Key Things to Remember

- White ink is the muse of every colourful display screen print. Mastering it makes all of the difference.

- Always pick out low bleed plastisol ink for garments liable to dye migration, specially poly and blends.

- Look for high opacity, creamy consistency, and coffee-cure temperature for the high-quality low bleed white ink.

- Sample and evaluation products from leading ink manufacturers—don’t accept 2nd-nice.

- Proper curing at producer-special temperatures is critical to prevent migration, scorch, and washout.

- Manual and automated presses both paintings notable with present day low bleed ink, but select ink formulas first-rate for your setup.

- Use best practices and protection protocols for all your display screen printing components and device.

- Always read opinions, protection records, and technical sheets before shopping supply or switching ink brands.

- Regularly check your print strategies to guarantee constant, colourful, and long-lasting outcomes.

- The proper mixture of ink, method, and gadget equals professional, eye-popping display revealed clothes on every occasion.

Armed with those insights, you can tackle any screen print assignment with confidence—handing over perfectly opaque, long-lasting white prints on each material and fashion your business demands. Happy printing!

How to print low bleed white plastisol ink

Are you bored with murky whites and dye migration ruining your colourful display screen print designs? If you care approximately achieving sharp, opaque white prints on difficult fabrics like polyester or blends, you’re within the proper region. In this comprehensive article, we’ll discover white ink, low bleed plastisol, and the fine practices to get top-tier outcomes on every occasion. Discover the way to select the first-rate low bleed white plastisol ink, a way to properly remedy ink for colourful prints, and which supply essentials you could’t live without. Whether you’re a beginner or a seasoned screen print pro, this guide will arm you with everything you need to grasp the artwork of the precise print.

Article Outline

- What Makes White Ink Different in Screen Printing?

- Why Is Low Bleed Plastisol Ink Essential for Screen Print Success?

- How to Identify the Best Low Bleed White Ink?

- A Review of Top Plastisol Ink Brands and Their LB White Offerings

- Secrets to Achieving Maximum Opacity and Opaque Prints

- Low-Cure and Low Bleed: Do You Need Both?

- Proper Curing: How to Cure Ink for the Best Results

- Manual and Automatic Presses: What’s Best for Low Bleed Ink?

- Best Practices for Printing on Polyester Blends and Dark Garments

- Tips for Safe, Efficient, and Vibrant Screen Printing Supply Use

1.What Makes White Ink Different in Screen Printing?

White ink is the true litmus take a look at of a display screen printer’s ability. Unlike other ink hues, white ought to provide maximum opacity—even over dark garments—and block dye migration from tough polyester or poly blends. Many printers conflict to obtain a colourful, opaque, and creamy white print, particularly whilst the use of popular plastisol ink rather than specialised formulations.

The most important reason white ink is so complicated? The colour white is certainly less pigmented, so it needs a higher stage of opacity to prevent dyes from bleeding through. That’s where specialized white plastisol ink and in particular low bleed white answers come into play. Their creamy consistency, higher solids content, and specialized components supply superior opacity and clean coverage that standard ink can’t match.

It’s now not just about seems, though. White ink also must be tough—able to stretch with the garment, resist lots of wash cycles, adhere firmly, and therapy very well to satisfy professional manufacturing standards. That’s why the right white ink alternatives set the muse for all beautiful screen print jobs.

2.Why Is Low Bleed Plastisol Ink Essential for Screen Print Success?

Dye migration—from time to time known as “bleed”—is the arch-enemy of crystal-clear prints on artificial garments like polyester or poly blends. Standard plastisol ink regularly falls sufferer to this phenomenon, where the garment’s dye migrates into the ink throughout the print curing method. The end result? Dull, purple-tinted whites or muddy hues that damage your complete run.

Low bleed plastisol ink uses a unique base and additive package to block this manner. With amazing low bleed ink, you can confidently print on light or dark polyester, cotton-poly blends, or even athletic uniforms prone to dye migration. LB white inks incorporate greater blockers and usually remedy at lower temperatures (low-remedy) to in addition decrease the chances of scorch or dye migration.

