Summary: The Keys to Successful High Density Plastisol Ink Printing

- High density plastisol ink is all approximately ambitious, three-D texture and crisp, sharp edges to your prints.

- The technique requires thick stencils, low mesh monitors, and careful layering of excessive-viscosity ink.

- Choose robust fabric like cotton, polyester, or blends for the most durable, appealing effects.

- Cure your ink thoroughly—thick layers want extra warmth to retain their stack and avoid cracks or smears.

- Always check mesh, emulsion, and curing instances earlier than full production runs.

- Try exclusive finishes—glossy, matte, metallic, or foil—for genuinely unique, excessive-effect consequences.

- Mastering high density screen printing manner you’ll produce garb that sticks out, stacks up, and retains its dimension and facet over the years.

Ready to wow your customers or degree up your very own designs? High-density plastisol ink gives printers the energy to print with dimension, part, and unforgettable style

Create Jaw-Dropping 3D Prints: Your Guide to High Density Plastisol Ink in Screen Printing

Are you prepared to take your display printing to the following stage with eye-popping 3-d designs and crisp, raised textures? High density plastisol ink printing grants bold, tactile effects that make apparel stand proud of the crowd. This article is a should-study for all of us inside the printing industry seeking to upload that unmistakable aspect to their t-shirt, hoodie, or strong point garment tasks. Discover the secrets and techniques behind this superb approach—from the thick layers that stack up off the cloth to the pointy edges that make designs really pop. Whether you’re a pro printer or just getting started out, you’ll locate actionable suggestions, expert insights, and clear answers to all your excessive-density printing questions. Let’s dive in!

Article Outline

- What Makes High Density Ink Printing So Special?

- How Does High Density Screen Printing Work?

- What Is High Density Plastisol Ink?

- Why Use High-Density Inks Instead of Puff Inks?

- Which Fabrics Are Best for High Density Prints?

- How Do You Build a Thick Stencil for Crisp, Raised Designs?

- What Is the Best Mesh and Emulsion Setup for High Density Printing?

- How Do You Cure High Density Plastisol Ink for Maximum Durability?

- Troubleshooting: Why Did My High Density Ink Print Crack or Smear?

- Unique Effects: Foil, Metallic, and Other 3D Texture Options

1.What Makes High Density Ink Printing So Special?

High density ink printing is all approximately including dimensional wow to your work. Traditional display screen printing lays down a flat layer of ink, but high-density techniques deposit thick layers that create a dramatic 3-dimensional, raised effect. The ink literally stands up off the fabric, giving your design a texture you can see and sense. This form of print doesn’t just seize the attention; it demands attention with its crisp, sharp edges and strong stack of ink.

Designs that stand out, quite literally, are ideal for making emblems, textual content, or artwork that needs an side in each the literal and figurative feel. High density prints are a extraordinary match for branded clothing, streetwear, and products aiming to make an on the spot impression.

What makes it greater special? That unmistakable tactile sensation while you run your finger over the layers of thick ink. Add within the capacity to supply dramatic, unique effects with distinct finishes—like sleek, matte, or even steel—and also you’ve got a tool that pushes your innovative boundaries in addition than widespread ink can.

2.How Does High Density Screen Printing Work?

