Table of Contents

Mastering Screen Printing: The Role of Transparencies

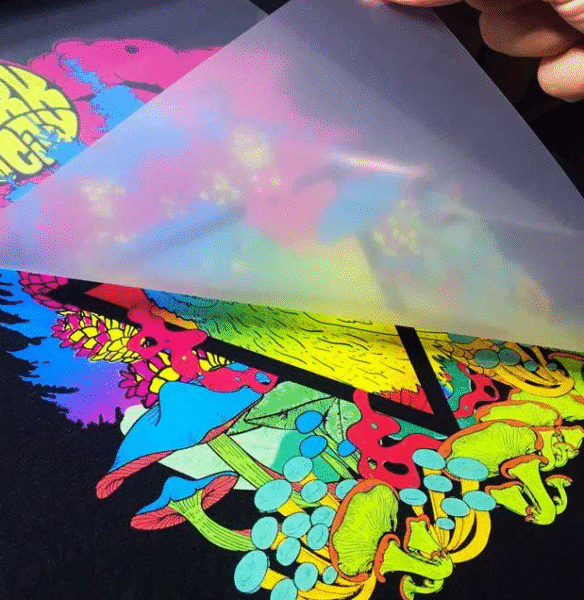

Why do transparencies matter in screen printing? Transparencies (also called film positives) are special sheets that help transfer your design to a screen. They are key to making clear, bright prints. Let’s learn how to use them right!

What Are Transparencies?

Transparencies are clear sheets with your design printed in black. Light shines through them to make a stencil on the screen.

Key Facts:

- Positive films: Black areas block light.

- Negative films: Clear areas block light.

- Opacity matters: Darker films = better stencils.

- High resolution: Use 1200+ DPI for tiny details (like halftones).

Example: Clemson University found 1200+ DPI films kept 40% more details in posters.

Tools You Need

1. Best Films

- Fixxons HD: Stops 70% fewer pinholes (Ryonet study).

- Chromaline: Works with plastisol ink.

2. Software

- Adobe Illustrator: Draws sharp designs.

- AccuRIP: Cuts ink waste by 50% (Screen Printing Magazine).

3. Printers

- Epson SureColor: Prints high-resolution films.

| Tool | Why It’s Good |

|---|---|

| Fixxons HD Film | Less misalignment |

| AccuRIP Software | Saves money |

| Epson Printer | Clear details |

Step-by-Step: Making Transparencies

1. Design Your Art

- Use vector art (not blurry).

- Add registration marks to line up colors.

2. Print

- Set printer to 1200 DPI.

- Let ink dry to stop smudges.

Tip: Fixxons films with anti-static coating cut errors by 30%.

Exposing Screens

1. Coat Screens

- Use Ulano photopolymer emulsion (25% faster than diazo).

2. Exposure Time

- UV light hardens emulsion.

- Test with step-wedge for best time.

| Problem | Fix |

|---|---|

| Stencil washes out | More exposure time |

| Pinholes | Clean screen |

Fact: Anthem exposure units with >12 Hg pressure give 98% contact.

Common Mistakes

- Blurry Films: Check printer DPI.

- Underexposure: Use step-wedge test.

- Misalignment: Add registration marks.

SGIA Survey: 45% of errors come from bad films.

Advanced Tips

1. Multicolor Prints

- Use trapping to overlap colors.

2. Special Inks

- Glow-in-the-dark inks need thicker stencils.

Nazdar Data: 90% ink transfer with 230-mesh screens + HD films.

Pro Tips

- Store films in dry places.

- Reclaim screens fast with Saati chemicals.

| Pro Tip | Result |

|---|---|

| Use high-opacity films | Fewer defects |

| Test exposure time | Save time |

FAQs

Can I reuse transparencies?

Sometimes, if they’re not scratched.

Conclusion

Transparencies are key to great prints. Use high-DPI films, test exposure times, and ask questions!