Screen print transfers have revolutionized the world of custom t-shirts, permitting anybody from hobbyists to specialists to create vibrant, lengthy-lasting blouse designs. In this comprehensive guide, you’ll discover the whole lot you need to realize about custom screen print, from the fundamentals of silk screen printing to expert advice on display printing supplies, printing ink, emulsion, stencil making, and more. If you’re captivated with turning your creative principles into lovely published t-shirts, or want to improve your display screen printing talents, this article is your one-forestall shop. Read directly to uncover key techniques, gear, and strategies for getting to know display screen print transfers and bringing your custom apparel visions to existence.

Table of Contents

1.What is Screen Print? Understanding the Basics

Screen print is a flexible printing technique that makes use of a mesh display, ink, and a stencil to switch a design onto lots of substances—most typically t-shirts. This approach, also referred to as silkscreen or silk display printing, dates back over a thousand years, however it’s nonetheless surprisingly popular today way to its capacity to provide colourful, long lasting prints.

The screen print method involves forcing ink thru the open regions of a stencil connected to a mesh screen. The stencil blocks out sections where the ink shouldn’t pass, making sure the photo is smooth and sharp. This is the muse for maximum custom display screen print and screen print transfers seen on apparel, posters, and even business products.

What sets display printing aside is its compatibility with plenty of materials—along with textiles like t-shirts—in addition to its capability to apply one-of-a-kind kinds of printing ink such as water-based totally inks and plastisol. With the proper display printing elements and a simple grasp of the procedure, you could produce the whole thing from easy one coloration designs to complicated, multi-colour masterpieces.

2. Which Screen Printing Supplies Do You Need to Start?

Getting started out with display screen print calls for collecting a few critical display screen printing substances and gadget. At the center of your setup you’ll need a display screen printer—whether or not that is a easy tabletop body or a multi-coloration printing press. You’ll additionally require mesh screens (once in a while referred to as silkscreen or mesh fabric), a squeegee (frequently with a rubber blade), and printing ink inclusive of water-primarily based or plastisol ink.

Other vital substances and equipment encompass emulsion for creating your stencil, a mild source or exposure unit for growing your layout onto the display screen, and cleansing chemical substances to hold your displays. For beginners, display printing kits from brands like Speedball are a handy way to start, as they encompass most of the vital elements and instructions.

When evaluating screen printing resources and system, take note of the mesh depend of your displays—it determines how plenty detail you may seize on your print. Lower mesh counts are perfect for printing on material with thicker inks, at the same time as higher mesh counts healthy best, specific paintings. As your capabilities progress, you could add add-ons like pre-burned monitors, superior printing machines, or distinctiveness inks to satisfy your expanding display printing needs.

3.How Does the Screen Printing Process Work?

Screen print is based on a mixture of artwork and craftsmanship. The method usually begins by preparing a mesh screen for the printed layout. Once a stencil is created (greater on that quickly), it is adhered to the display, blocking certain regions from ink.

