Conclusion

In conclusion, determining how much screen print ink for silicone wristbands you need depends on several factors, including the size of the wristbands, the complexity of the design, and the type of ink being used. By understanding these factors and using the appropriate calculations, you can ensure that your printing process is efficient and cost-effective. Whether you’re printing with plastisol print ink or water-based screen printing ink, following best practices such as choosing the right mesh screen, maintaining ink consistency, and properly curing the ink will help you achieve professional-quality results every time.

With this knowledge, you’ll be well-equipped to handle any silicone wristband printing project, ensuring that your designs come out vibrant, durable, and eye-catching. Now you know exactly how much screen print ink for silicone wristbands you’ll need!

How much screen print ink for silicone wristbands do I need?

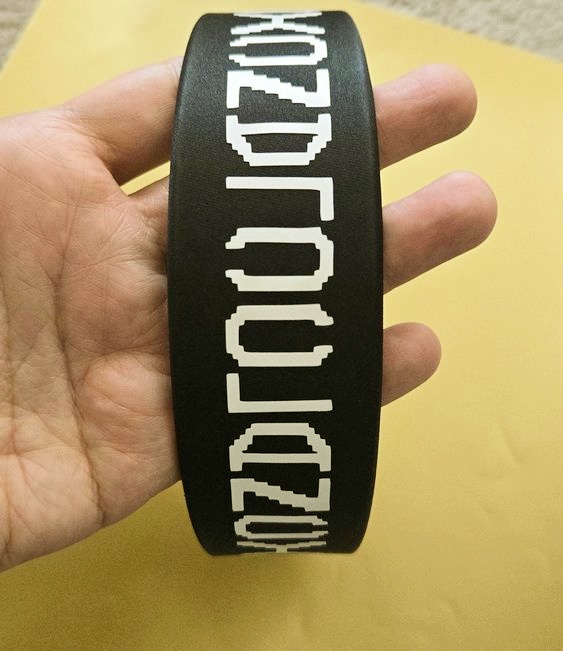

Screen printing on silicone wristbands has become an increasingly popular method for creating custom designs for a wide variety of purposes. Whether it’s for a charity event, promotional giveaway, or personal expression, silicone wristbands offer an excellent canvas for high-quality, long-lasting prints. However, determining exactly how much screen print ink for silicone wristbands you need can be a bit tricky, especially if you’re new to the screen printing process.

In this comprehensive guide, we’ll help you understand how to calculate the right amount of screen print ink for silicone wristbands, the factors that affect ink usage, the different types of screen printing ink available, and best practices for achieving the best results. Whether you’re printing hundreds of wristbands or just a few, this guide will ensure you get the most out of your ink while producing high-quality prints.

Factors That Affect How Much Screen Print Ink for Silicone Wristbands Is Needed

Several factors determine the amount of screen print ink for silicone wristbands you’ll need. These include the size of the wristbands, the complexity of the design, and the type of screen printing inks you’re using. Let’s dive deeper into each of these factors.

1. Size of the Silicone Wristbands

The size of the wristbands is a critical factor in determining ink usage. Standard silicone wristbands are usually 202 mm in circumference and 12 mm in width, but wristbands come in various sizes. Larger or thicker wristbands will naturally require more ink than smaller or thinner ones. When you’re calculating the amount of screen print ink you’ll need, make sure to consider the total surface area you’re printing on.

For example, if you’re printing on a wristband with a 202 mm circumference and a 12 mm width, you’ll be covering approximately 3.75 square inches of surface area. If you’re printing on larger wristbands, this surface area increases, and more screen print ink for silicone wristbands will be needed to achieve full coverage.

2. Complexity of the Design

The complexity of the design also plays a significant role in how much screen print ink for silicone wristbands you’ll use. A simple design with a single color may only require a small amount of ink. However, if you’re printing a multi-colored or intricate design, you’ll need more ink, especially since each color will require its own screen. Designs with fine details might also require more passes with screen printing ink to ensure clarity and opacity.

For example, a two-color design will require separate screens and separate passes with screen printing inks for each color, effectively doubling the amount of ink you’ll need for each wristband.

