Discover how to use clear vinyl for screen printing emulsion, tips for vinyl stencils, and the best materials for flawless prints.

1. What Emulsion Should I Use for Screen Printing?

When it comes to screen printing, choosing the right emulsion is crucial for achieving high-quality results. Emulsion acts as a stencil on the screen, allowing ink to pass through only the desired areas. For clear vinyl for screen printing emulsion, a dual-cure or photopolymer emulsion is often recommended. These emulsions are versatile, durable, and work well with both water-based and plastisol inks.

If you’re using clear vinyl for screen printing emulsion, ensure the emulsion is compatible with the vinyl material. Some emulsions are specifically designed for intricate designs and fine details, making them ideal for projects involving vinyl stencils. Always follow the manufacturer’s instructions for coating, exposing, and washing out the emulsion to avoid under- or over-exposure.

2. How to Use Vinyl Stencils for Screen Printing

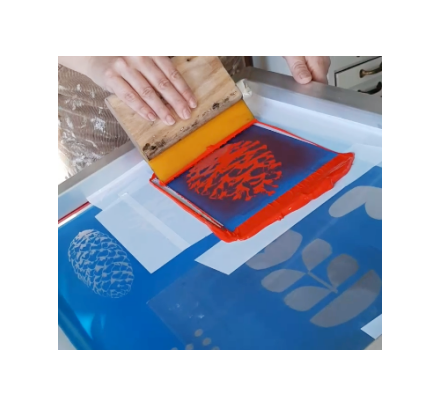

Vinyl stencils are a popular choice for screen printing due to their precision and ease of use. Here’s a step-by-step guide to using vinyl stencils:

- Design Your Stencil: Use a cutting machine or craft knife to create your design on clear vinyl.

- Prepare the Screen: Apply a layer of clear vinyl for screen printing emulsion to the screen and let it dry.

- Apply the Stencil: Carefully place the vinyl stencil onto the emulsion-coated screen, ensuring it adheres smoothly.

- Expose the Screen: Use a UV light source to expose the screen, hardening the emulsion around the stencil.

- Wash Out the Design: Rinse the screen to remove the unexposed emulsion, leaving your design ready for printing.

Vinyl stencils are perfect for beginners and professionals alike, offering clean lines and minimal setup time.

3. Can You Use Any Transparency Paper for Screen Printing?

Transparency paper is essential for creating screens, but not all transparency papers are created equal. For screen printing, you need high-quality, clear transparency paper that is compatible with your printer and emulsion.

Low-quality transparency paper can result in blurry designs or incomplete exposure, leading to poor print quality. When using clear vinyl for screen printing emulsion, pair it with professional-grade transparency paper to ensure crisp, accurate designs. Always check the opacity of the paper—thicker, more opaque papers block UV light better, resulting in cleaner stencils.

4. Can I Use Vinyl for Screen Printing?

Yes, you can absolutely use vinyl for screen printing! Vinyl is a versatile material that works well for creating stencils and even direct printing on certain surfaces. When paired with clear vinyl for screen printing emulsion, vinyl stencils offer precision and durability, making them ideal for intricate designs and multi-color prints.

Vinyl is also a great alternative to traditional screen printing methods for small projects or one-off designs. However, for large-scale production, traditional screen printing with emulsion may be more efficient.

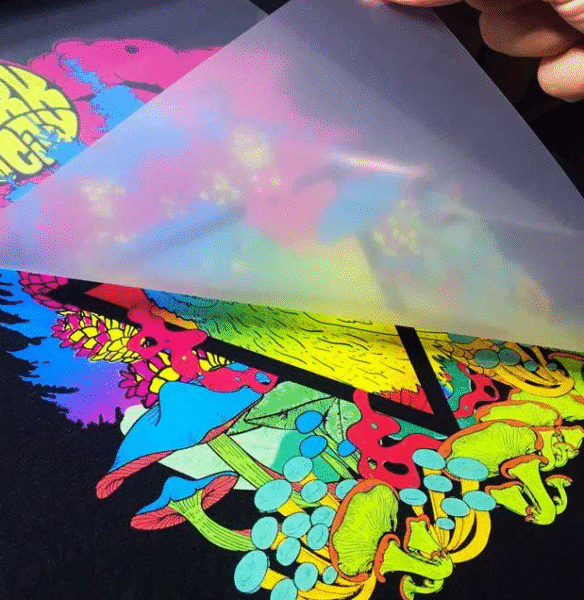

5. How Do I Print on Clear Transparent Paper?

Printing on clear transparent paper requires a few specific steps to ensure success:

- Choose the Right Paper: Use high-quality, inkjet or laser-compatible transparency paper.

- Adjust Printer Settings: Set your printer to the highest quality setting and select the appropriate paper type (e.g., “transparency” or “glossy”).

- Print a Test Page: Always print a test page to check for smudging or alignment issues.

- Handle with Care: Allow the ink to dry completely before handling to avoid smudges.

Clear transparent paper is perfect for creating screens with clear vinyl for screen printing emulsion, as it allows for precise exposure and sharp designs.

6. What Paper Is Best for Screen Printing?

The best paper for screen printing depends on your project. For creating screens, clear transparency paper is the top choice due to its clarity and compatibility with emulsion. For printing final designs, consider the following:

- Transfer Paper: Ideal for heat-press applications.

- Kraft Paper: Great for protecting screens during storage.

- Parchment Paper: Useful for protecting designs during the curing process.

When using clear vinyl for screen printing emulsion, always pair it with high-quality transparency paper to ensure the best results.

Conclusion

Screen printing is a versatile and rewarding craft, and using the right materials is key to success. Whether you’re working with clear vinyl for screen printing emulsion, vinyl stencils, or transparency paper, each component plays a vital role in creating flawless prints. By following the tips and techniques outlined in this guide, you’ll be well on your way to mastering the art of screen printing.