For any shop aiming for colourful results and regular production throughout a variety of fabric, low bleed plastisol is quintessential. Not handiest does it provide remarkable bleed resistance and high opacity, however it also simplifies the supply chain via disposing of regular ink-blending or substrate issues.

3.How to Identify the Best Low Bleed White Ink?

Choosing the high-quality low bleed white for screen print tasks isn’t just about choosing any ink labeled “LB White.” Top-tier low bleed white inks have several standout characteristics:

- High Opacity: Delivers crisp, colourful colour even over darkish garments with simply one or passes.

- Creamy Consistency: Spreads easily at the display and works tremendous for each manual and automated presses.

- Low-Cure Temperature: Enables faster production speeds and reduces the risk of dye migration or scorch, since ink is about at a decrease temperature.

- Excellent Bleed Resistance: Specifically formulated to dam dye from synthetic fabrics.

Check opinions for brands that deliver on these guarantees. Look for those that provide small quart or massive five gallon pails depending on your production needs. Your supply preference ought to include dependable low bleed white ink to assure colourful final prints.

4.A Review of Top Plastisol Ink Brands and Their LB White Offerings

Let’s assessment a number of the maximum-reputable ink producers in the enterprise. International Coatings, for instance, has lengthy been celebrated for its excessive-opacity white plastisol ink with enterprise-leading bleed resistance and creamy texture. Many printers praise their LB White formulas’ block against dye migration—vital for polyester and mix jobs.

Other ink producers provide low bleed ink with particular components or bases for exceptional fabric demanding situations. Consider performing your very own ink evaluation by way of trying out a brief run with leading manufacturers—compare their opacity, ease of remedy, and ability to block dye to your equipment. Always check the manufacturer’s safety information for lead-loose certifications, specifically for garment or t-blouse manufacturing destined for kids or global clients.

No matter what, the great low bleed plastisol ink should take care of manual and automated presses, provide you with a high degree of manage, and live up to its claims of opacity and bleed resistance. Read lots of opinions, and in no way hesitate to touch your deliver distributor for pattern quarts before committing to a 5 gallon pail.

5.Secrets to Achieving Maximum Opacity and Opaque Prints

High opacity and a thick, opaque appearance are non-negotiables for stunning white print consequences, in particular on dark garments. Achieving this calls for greater than simply picking the proper white plastisol ink. You additionally want to installation your display screen printing ink well—the use of an appropriate mesh matter, anxiety, and stale-touch on your screen.

Low bleed white ink, with its creamy consistency and excessive solids base, helps block out any dark fabric beneath and maintains prints colourful and crisp. You may additionally want to double-hit or “flash” the layout between passes to build up the opacity in addition.

Always keep an eye on ink stretch and adhesion; high-opacity ink that cracks or peels after a few washes won’t help your recognition. Test your ink beneath actual manufacturing conditions to make certain the excellent results and lasting prints.

6.Low-Cure and Low Bleed: Do You Need Both?

More often than not, yes. While low bleed is important for stopping dye migration on polyester or blends, low-cure ink formulations will let you remedy ink at lower temperature—frequently as little as 270°F to 300°F—slicing down the chance of scorch, shrinkage, or dye disasters.

Low-therapy low bleed white ink is crucial while you need to print on warmness-touchy synthetic textiles or athletic tools. The mixture of additives in those ink sorts both resists dye migration and completely fuses at lower temperatures, presenting multiplied manufacturing efficiency.

If you’re extreme approximately screen printing on polys, look for white low bleed plastisol ink that mainly touts low-therapy as a function. This not only protects fabrics and forestalls dye issues, but also saves you treasured time and reduces energy costs.

7.Proper Curing: How to Cure Ink for the Best Results

Properly curing plastisol ink is as important as choosing the right ink. Undercured prints will crack, fade, or fail to dam dye migration. Overcure can reason scorch or brittle prints, in particular on artificial or blended clothes.

Set your system to fit the ink’s remedy temperature, and always use an correct warmness gun or probe to confirm the ink film’s temperature—now not just the conveyor dryer’s thermometer. For low bleed white, the correct therapy ink temperature is typically decrease, around 270°F-three hundred°F, though the precise product may additionally range. “Flashing” between passes can also help lock down underbases or construct opacity while layering colors.

