Non-Blocking Printing ink

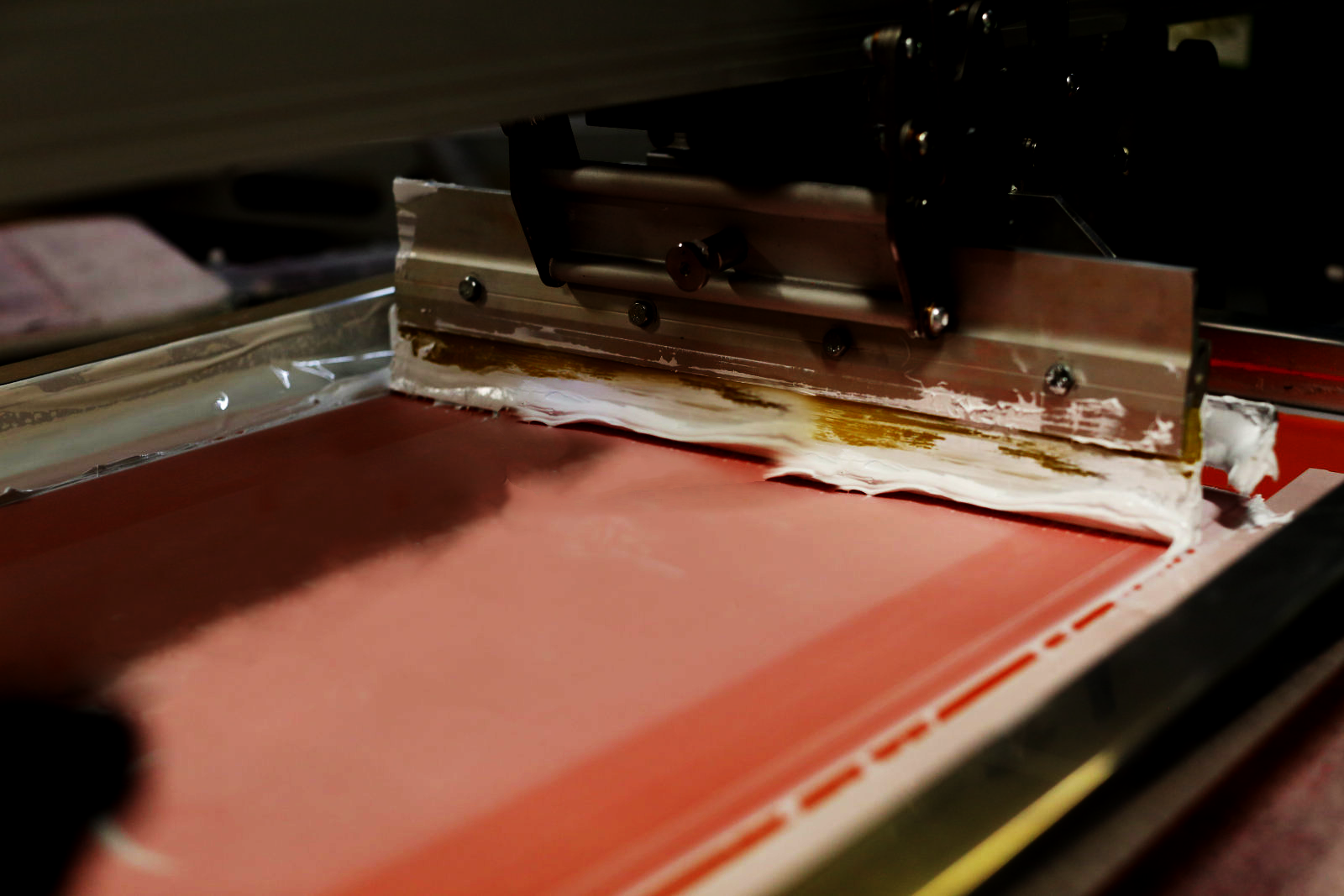

Small particle size, capable of passing through 350 mesh screens. Our ink can remain on the screen for up to 300 hours without cleaning.

