Table of Contents

Innovative Applications of Reducer Plastisol in the Plastics Industry: Revolutionizing Manufacturing in 2024

Reducer plastisol is changing how we make plastic products. It is a special liquid used in cars, hospitals, and factories. This article will show how it helps make things better and safer.

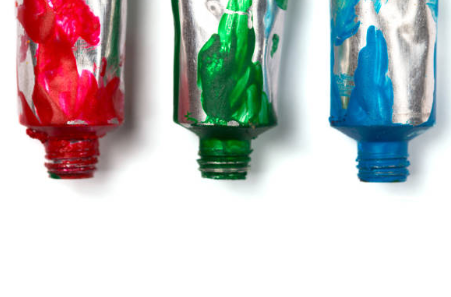

What is Reducer Plastisol?

Reducer plastisol is a PVC-based liquid polymer. It is mixed with viscosity modifiers to make it easy to use. Here’s why it’s important:

- Makes products flexible and strong.

- Sticks well to surfaces.

- Works in many industries.

People ask: “What is reducer plastisol, and why is it important?”

Why Reducer Plastisol Matters Now

Reducer plastisol is popular because:

- Cost-effective manufacturing: Saves money.

- Thermal stability: Works in hot or cold conditions.

- Low-VOC formulations: Safer for the environment.

| Old Plastisol | New Plastisol |

|---|---|

| Harmful chemicals | Non-phthalate plasticizers (e.g., Eastman 168™) |

| High pollution | Eco-friendly solutions |

| Limited uses | Used in electric vehicles (EVs) and medical devices |

Big companies using it: BASF SE, Dow Chemical, and Wacker Chemie AG.

5 Breakthrough Applications of Reducer Plastisol

1. Automotive Lightweighting

Reducer plastisol helps make cars lighter and safer:

- Underbody anti-corrosion coatings: Protects car parts.

- Interior components: Makes seats and dashboards.

- EV battery insulation: Keeps batteries cool.

Companies using it: Tesla, Ford Motor Company.

| Benefit | Example |

|---|---|

| Less weight | Cars use less fuel. |

| Longer life | Parts don’t rust. |

2. Medical Device Innovation

Reducer plastisol is safe for hospitals:

- Dip-molded surgical tools: Easy to clean.

- Biocompatible seals: Safe for skin contact.

- Sterilizable coatings: Kills germs.

Companies using it: Baxter International, Eastman Chemical.

Rules: Must follow FDA compliance.

3. Eco-Friendly Packaging

Reducer plastisol helps the planet:

- Recyclable films: Used in food wraps.

- Biodegradable blends: Breaks down naturally.

- Food-grade plastisol: Safe for snacks.

Companies using it: Green Dot Bioplastics, Susterra® bio-plasticizers.

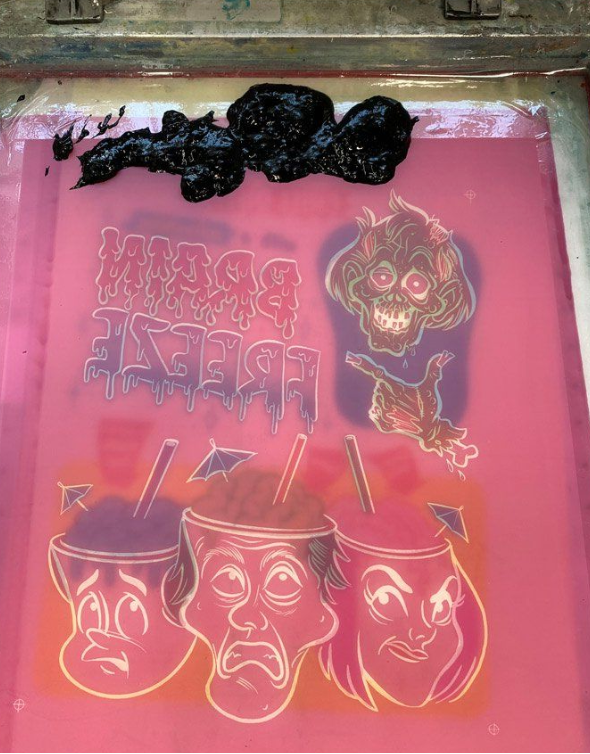

4. Industrial 3D Printing

Reducer plastisol makes 3D printing better:

- Rapid prototyping molds: Quick to make.

- High-resolution finishes: Smooth surfaces.

Key terms: Thixotropic agents (makes liquid thicker when still), additive manufacturing.

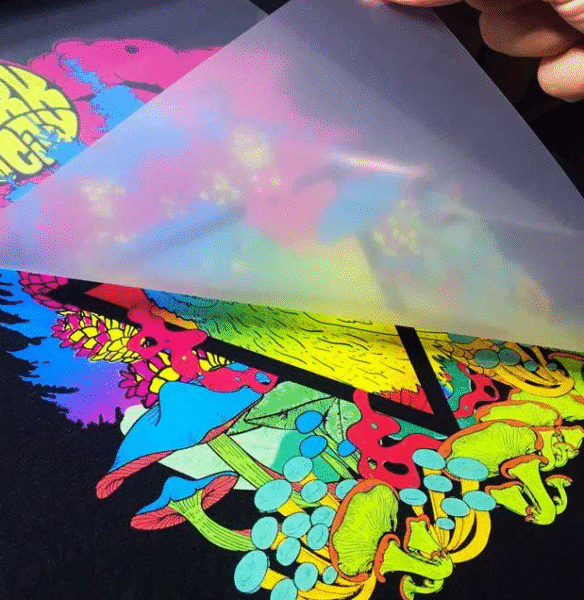

5. Smart Textiles & Footwear

Reducer plastisol is in clothes and shoes:

- Seamless adhesives: No stitches needed.

- Anti-slip soles: Safe to walk.

Example: Adidas AG uses it for sports shoes.

Technical Challenges & Solutions

Problems

- Bubbling/degassing: Air pockets form.

- Slow curing: Takes time to dry.

- Temperature sensitivity: Melts or cracks.

Solutions

- High-shear mixing: Removes air bubbles (used by Teknor Apex).

- Hybrid additives: Speeds up drying (e.g., Arkema’s rheology modifiers).

- ASTM/UL-certified formulas: Safe for all temperatures.

Sustainability: The Future of Plastisol

Green innovations include:

- Non-phthalate plasticizers: Safe chemicals (e.g., Palatinol®).

- Closed-loop recycling: Reuse materials (Avient Corporation example).

- EU REACH/EPA rules: Laws for cleaner products.

| Innovation | Impact |

|---|---|

| Recyclable plastisol | Less waste in landfills. |

| Bio-plasticizers | Healthier for workers. |

Future Trends to Watch

- Conductive coatings: For phones and computers (Mitsubishi Chemical).

- Self-healing surfaces: Fixes scratches automatically (Fraunhofer Institute).

- Nano-additives: Makes products last longer.

Conclusion

Reducer plastisol is used in cars, hospitals, and eco-friendly packaging. Companies like Dow Chemical and Solvay SA lead the way.

Call to Action: “Work with these companies to make better products!”

FAQs

Is reducer plastisol safe for medical devices?

Yes! It follows FDA compliance rules.

How does plastisol reduce manufacturing costs?

It dries fast and needs fewer materials.

Can plastisol be recycled?

Yes! Use closed-loop recycling systems.