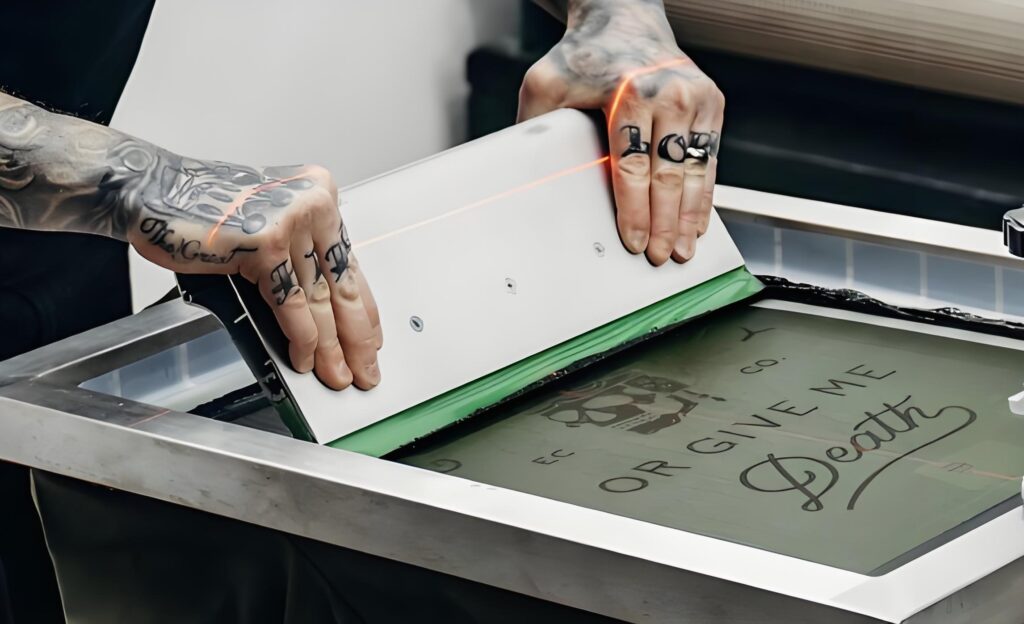

During the printing manner, the printer lays the display flat against the t-shirt or other substrate. Ink is applied onto the display screen and then unfold throughout the display with a squeegee. Pressure from the squeegee pushes the ink thru the open regions of the stencil, depositing layers of ink onto the garment.

For multi-coloured designs, separate screens are prepared for each color. The registration of every display is important to make sure the printed layout aligns well. The inked garment is then cured, regularly with heat, to set the printing ink and ensure durability. This time-examined screen printing approach has remained the pass-to method for mass-generating colourful, wearable artwork throughout all styles of clothing.

4. Choosing the Right Printing Ink: Water-Based vs. Plastisol

Selecting an appropriate screen printing ink is fundamental for expert outcomes. The two most commonplace options are water-based inks and plastisol ink. Water-based inks soak into the fibers of the textile, generating a gentle sense and a matte end. They’re an eco-friendly desire, and ideal for designs wherein a natural appearance is preferred.

Plastisol ink, then again, sits atop the fabric, resulting in colourful colors and excellent opacity—ideal for custom display print t-shirts with ambitious photographs. It’s the maximum famous preference for business display screen print shops thanks to its ease of use and compatibility with a extensive sort of substances. Plastisol additionally calls for a warmness supply to cure, which sets the layout for lengthy-lasting wear with out fading.

When figuring out among water-primarily based and plastisol ink, remember the favored end, your printing equipment, and the fabric being published onto. Both provide precise advantages, and skilled printers can also stock each types to enlarge their innovative and industrial display printing merchandise.

5. What Role Does Emulsion Play in Screen Printing?

Emulsion is a mild-sensitive liquid critical to the screen print method. This liquid, once carried out onto the display screen, is used to create the stencil, which controls wherein ink passes via the mesh and where it is blocked. To form the stencil, a layout is first printed onto acetate film and overlaid onto the lined screen.

The display screen is then exposed to a bright light supply, like an exposure unit. The photo emulsion hardens anywhere that light hits. The areas blocked by the layout at the acetate continue to be tender and may be washed away, developing open spaces inside the mesh screen for ink to bypass via. This approach lets in you to without problems reproduce complicated images and certain blouse designs.

Choosing the right emulsion and nicely exposing it are essential for sharp, long lasting stencils. Whether you’re the use of water-primarily based or plastisol ink, getting to know emulsion application is vital in silk-screen printing for fantastic revealed designs.

6.How to Create the Perfect Stencil for Your T-Shirts

The stencil is the heart of each screen print challenge. Creating a exceptional stencil ensures your published t-shirts flip out crisp and correct. The process begins with a virtual design, which is printed in stable black onto acetate movie. This movie is then located onto the screen covered in picture emulsion.

After exposing the display screen to a light source, you rinse the unexposed areas, revealing the stencil. The higher the contact among the acetate film and the emulsion-lined mesh screen, the sharper the print. For complicated, multi-shade prints, you may need separate stencils and monitors for every layer of ink.

Don’t overlook quality tuning your stencil-making process—the usage of an appropriate mesh count number, flippantly covered emulsion, and a reliable publicity unit. Professional display printers regularly put money into pre-burned screens for famous or repetitive designs to store time and make certain consistency throughout runs.

7. How Screen Print Transfers Make Custom Printing Easy

Screen print transfers deliver a new stage of versatility to the custom display print world. Instead of printing immediately onto the t-blouse, you first follow ink onto a special switch paper the use of the display screen printing approach. Once dried, the layout is implemented to the textile the usage of a warmth switch press.

This technique gives you the power to print designs earlier and observe them onto garments while wanted. It’s mainly useful for custom orders or whilst you need to offer a number of blouse designs with out producing every one from scratch. Screen print transfers offer the same shiny colorings and durability as direct printing, making them a favorite amongst small commercial enterprise owners and DIY fans.

Using display screen print transfers also allows you to control inventory and respond quick to client needs. With the proper display screen printing substances and expertise, anyone can dive into warmness switch display printing with minimal trouble at the same time as reaching professional effects.