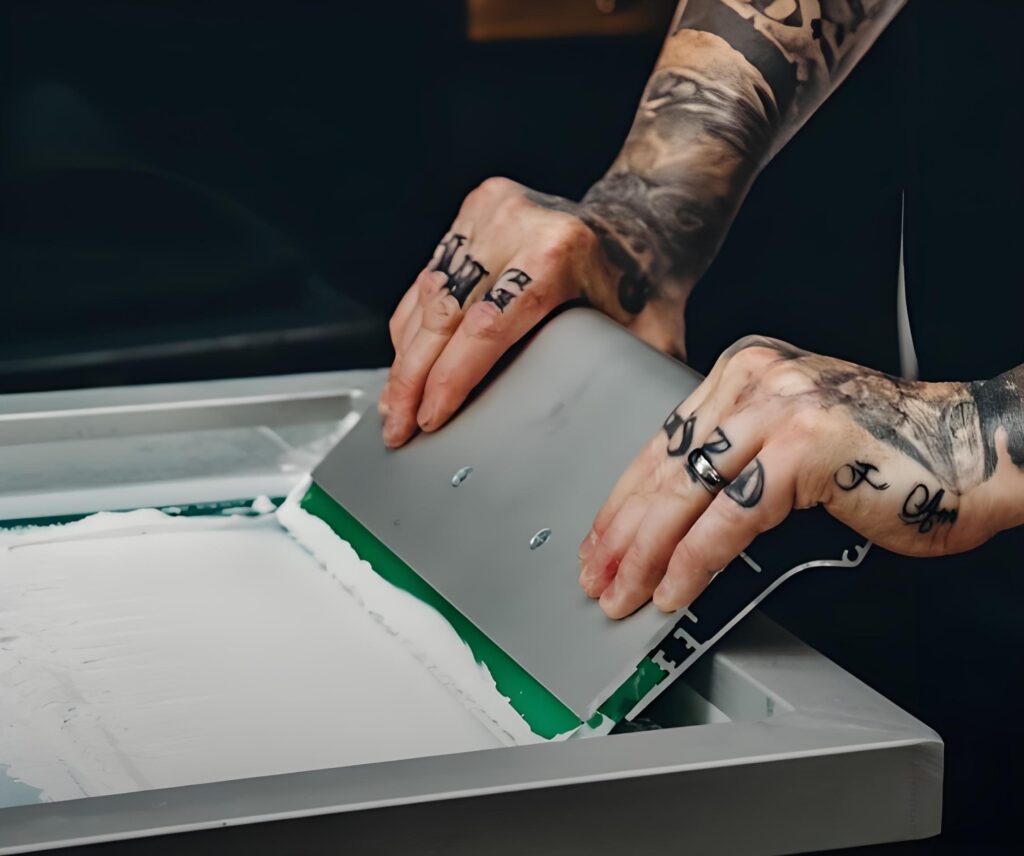

High-density display screen printing builds on the conventional display screen printing method you could already know—however with some key adjustments. The mystery lies in layering: to acquire the ones brilliant 3-d effects, printers use more than one layers of ink, pushing a excessive viscosity plastisol via a completely thick stencil onto the garment. The end result is a stack of ink that’s extensively thicker than a wellknown print.

This printing process requires each specialised gear and a bit more persistence than a primary print. The thick ink and stencil combination lays down a heavy deposit in keeping with inch, letting you create extraordinarily sharp edges and complex textures.

Achieving constant raised effect designs comes down to exercise and precision. Fine details rely upon properly-organized stencils, careful coating, and dialing inside the proper squeegee pressure. But believe us—the bendy, long lasting, tremendous final result is well worth the effort.

3.What Is High Density Plastisol Ink?

High density plastisol ink is a type of ink used mainly for developing thick, raised prints in display printing. This excessive-viscosity plastisol flows slowly, taking into consideration specific manipulate and sharp, mentioned edges in your very last print. Because this ink is thicker than trendy plastisol inks, it’s the high-quality match while your aim is an unmistakable dimensional look in preference to a smooth hand feel.

The mystery component is its chemistry: plastisol ink is fabricated from PVC debris in a plasticizer, which means it gained’t air-dry. Instead, it wishes to be cured underneath warmth to absolutely set on the material. Unlike water-based totally inks, high density plastisol ink keeps its form and sharpness after curing, so your designs continue to be crisp, stack nicely, and don’t smear or get blurry with washing.

The ink may be used on a extensive range of clothes and offers specific finishes—sleek, matte, and even opaque in case you preference. With alternatives like HD black and high-density white, as well as special blends for poly and cotton, excessive density plastisol ink truely unlocks your creativity in clothing ornament.

4.Why Use High-Density Inks Instead of Puff Inks?

You is probably thinking: why go for excessive-density inks when puff inks additionally create a raised effect? While each techniques create a 3D look, the information set them aside.

Puff inks make bigger at some stage in the cure technique, giving a softer, spherical or “pillowy” experience and a less specific side. High-density inks, by way of assessment, produce sharp edges and the capacity to build extremely crisp, geometric layers. This way if your layout calls for sharp lines, stacked effects, or a textured impact with most size and sturdiness, excessive-density inks are the way to go.

High density techniques provide the nice fit for programs wherein the sharpness of the layout and the sturdiness of the edge are non-negotiable—suppose formidable typography, emblems, or architectural artwork on clothes, wherein the ones tactile ridges have to remain crisp and maintain their side over many washes24.

5.Which Fabrics Are Best for High Density Prints?

Selecting the right cloth can make or break your high density layout. Since the ink is thick and heavy, it adheres excellent to strong, easy surfaces. Cotton is a classic desire because it absorbs plastisol ink properly and facilitates retain the raised effect after curing. Apparel made from polyester or combined fabrics like poly/cotton blends also can paintings nicely—all you need is the proper ink and therapy settings2.