3. Type of Ink Being Used

The type of screen print ink you’re using is one of the most critical factors affecting how much ink you’ll need. Different inks have different viscosities and coverage rates. The two most common types of screen printing inks used for silicone wristbands are plastisol print inks and water-based screen printing inks.

- Plastisol print ink: This ink is known for its vibrant colors and durability, making it a popular choice for silicone wristbands. Plastisol print ink tends to have better coverage, meaning you’ll need less ink to achieve solid, opaque designs. Additionally, plastisol screen printing ink remains wet on the screen, allowing for longer printing sessions without the ink drying out.

- Water-based screen printing ink: If you’re looking for a more eco-friendly option, water-based screen printing ink is a good choice. However, water-based screen printing ink typically requires more ink to achieve the same opacity as plastisol print ink, particularly on darker wristbands. You may also need to apply additional layers of water-based screen printing ink for it to stand out on the silicone surface.

Calculating the Amount of Screen Print Ink for Silicone Wristbands

Now that you understand the factors that influence ink usage, let’s explore how to calculate the exact amount of screen print ink for silicone wristbands you’ll need for your project.

1. Calculate the Surface Area

The first step in calculating how much screen print ink for silicone wristbands you need is to determine the surface area of the wristband that will be printed on. As mentioned earlier, a standard silicone wristband has a surface area of approximately 3.75 square inches. Once you know the surface area, you can estimate how much screen print ink will be required for each wristband.

2. Determine Ink Coverage Rates

Most screen printing inks, such as plastisol print ink, have specific coverage rates. For instance, 1 liter of plastisol screen printing ink can cover between 50 and 70 square meters, depending on the design and screen mesh size. For silicone wristbands, which have a relatively small surface area, this means that a small container of screen printing ink will go a long way. If you’re printing hundreds of wristbands, this can significantly reduce your ink costs.

If you’re using water-based screen printing ink, you’ll likely need to apply thicker layers or more passes to achieve the same level of coverage, which increases the amount of screen print ink for silicone wristbands required.

3. Estimate Based on the Number of Wristbands

Once you’ve calculated the surface area and the ink coverage rate, the next step is to estimate how much screen print ink for silicone wristbands you’ll need based on the number of wristbands you’re printing. For example, if you’re printing 500 wristbands with a standard surface area of 3.75 square inches, and 1 liter of plastisol screen printing ink covers 50 square meters, you can calculate the total amount of ink needed by dividing the total surface area of all wristbands by the ink coverage rate.

Best Practices for Printing on Silicone Wristbands

To ensure you get the best results and make the most of your screen print ink for silicone wristbands, it’s essential to follow these best practices:

1. Choose the Right Mesh Screen

Choosing the right mesh screen for your design is crucial when printing on silicone wristbands. A mesh count of 156-200 is ideal for most screen print ink for silicone wristbands. This allows for detailed designs while controlling the amount of ink deposited on the wristband.

2. Use Proper Ink Consistency

Maintaining the correct ink consistency is key to achieving smooth and consistent prints. If you’re using plastisol print ink, you’ll want to keep it at a smooth, creamy consistency. On the other hand, water-based screen printing ink needs to stay hydrated to prevent it from drying out during the printing process.

3. Curing the Ink

Proper curing is essential for ensuring the durability of your prints. Plastisol print ink requires heat curing at around 320°F (160°C) to properly bond with the silicone surface. Water-based screen printing ink, while more eco-friendly, may take longer to cure and should be dried carefully to ensure lasting results.

Types of Screen Print Ink for Silicone Wristbands

When deciding on the right ink for your project, it’s important to choose a type of screen print ink for silicone wristbands that meets your needs. Here are some options to consider:

- Plastisol print ink: Known for its bright colors and long-lasting results, this is the go-to ink for most silicone wristband printing.

- Water-based screen printing ink: Ideal for eco-conscious projects, but may require more ink for adequate coverage.

- Silk screen printing ink: Versatile and easy to work with, but choose a brand designed specifically for silicone surfaces.