8. How to Use a Screen Printer: Tips for Beginners

Operating a screen printer may additionally appear daunting, however with some middle techniques, all and sundry can produce crisp, pleasant prints. Begin with the aid of putting in place your display screen print body securely, making sure the mesh display is taut and clean. Affix your stencil, and then align your t-shirt or material below the display for accurate placement of your revealed design.

With your chosen printing ink loaded at one give up of the screen, use a squeegee with a rubber blade to tug the ink across the display at a constant angle and pressure. This helps push the ink via the open areas of your stencil and onto the t-shirt. Lift the display screen carefully, and therapy the print the usage of warmness as required for your preferred ink.

Practicing on take a look at material or paper first can help you locate the proper balance of ink, stress, and squeegee angle. Over time, even novice screen printers broaden a feel for the procedure, optimizing their method for a variety of materials and printed t-shirts.

9. Essential Supplies and Equipment for Quality Results

Quality screen printing supplies and equipment can make all of the distinction between a mediocre and a pro-looking display screen print. Aside from the primary mesh displays, squeegee, and ink, take into account making an investment in a dependable exposure unit for constant stencil advent, and an amazing cleansing setup to keep your displays.

Professional display screen printing setups frequently consist of a printing press for quicker, multi-blouse manufacturing, and gadgets like a flash dryer or conveyor dryer to cure printing ink effectively. Accessories including pre-burned monitors permit for multi-design flexibility, at the same time as excessive-grade mesh material offers durability and unique element.

When assembling your display printing elements and gadget, pick merchandise designed on your specific display screen printing needs. Whether you’re printing on material, paper, or different substances, having the proper equipment ensures your display screen print transfers and direct prints consistently meet high requirements.

10. Expert Techniques for Professional Silk Screen Printing

Silk display (or silkscreen) printing is accelerated from precise to exceptional with mastery of approach. Professionals best the tension of their mesh, the attitude and pace of the squeegee, and make sure even insurance of more than one layers of ink. Proper display registration is vital for multi-color prints, and a sharp eye for detail will reduce misprints.

Using uniqueness inks—like steel, glow-in-the-dark, or discharge—can enlarge your creative repertoire. Mastery of image emulsion and superior stencil techniques opens up intricate designs and texture consequences. Experimentation with mesh matter, ink thickness, and curing instances allows you to tailor every screen print to the substrate, whether or not you’re operating with cotton t-shirts, polyester blends, or even non-fabric items.

Professional silk-display screen printing is as a great deal approximately education as execution. Clean, well-maintained screens, precise emulsion coating, and most desirable garage for printing ink and substances will maintain your setup going for walks smoothly as you enlarge your lineup of display printing products.

11. Troubleshooting Common Screen Print Issues

Even pro display printers run into problems all through the printing method. Ink bleeding, patchy prints, and smudged designs are all not unusual pitfalls. To keep away from those problems, begin with smooth monitors and calibrated equipment. Ensuring balanced mesh count number, effectively mixed printing ink, and correct squeegee method is crucial.

If your emulsion is washing away or now not exposing successfully, double-test your publicity unit, mild source, and the emulsion’s age and excellent. Inconsistent ink deposition may be a sign of fallacious mesh tension or a worn-out squeegee. Regularly test your supplies and gadget for put on and tear and update objects like rubber blades or monitors as needed.

Continuous learning and experimentation are part of the journey. By meticulously reviewing each step of your display print procedure, you may refine your craft and continually produce top-tier custom display screen print transfers and direct-to-garment designs.

Key Takeaways: What To Remember About Screen Print and Supplies

- Screen print is a time-examined printing method exceptional for t-shirts, apparel, and other materials.

- Master the fundamental display printing resources and equipment: mesh display, squeegee, emulsion, printer, and ink.

- Choosing between water-primarily based inks and plastisol ink relies upon for your display printing desires and desired end.

- Emulsion and proper stencil creation are on the coronary heart of each crisp, exact printed layout.

- Screen print transfers allow for flexible, efficient solutions, mainly for custom or small-batch orders.

- Regular cleansing and protection of your silkscreen resources make sure constant, outstanding prints.

- Acquiring the right mesh count number, exposure unit, and printing press boosts both reliability and output high-quality.

- Troubleshoot issues by using checking mesh tension, ink nice, and emulsion publicity.

- With the right strategies and screen printing merchandise, all of us can create professional-grade printed t-shirts.

- Continued exercise and investment in resources will assist ideal your craft and extend your innovative opportunities.

Start your screen print journey today with confidence, armed with the knowledge and resources to transform ideas into wearable art!