Non-Block Ink VS Water-based Ink and Plastisol Ink

The biggest differences between non-block printing ink, Plastisol ink, and water-based ink lie in their composition, application, and performance. Here’s a breakdown:

| Features | Non-Blocking Ink | Plastisol Ink | Water-Based |

| Durability | Very high | Very high | Moderate |

| Fabric feel | Soft to medium | Slightly thick, like plastic | soft, natural |

| Non-Block | Very high | Moderate | Low |

| Breathability | Very high | Moderate | Very high |

| Environmental Protection | High, PVC-free, OEKO-TEX certified | Not very environmentally friendly, contains PVC, etc. | Moderate |

| Cure requirements | Thermosetting, low heat | Heat cure (320°F) | Longer curing time at high temperatures |

| opacity | Very high | Very high | Moderate |

| Easy to use | easy | easy | Need to pay attention to dryness |

| Migration resistance | Excellent | Need blockers | Migration issues on polyester fibers may be difficult to resolve |

| This table compares three types of printing inks: Non-Block Ink, Plastisol Ink, and Water-Based Ink, highlighting their features and performance across several aspects. Below is a detailed analysis: Non-Block Ink: The best overall performance, environmentally friendly, non-blocking, high hiding, durable, easy to use, the most ideal choice. Plastisol Ink: Suitable for high hiding and high durability needs, but poor environmental protection and hard feel. Water-Based Ink: Excellent breathability and natural feel, but slightly inferior durability and hiding power, and need to pay attention to blocking during operation. | |||

Comparison of the effects of Non-Block ink, water-based ink and Plastisol Ink

Non-Blocking Ink

Plastisol Ink

Water-Based Ink

Compatible with various equipment

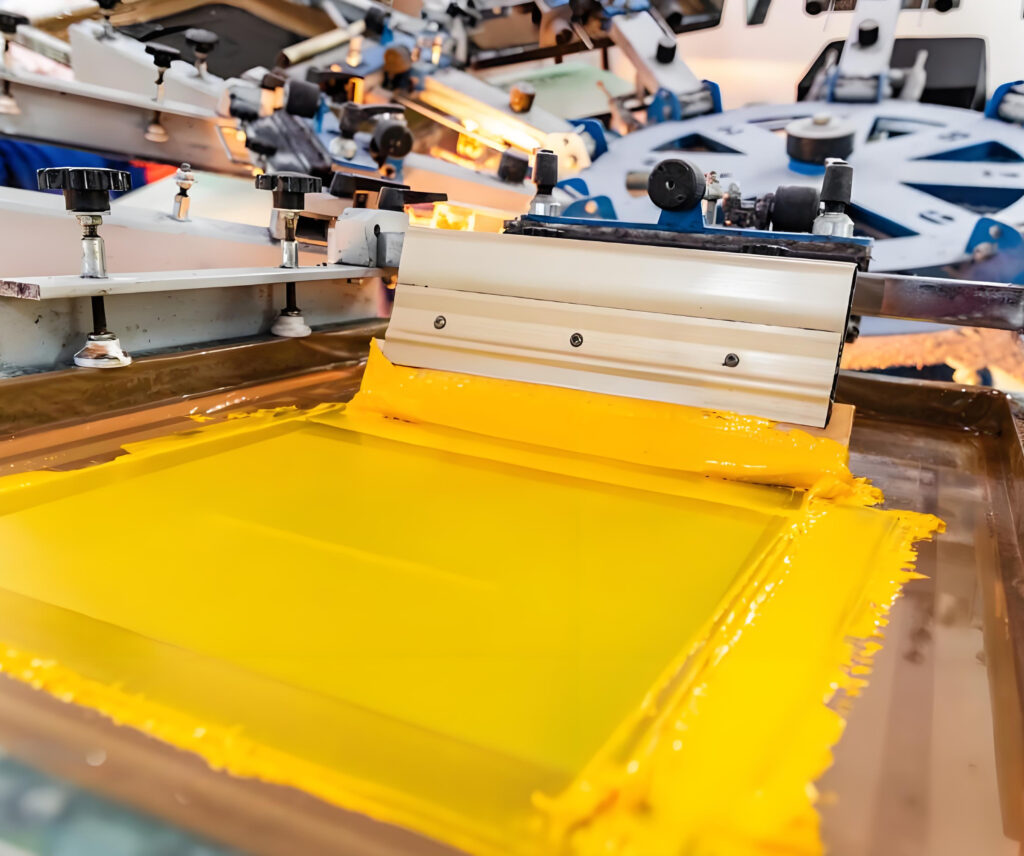

suitable for large-scale machines such as octopus presses and oval machines, with no need to purchase additional equipment.

