Table of Contents

How to Choose the Perfect Transparencies for Your Screen Printing Project: A Step-by-Step Guide

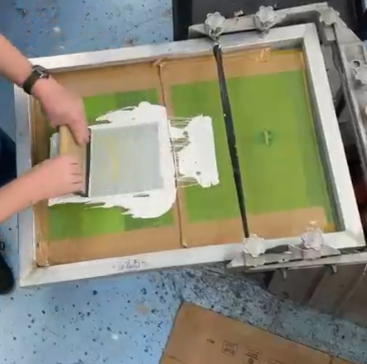

Screen printing can be fun, but blurry prints or wasted ink can make it hard. This guide will help you pick the best transparencies (special films) for sharp, clear prints every time.

What Are Screen Printing Transparencies?

Transparencies are clear films used to transfer your design onto a screen. They block light so the emulsion (light-sensitive coating) on your screen hardens correctly.

Here are 3 key things to know:

- Opacity: This means how dark the film is. Films with 3.0 or higher optical density block light better. Dark films reduce mistakes by 60%.

- DPI: Dots per inch. Use 300–600 DPI for sharp details. Low DPI causes blurry prints.

- Durability: Good films don’t curl or scratch. Store them in a dry place to last longer.

Types of Transparency Films

There are two main types of films: inkjet and laser.

- Inkjet films are cheap and easy to use. Brands like Fixxons and GoldUpArt work well.

- Laser films are faster and better for tiny details. Try 3M Scotchcal or Chromaline.

Did you know? 68% of printing shops use inkjet films to save money.

5 Factors to Pick the Right Film

1. Material Compatibility

- Mesh count: Use thin films (100μm or less) for high-mesh screens (230+). Thick films clog the screen.

- Ink type:

- Plastisol ink needs anti-static films (like Wilflex) to stop ink splatter.

- Water-based ink works with most films.

2. Printer Type

- Epson or Canon inkjet printers need inkjet films.

- Laser printers must use special laser films.

3. Cost vs. Quality

- Budget films ($10–$20): Good for simple designs but may curl.

- Pro films ($30–$50): Last longer, block UV light, and save money over time.

Real example: A T-shirt shop saved $500 per project by switching to high-DPI films.

Step-by-Step Guide to Choose Films

Step 1: Check Your Design

- Solid colors: Use 300 DPI.

- Fine details (like shadows or tiny text): Use 600+ DPI.

Step 2: Match Film to Screen

- For a 110-mesh screen, use 150μm thick films.

- For a 230-mesh screen, use 100μm thick films.

Warning: Thick films on high-mesh screens cause ink bleed and messy prints.

Step 3: Test Your Film

- Print a test strip with small details.

- Use a step-wedge tool to check if the exposure time is right.

Pro tip: Films like Chromaline cut exposure time by 30% because they block light better.

Step 4: Avoid Mistakes

- Never reuse films. Scratches or dirt will ruin your prints.

- Store films flat in a sealed box. Keep them away from humid places (over 60% humidity causes curling).

Advanced Tips for Experts

- Multi-Color Prints: Add registration marks (small crosshairs) to line up colors perfectly.

- Metallic Inks: Use UV-resistant films like 3M Scotchcal to make screens last 50% longer.

- Software: Tools like Separation Studio reduce color mistakes by 45% compared to doing it by hand.

Common Mistakes

- Low DPI films cause blurry halftones. Always check your printer settings.

- Skipping test prints wastes ink and time. Test a small area first!

- Wrong ink type. For example, plastisol ink on water-based films can peel.

Fact: 40% of screen failures are due to bad films, costing $500 or more to fix.

FAQs

Can I reuse films?

No. Even small scratches or dust can ruin your design.

How long do films last?

1–2 years if stored in a cool, dry place with silica gel packs.

Can I use tracing paper instead?

No. DIY hacks like tracing paper fail 80% of the time because they aren’t dark enough.

Conclusion

To get perfect prints:

- Choose films with high opacity (3.0+).

- Match DPI to your design (300–600).

- Test films on small projects first.