curing is the key to expert display print achievement, ensuring the ink fuses properly to the material. The temperature sweet spot for most plastisol ink is around 320°F (a hundred and sixty°C), but low-treatment inks offer flexibility for warmth-touchy substances or when preventing dye migration and bleed.

To cure ink, set your conveyor dryer or flash dryer to the producer’s tips and check live time for uniform consequences. Test dryer temperatures frequently, in particular in case you’re printing on blends, polyester, or fleece, as these can pose demanding situations like elevated dye migration problems or adhesion troubles. Always cure ink completely for high-quality sturdiness, making sure the very last print survives each wash.

5. Fluorescent Pink Inks: Stand Out on Every Garment

Fluorescent crimson plastisol inks are formulated to deliver maximum impact—suppose competition vibes and excessive-energy sports activities occasions. These inks are available in excessive-opacity, low bleed formulations that hold the vibrancy of the coloration even on dark clothes or tough fabric blends.

For safety and compliance, take into account non-phthalate alternatives that meet enterprise requirements, making sure each wearer consolation and eco-duty. A first-class fluorescent red plastisol screen printing ink gives display printers the self assurance their designs will remain ambitious, opaque, and eye-catching lengthy after leaving the clicking.

6.Ready for Use Inks: Saving Time and Enhancing Consistency

Ready to be used plastisol ink is a display screen printer’s secret weapon for efficiency and reliability. These pre-formulated inks take away the guesswork of mixing, offering consistent creamy texture and predictable overall performance directly from the quart.

By the usage of prepared for use ink, screen printers reduce the chance of adding an excessive amount of reducer or different additives, that could lead to adhesion problems, dye migration, or even extended issues with bleed. This is particularly vital when operating with disturbing projects, including wet-on-moist printing strategies or complex artwork the usage of a plastisol underbase

7.From Sheet to Garment: The Print Process Unpacked

Every great screen print starts with a well-prepared screen, optimized mesh counts, and a thoughtfully chosen sheet for test prints. The triangle plastisol ink series offers colors that easily transition from test sheet to final garment, maintaining soft hand and durability on both cotton and polyester blends.

After the flash or initial cure, ensure the ink deposit is uniform and check for any inconsistencies in the color or adhesion. Automatic and manual printers alike should monitor dryer temperature and dwell time to ensure that every print is fused properly and ready to stand up to repeated wash tests.

8.The Science and Art of Pink in Prints

Pink ink isn’t baby’s play—it’s the secret sauce for manufacturers looking to stand out, specially whilst you operate a excellent triangle plastisol ink or strong point formulations from International Coatings. The venture in printing pink is managing colour accuracy and making sure that the pink stays bold, colourful, and opaque even on dark or dyed fabric.

When you formulate plastisol screen inks for pink, the pigments and resins ought to integrate to face up to bleed and dye migration, specially on clothes manufactured from polyester blends. The satisfactory consequences come from balancing mesh counts with ink consistency and using an underbase on darkish shirts to allow your crimson really pop.

By information how dyes and material types affect your prints, you’ll be geared up to deliver shirts, hoodies, and sweats that look excellent below direct daylight—or the brightest spotlights at an occasion. Don’t overlook to run a wash test for durability, making sure your red is built to last from display to street.

9.How Do You Achieve a Perfect Cure with Pink Plastisol Ink?

Curing is non-negotiable while operating with plastisol ink. To get prints that don’t crack, peel, or fade, you need to make sure your ink reaches the proper therapy temperature—generally among 320º F (160º C) and 330º F (165º C)—so the ink fully fuses with the fabric.

For pinks, hot pinks, and fluorescent pinks, correct curing inside the dryer is important to fasten in shade, save you dye migration, and keep the creamy, soft hand customers call for. Always take a look at dryer belt velocity, temperature zones, and adjust reside time so you don’t underneath-therapy or scorch the print. Flash curing between layers can help when printing multi-layer designs or running with high-opacity underbases on darkish clothes.

Test dryer temperatures with a laser thermometer and remedy ink properly before pulling shirts for packing. Remember, ink that appears set however hasn’t absolutely cured is prone to failing overall performance exams—so continually check a sheet or scrap print earlier than jogging a huge batch.

10.What is Fluorescent Pink and How Does It Work?

Fluorescent crimson is wherein things get significantly bold. Formulated using uniqueness dyes and pigments, this playful but colourful ink glows under UV mild and commands interest in daytime too. When you print with fluorescent crimson on cotton, blends, or synthetics, it elevates your layout to pop-tradition reputation.

Unlike fashionable hot purple, fluorescent pink has an depth that makes pictures appear to jump off the garment—best for athletic clothing, streetwear, or promotional t-shirts that call for head-turning attraction. The trick is to apply an appropriate underbase and high-opacity techniques so your pink doesn’t get swallowed by darker fabric shades.

Just as with all specialty ink, fluorescent crimson may have specific curing requirements or sensitivity to direct sunlight through the years. Always take a look at safety information and product sheets for durability and compliance, and check for your precise dryer setup for satisfactory consequences