Why Choose NB Series Ink—Non-Blocking

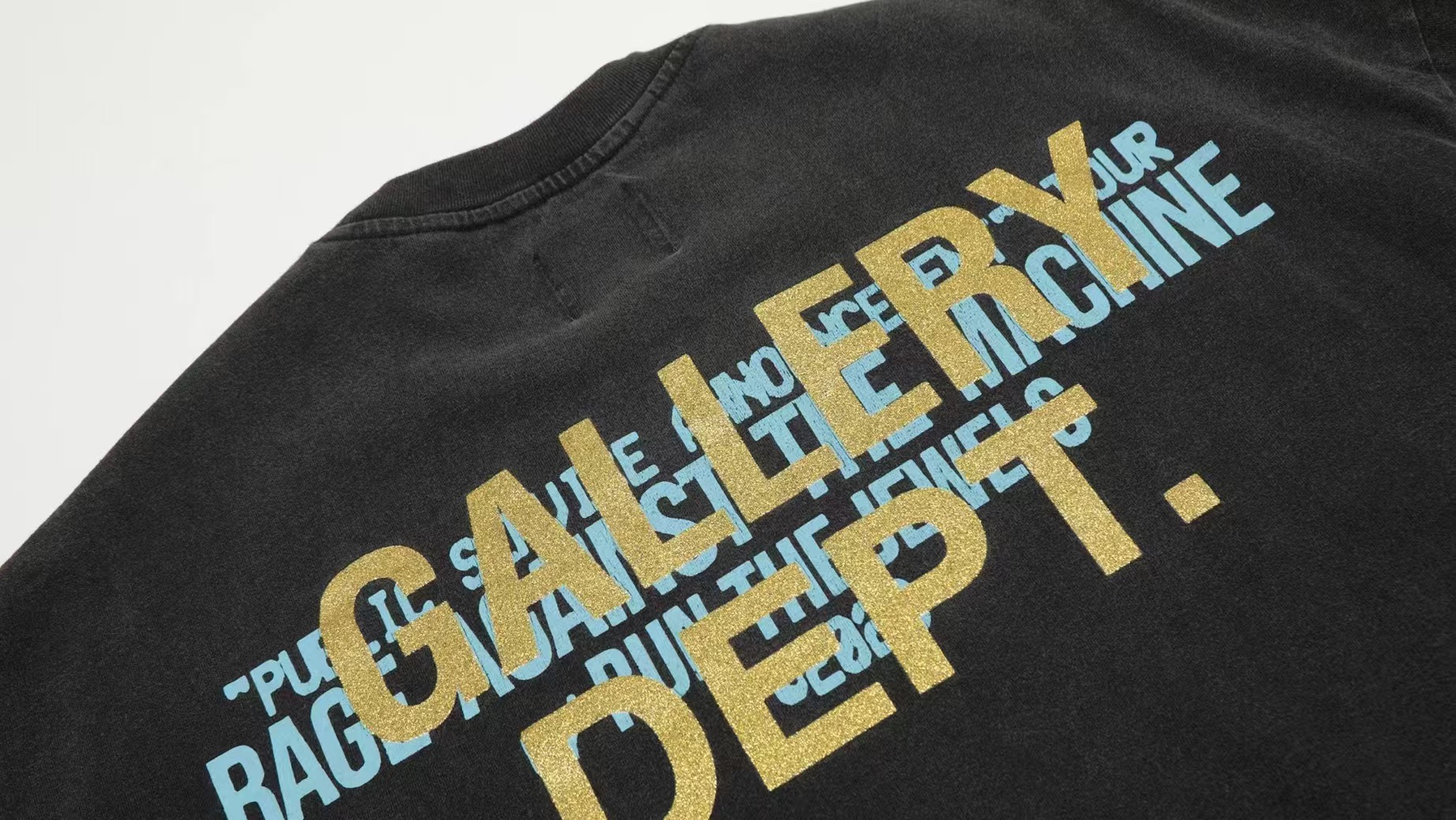

Solves water-based ink blocking issues, simple operation process, identical to plastisol ink workflows.Meets the highest environmental standards, PVC-free and compliant with the quality and environmental requirements of brands such as Burberry, Adidas, Nike, and Calvin Klein.

Why does water-based ink clog the screen?

- Quick Drying Properties: Water-based inks are designed to dry as water evaporates. On the screen, especially during long printing runs, the ink can dry in the mesh openings if not kept moist. This forms a film that blocks the screen and prevents the ink from passing through.

- Environmental Factors: High temperatures, low humidity, or strong airflow in the printing environment can accelerate the drying of water-based inks. This makes the ink dry on the screen mesh rather than on the substrate, leading to clogs.

- Mesh Count and Stencil Thickness: Screens with fine mesh counts or thin stencils are more prone to clogging because they provide less surface area for the ink to stay wet. The smaller mesh openings dry out faster.

