This guide introduces an environmentally pleasant technique for generating plastisol warmness transfers using SHALITEINK’s low-temperature treatment inks.

It is meant for garb manufacturers, print studios, and creators who intention to enhance production efficiency even as reducing environmental impact.

Why Choose SHALITEINK Heat Transfers

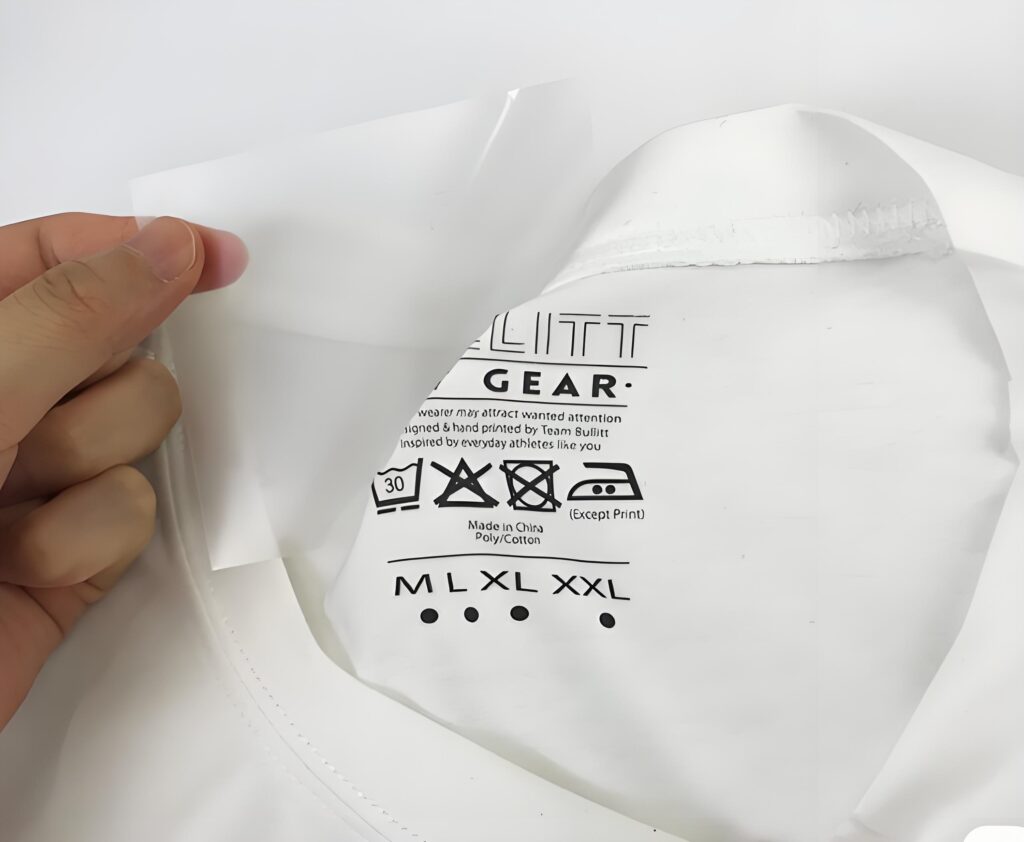

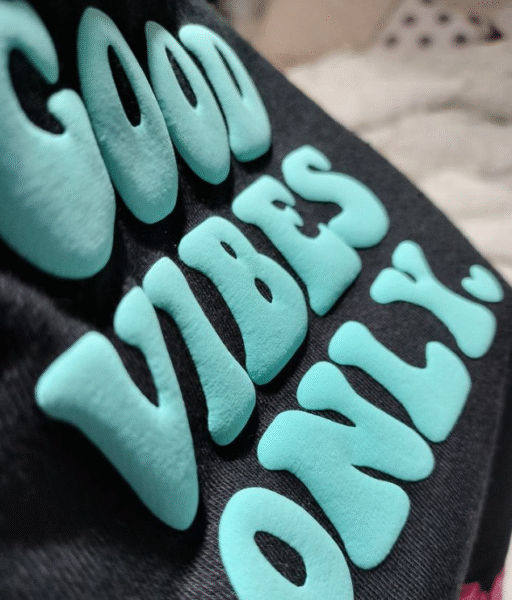

Plastisol heat transfers are a versatile solution widely used in the garment decoration industry—for neck labels, live printing, and small custom runs. SHALITEINK’s low-cure plastisol ink delivers excellent print quality while supporting sustainable production practices.

Environmental and Technical Advantages:

Low curing temperature (round 127°C / 260°F) appreciably reduces energy consumption

Minimal paper deformation all through curing, decreasing fabric waste

Non-clogging formula complements display balance and minimizes downtime

High-opacity pigments require fewer passes, saving ink

Free from heavy metals and compliant with international safety standards

Required Materials

Heat transfer paper

Adhesive powder

SHALITEINK low-treatment plastisol ink

Mesh display and printing body

Squeegee

Manual or automated screen printing press

Conveyor dryer

Heat press

Tape, plastic packing containers, and other preferred printing tools

Whenever possible, supply materials from licensed sustainable providers to assisteco-conscious production goals.

Process Overview

Pre-Drying the Transfer Paper

Before printing, skip the switch paper thru a conveyor dryer at low warmth to take away ambient moisture. A dry and flat floor improves ink usual performance and minimizes warping during curing.

Screen Printing

Apply balanced squeegee strain to make certain even insurance. Avoid overly thick ink layers, which may cause picture distortion in some unspecified time in the future of heat urgent. SHALITEINK’s high-opacity method lets in many designs to be found out in a single bypass.

Three. Adhesive Powder Application

Immediately after printing, region the sheet proper into a field of adhesive powder. Evenly coat the published surface, then gently shake off any extra. Collect and reuse excess powder to limit waste.

- Gel Curing (Partial Cure)

Use a conveyor dryer to warmness the ink till the surface is dry to touch—do no longer fully therapy the ink.

SHALITEINK’s formula gels efficiently at around 93°C (200°F), reducing energy use, speeding up production, and preserving paper integrity.

5. Heat Pressing

Typical warmness press settings (may additionally range):

Temperature: 177°C (350°F)

Time: 10 seconds

Pressure: Medium to firm (four–five)

Place the transfer face down onto the garment.

For warm peel, get rid of the backing paper right now after pressing.

For cold peel, allow the garment to chill completely earlier than peeling.

Conclusion

SHALITEINK heat transfers offer a reliable and sustainable alternative for transfer manufacturing. Its low-temperature cure system not most effective improves workflow performance however also reduces power intake, ink waste, and material loss.

As the call for for accountable manufacturing continues to upward push, SHALITEINK empowers each small studios and big-scale operations to fulfill excessive high-quality requirements even as minimizing environmental effect.