Plastisol ink is a popular choice in the screen printing industry due to its durability and vibrant colors. However, mistakes happen, and sometimes you need to remove plastisol ink from your fabric. One of the most effective tools for this job is a spot cleaning gun. This article will guide you through the process of using a spot cleaning gun to remove plastisol ink, as well as provide essential tips to ensure the best results.

Start Your Jobs

Before diving into the spot cleaning process, it’s important to start your printing jobs correctly to minimize the need for ink removal. Proper setup and handling of your screens, squeegees, and inks can significantly reduce the likelihood of errors. Always ensure your screens are properly aligned, your squeegees are clean, and your plastisol ink is applied evenly. This not only saves time but also reduces the amount of ink wasted during the process.

Taking the time to prepare your workspace and tools before starting your print jobs can prevent mishaps that require the use of a spot cleaning gun. However, when mistakes do occur, it’s good to know that a reliable plastisol ink remover is available.

Heads Up

Before using a spot cleaning gun, it’s crucial to understand that these tools are powerful and require careful handling. A spot cleaning gun uses a combination of air pressure and cleaning solvent to remove ink from fabric, making it an effective but potentially hazardous tool if not used properly.

The solvent used in a spot cleaning gun, commonly referred to as a plastisol ink remover, can be strong and may emit fumes that are harmful if inhaled. Always work in a well-ventilated area and consider wearing protective gear such as gloves and a mask to protect yourself from exposure to the solvent.

Additionally, it’s important to test the solvent on a small, inconspicuous area of the fabric before proceeding with the full ink removal. This helps ensure that the solvent won’t damage the fabric or cause discoloration.

Spot Clean

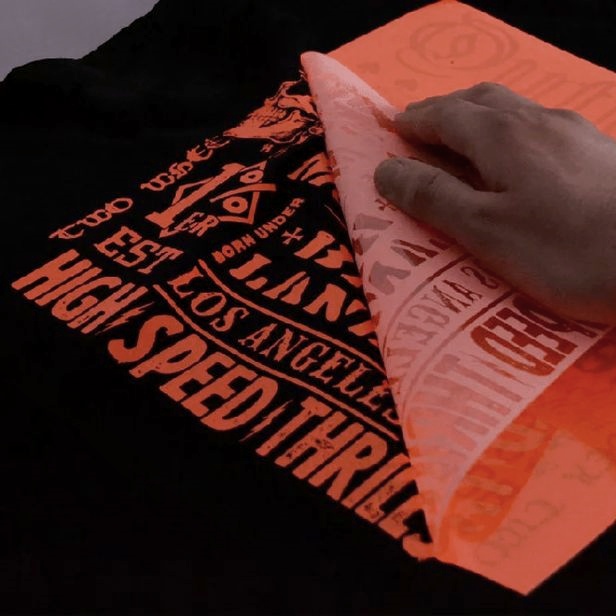

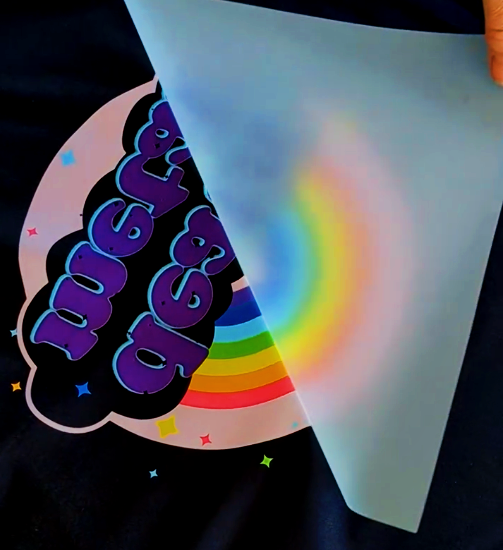

Spot cleaning is an effective method for removing plastisol ink from garments without affecting the entire design. Whether it’s a small smudge or an unwanted ink spot, a spot cleaning gun combined with plastisol ink remover can help you save the garment and maintain the quality of your print.

To begin the spot cleaning process, make sure the fabric is laid flat on a clean, stable surface. This allows you to focus on the area that needs cleaning without worrying about additional ink transfer. Once your workspace is set up, you’re ready to move on to the actual cleaning process.

The Spot Cleaning Process

The spot cleaning process using a spot cleaning gun is relatively straightforward but requires attention to detail to achieve the best results. Here’s a step-by-step guide:

- Prepare the Spot Cleaning Gun: Fill the spot cleaning gun’s reservoir with the appropriate plastisol ink remover. Make sure the gun is properly assembled and that all parts are securely in place.

- Target the Area: Hold the fabric taut over the spot that needs cleaning. Position the spot cleaning gun nozzle close to the ink spot but not touching the fabric. A distance of about 1-2 inches is typically effective.

- Apply the Cleaner: Gently squeeze the trigger to release the plastisol ink remover onto the ink spot. The combination of solvent and air pressure will break down the plastisol ink, lifting it from the fabric. Be cautious not to oversaturate the area, as this can spread the ink or damage the fabric.

- Blot the Area: After applying the cleaner, use a clean, dry cloth to blot the area. This helps absorb the solvent and ink residue. Avoid rubbing, as this can push the ink deeper into the fabric fibers.

- Repeat as Necessary: Depending on the severity of the ink spot, you may need to repeat the process multiple times. Each application should reduce the visibility of the ink until it is completely removed.

- Rinse and Dry: Once the ink is removed, rinse the area with a small amount of water to remove any remaining solvent. Then, allow the fabric to air dry completely before proceeding with any further printing or curing.

It’s Smart to Vent

As mentioned earlier, ventilation is key when using a spot cleaning gun with plastisol ink remover. The solvent can emit strong fumes that may be harmful if inhaled in large quantities. To ensure a safe working environment, make sure you are in a well-ventilated area. If possible, work near an open window or use an exhaust fan to help dissipate the fumes.

In addition to ventilation, consider using a respirator mask designed to filter out solvent fumes. This added layer of protection can prevent respiratory irritation and other potential health issues associated with prolonged exposure to solvent fumes.

Common Alternatives to Plastisol Ink

While plastisol ink is widely used in screen printing, there are alternative inks that offer different advantages and may be easier to clean if mistakes occur. Here are a few alternatives to consider:

Water-Based Inks

Water-based inks are eco-friendly and provide a softer hand-feel compared to plastisol inks. They are easier to clean from screens and fabrics with water, making them a good option for those looking to minimize solvent use.

Discharge Inks

Discharge inks work by removing the dye from the fabric, leaving a soft print that is part of the material itself. These inks are ideal for creating vintage or distressed looks, and they are easier to clean from screens than plastisol inks.

Hybrid Inks

Hybrid inks combine the benefits of plastisol and water-based inks. They offer the vibrant colors and durability of plastisol inks but with a softer feel and easier cleanup similar to water-based inks.

Conclusion

Using a spot cleaning gun with plastisol ink remover is an effective way to correct mistakes in plastisol ink printing. By following the proper procedures and taking necessary precautions, you can successfully remove unwanted ink spots without damaging the fabric. Remember to start your printing jobs with the right setup to minimize errors, and always work in a well-ventilated area when using solvents.

While plastisol ink remains a popular choice for screen printing due to its durability and versatility, understanding the cleaning process and exploring alternatives can help you make informed decisions for your printing projects. Whether you stick with plastisol ink or experiment with other ink types, having the right tools and knowledge at your disposal will ensure the best results every time.