- Insufficient Ink Movement: If the ink is not stirred or replenished regularly during the printing process, the water component in the ink can evaporate, increasing its viscosity. This thicker ink tends to block the mesh.

- Extended Print Delays: Pausing the printing process for too long without cleaning or rewetting the screen can cause the ink to dry and clog the screen.

Non-Blocking Ink is an alternative to water-based and Plastisol inks

- Comparative Advantage: Non-Blocking INK surpasses both water-based and thermosetting inks by offering a PVC-free, environmentally friendly solution that is free from harmful substances. Unlike water-based inks that may not perform well on certain fabrics or require additional treatments, and thermosetting inks that involve complex processes and additives, Non-Block INK is Oeko-Tex certified, ensuring safe and sustainable production without compromising on quality.

- Enhanced Performance: Non-Blocking INK is designed to eliminate blocking issues that are common with plastisol inksan water-based inks, reducing the need for costly additives. It offers superior durability, vibrancy, and versatility without the risk of ink migration or incompatibility with fabrics, providing an ideal solution for high-performance, long-lasting prints.

- Target Market:Non-Blocking INK is an environmentally friendly ink, perfect for volume screen printing and brands committed to sustainable textiles. It offers the efficiency of thermoplastic and water-based inks without the environmental impact, allowing companies to meet environmental standards while ensuring superior product performance.

How to Prevent Clogging

- Use a Retarder: Add a retarder to slow down the drying time of water-based inks on the screen.

- Mist the Screen: Regularly mist the screen with water to keep the ink wet during printing.

- Maintain Humidity: Work in a controlled environment with adequate humidity to slow down evaporation.

- Use Screen Openers: Use a screen opener spray to quickly clear any clogs that form.

- Work Efficiently: Avoid long pauses and print at a steady pace to minimize ink drying on the screen.

- Flood Coat: Use a flood stroke to cover the stencil with ink during pauses, preventing it from drying out.

By managing these factors, you can reduce the risk of water-based ink clogging your screen and maintain a smooth printing process.

You must choose the industry’s high-quality, environmentally friendly and affordable products—Non-Block INK

It has the performance of plastisol ink and the characteristics of water-based ink.

We Introducing Non-Block INK, the ultimate solution for screen printers seeking high-quality, environmentally friendly, and affordable printing ink. Combining the best features of traditional plastisol and water-based inks, Non-Block INK is a game-changer in the screen-printing industry.

Performance Meets Sustainability

Unmatched Performance: Delivers the exceptional durability, elasticity, and vibrant colors of plastisol ink.

Eco-Friendly Innovation: PVC-free, free of harmful substances, and compliant with Oeko-Tex certification standards, ensuring safety for you and the environment.

It has the performance of plastisol ink and the characteristics of water-based ink.

Key Benefits

Unmatched Non-Blocking:Designed to eliminate the need for migration-blocking additives, simplifying your printing process.

Thermosetting Ink Advantages:Shares the benefits of thermosetting inks with a smoother curing process and exceptional adhesion.

Environmentally Conscious:Perfect for brands and printers committed to sustainable practices without compromising on quality.

Why Choose Non-Block INK? Non-Blocking INK bridges the gap between plastisol and water-based inks, providing superior opacity, easy handling, and outstanding results on various fabric types. Whether you’re printing on cotton, polyester, Lycra, or blends, Non-Block INK ensures consistent and flawless prints every time.Choose Non-Block INK for a greener, smarter, and more efficient screen-printing experience. Upgrade your printing game today!

Why Choose NB-Block Printing Inks?

Unmatched Performance:

- Highly durable prints that resist cracking and fading, even after countless washes.

- Versatile on fabrics including cotton, polyester, Lycra, and blends.

- Superior opacity for vibrant prints, even on the darkest fabrics.

Design Flexibility:

- Specialty options: Metallic, shimmer, glow-in-the-dark, and chameleon finishes.

- Available in glossy and matte finishes to suit your brand’s style.

- Precision for halftones and fine details, ensuring sharp and professional designs.

Sustainability First:

- PVC-free, eco-friendly formulations certified by Oeko-Tex.

- Free of harmful substances like phthalates and heavy metals.

- Developed to align with brands’ commitment to sustainability.

Ease and Efficiency:

- Low-maintenance inks with excellent screen-clearing properties.

- Long shelf life, stable viscosity, and consistent results.

- Ideal for both manual and automated setups.

Tailored Solutions:

- Custom color matching for brand-specific shades.

- Perfect for small-batch production or high-volume automated printing.