Remember, great outcomes come from following each your ink and device producer’s pointers. Skipping even small steps can spell catastrophe for your display screen print run.

8.Manual and Automatic Presses: What’s Best for Low Bleed Ink?

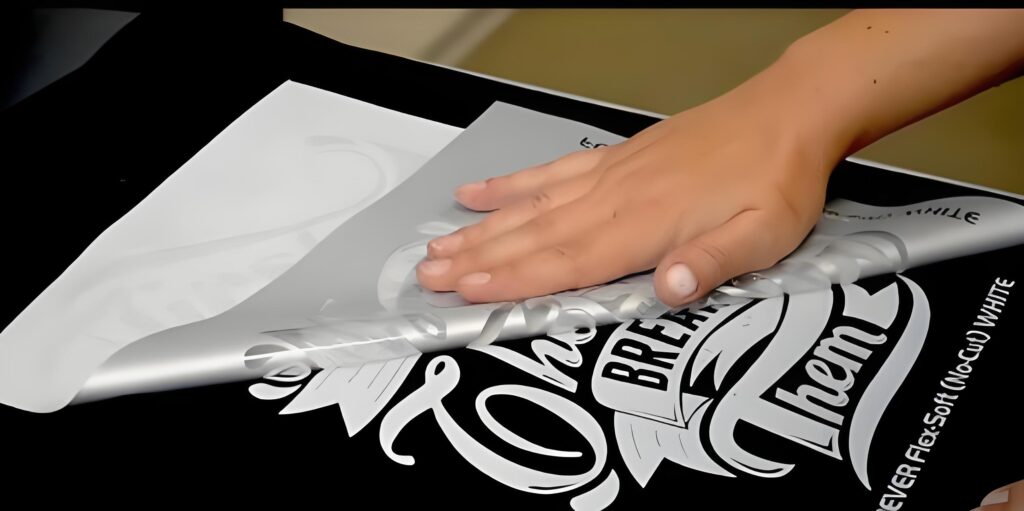

Modern low bleed white plastisol inks are designed to paintings easily on each manual and automated presses. Manual presses typically come up with extra flexibility and control whilst adjusting for mesh tension, squeegee pressure, and off-contact, all of which help reap an opaque, creamy ink layer.

Automatic presses, in the meantime, are important for high-extent manufacturing and regular results throughout masses—or heaps—of clothes. When using automatic presses, make certain your low bleed plastisol keeps a creamy consistency, so it does not clog the screen or demand excessive strain.

Your supply selections ought to replicate your workflow. Some low bleed inks are formulated thinner for automated presses, at the same time as others offer extra body for guide work. Read product statistics and evaluations to locate the high-quality fit to your manufacturing and system.

9.Best Practices for Printing on Polyester Blends and Dark Garments

Printing white ink on polyester, polyester blends, or dark garments demands perfect deliver selections and dialed-in technique. First, continually use true low bleed white plastisol ink to beat dye migration. Second, take a look at remedy settings on a pattern shirt to find the lowest powerful temperature.

Use a good, moderate mesh matter display screen—no longer too open or closed—for best ink coverage. A double-hit with a flash between can help increase opacity, especially if tremendous, vibrant effects are your quit purpose.

Finally, ensure your ink base or additive applications are like minded with your particular garments and strategies—distinct blends require barely distinct processes to maximize adhesion and reduce migration or scorch.

10.Tips for Safe, Efficient, and Vibrant Screen Printing Supply Use

Keep your keep and group secure by using continually checking the Safety Data Sheets (SDS) for every ink and additive in your supply chain, especially those classified as “lead-loose.” Store ink buckets tightly sealed to keep creamy consistency, and stir frequently for first-class results.

Use block additives while advocated, and in no way mix incompatible ink brands or chemical compounds. When using puff or uniqueness consequences, confirm with your ink producer that your components paintings with low bleed white and could nonetheless bypass required cure checks.

Routine preservation of your display printing resources—including monitors, squeegees, and dryers—guarantees the consistency and vibrance of your prints, assisting you meet tight cut-off dates and offer the fine results on your customers or customers.