What approximately strong point fabrics? High density ink produces mainly high-quality outcomes on heavyweight t-shirts, hoodies, and sweatshirts. For lighter garments, extra care need to be taken to prevent bleed-thru or undesirable texture distortion.

In all instances, it’s crucial to test your ink and printing manner on the cloth earlier than launching full-scale production. Mixing and matching ink blends (like the usage of a discounted tack and increased drift system for polyester) allows you get the quality viable adhesion and high-density effect to your precise garment.

6.How Do You Build a Thick Stencil for Crisp, Raised Designs?

The thick stencil is the unsung hero of high-density display screen printing. To deposit multiple layers of ink and create those famous sharp edges, you’ll want a stencil that’s tons thicker than what you’d use for traditional prints.

Start with a low mesh depend display screen—typically one hundred ten mesh in line with inch or even decrease—which permits heavy deposits of ink to pass thru. Next, coat your screen with numerous layers of emulsion, constructing up the thickness to healthy your target dimension. Some printers favor to use specialty high-density emulsions that harden to a more height and support the load of the thick ink deposit.

The result? An fantastically precise, high-remedy stencil that guarantees each skip of your squeegee pushes the right quantity of ink in exactly the proper place. If you need designs with extraordinarily sharp edges, making an investment time in making a thick, properly-organized stencil will pay off whenever

7.What Is the Best Mesh and Emulsion Setup for High Density Printing?

Mesh and emulsion picks play a large role inside the achievement of your high density undertaking. For mesh, choose a low count: the less threads consistent with inch, the bigger the “windows” for thick ink to flow via—assume 80-a hundred and ten mesh in keeping with inch as a baseline.

When it comes to emulsion, double or maybe triple coat each facet of your screen to accumulate the required thickness. Some producers offer specialty HD emulsions (like Lancer) designed for extreme builds, or you can experiment with stacking a couple of coats together with your existing product.

The secret’s uniformity across the stencil—whether aiming for a single thick layer or printing multiple stacks for added height, consistency is crucial for achieving that clean, awesome aspect you want. The thicker your emulsion layer and the decrease your mesh count, the more dramatic your 3-d impact.

8.How Do You Cure High Density Plastisol Ink for Maximum Durability?

Curing is what transforms your sticky, high-density print right into a long lasting, wash-resistant masterpiece. High density plastisol ink should attain a specific temperature—typically around 320°F (160°C)—to well fuse with the cloth. Since the ink layer is thicker here than with popular screen printing, it’s vital the heat penetrates all the way thru.

Use a conveyor dryer for first-rate consequences, allowing the fabric and ink masses of time to treatment lightly. If you’re curing a couple of layers or the use of distinctiveness outcomes like foil or metal debris, growth live time to ensure complete fusion.

A poorly cured print can crack, peel, or fail to preserve its size. Check your completed work with the aid of stretching the garment: the ink should flex with out breaking, and the layers need to remain stacked firmly with a crisp texture and sharp edges intact.

9.Troubleshooting: Why Did My High Density Ink Print Crack or Smear?

Nothing’s greater frustrating than seeing your high-density layout crack, smear, or fail to stack nicely. Here’s what to observe for:

- Under-curing: The most common perpetrator. Thick ink needs greater warmth—so make certain your curing equipment is as much as the assignment.

- Incorrect stencil peak: If your emulsion layer isn’t thick enough, you gained’t get that three-dimensional stack; too thick, and detail might be misplaced.

- Squeegee pressure: Too an awful lot strain pushes ink past the supposed edge, inflicting loss of detail or smearing; too little, and the deposit is choppy.

- Wrong mesh or ink components: Using too high-quality a mesh, or widespread plastisol inks rather than high viscosity sorts, can restriction your results and reason issues with adhesion or crispness.

To remedy, dial in your mesh, emulsion, and squeegee setup, and usually perform a take a look at treatment before launching a complete print run. Your print save’s consistency depends on it.

10.Unique Effects: Foil, Metallic, and Other three-D Texture Options

The amusing doesn’t prevent at fundamental excessive-density ink! You can experiment with various specific outcomes—like metal excessive-density inks, foil overlays, or gel inks—to push the creative envelope. Foil can be implemented to the raised portions of the design, developing high contrast shine and additional wow issue.

You may also mix in sleek or matte additives into your plastisol, or play with opaque or semi-obvious ink layers for particular optical intensity. For greater texture, combination in debris or forte effects that make every garment clearly one-of-a-kind.

There’s no limit to what you can obtain—the best rule is to test very well. Different finishes, particle sizes, and overlays all reply otherwise to heat, fabric, and thickness, so permit experimentation pressure your creative method.