Bullet Point Summary: Key Takeaways on White Plastisol Ink Screen Printing

- White plastisol ink is important for bold, opaque prints—essential for display screen printing on darkish cotton, poly, and blends.

- Proper cure temperature is vital: under or over-cure leads to cracks, failed wash assessments, or scorch.

- Always fit your ink type—fashionable, low remedy, or low bleed—to the shirt material for excellent consequences.

- Thick, creamy, easy to print white plastisol inks like Rutland’s ultimate alternatives supply first rate coverage with a soft hand and brilliant finish.

- Avoid ink waste by buying the proper length: quarts, gallon, or five gallon containers in your production needs.

- Use right mesh count number, squeegee method, and screen coating thickness to control ink deposit and maximize opacity.

- Troubleshoot issues like dye migration, cracks, and fading by running flash assessments, adjusting dryer settings, and doing wash exams.

- Mixing systems from pinnacle manufacturers assist you to first-class-song ink for custom prints with out sacrificing performance.

- Store your ink in a cool, sealed location to keep creamy consistency and printability.

- Consistency in manner—from blending to curing—guarantees each shirt grants top rate, long lasting effects.

By making use of those standards and exceptional practices, you’ll transform your white plastisol display screen printing into a dependable procedure that promises show-stopping prints whenever

Can you mix water with plastisol white ink?

Are you trying to attain crisp, vibrant white prints that pop off any shirt? White plastisol ink is each display screen printer’s workhorse for bold, opaque prints on darkish clothes, particularly cotton and polyester blends. Whether you run a bustling save or dabble in DIY prints at domestic, understanding white plastisol ink—its residences, how to print, therapy, and handle commonplace pitfalls—transforms normal T-shirts into eye-grabbing merch. This blog put up dives deep into white plastisol ink: from choosing and combining ink to curing and troubleshooting for the brightest, most long lasting white displays you’ve ever published. Stick round, because this text hands you with realistic, actual-global strategies that make all the distinction!

Article Outline

- What Is White Plastisol Ink? (Ink, Print, Opaque)

- Why Is White Plastisol Ink Essential in Screen Printing?

- How Do Temperature and Cure Affect White Prints?

- What’s the Best Way to Print with White Plastisol Ink?

- Gallons, Quarts, or 5 Gallon—How Much Ink Do You Need?

- Cotton, Poly, or Blends: Which Fabrics Work Best with White Plastisol?

- How Low Cure and Low Bleed White Inks Fight Dye Migration

- Mixing and Using Rutland and Premier Inks

- How to Achieve Maximum Opacity and Coverage on Shirts

- Top Troubleshooting Tips: Cracks, Bleeding, Scorch, and Wash Durability

1.What Is White Plastisol Ink? (Ink, Print, Opaque)

White plastisol ink is a creamy, opaque ink designed specifically for display printing. Unlike water-primarily based inks, plastisol inks are fabricated from PVC debris suspended in a plasticizer, which only treatment and grow to be stable at excessive temperatures. Because of its composition, white plastisol is famous amongst display printers aiming for a bold, vibrant print that sits proudly atop clothes, with robust opacity even on dark fabric.

In terms of use, white plastisol ink is often chosen whilst you need a excellent opaque base for vibrant prints, or a stand-on my own white design that doesn’t lose electricity on black, navy, or coloured shirts. This makes it a staple within the toolkit of every printer seeking out high-insurance “white screen” effects. Besides coverage, it’s recognized for generating a gentle hand (the feel of the print on the cloth), advanced wash durability, and a bendy, long-lasting finish.

2.Why Is White Plastisol Ink Essential in Screen Printing?

Without a strong white plastisol ink, display screen printers face dwindled graphics, vulnerable “pop” on darker shirts, and even dye migration issues. White plastisol ink acts as a foundation, or underbase, for most display screen print designs—especially whilst printing lighter hues on dark material. The opacity of white plastisol ink blocks the underlying blouse color, which lets in for genuinely vibrant and desirable designs.

Screen printing plastisol is advanced to water-primarily based ink in terms of ease-of-use and print insurance. Because plastisol inks don’t “dry” until they therapy in a dryer, you could take your time putting in place, solving errors, or making a couple of passes to get that perfect ink deposit. Simply placed, if you print shirts on a regular foundation, growing mastery over white plastisol ink will liberate new degrees of great and creativity to your save.

3.How Do Temperature and Cure Affect White Prints?

The unmarried most critical element in a lasting print is curing your ink at the correct temperature. Plastisol display screen printing calls for white plastisol inks to be cured at precise temperatures, normally round 320°F (a hundred and sixty°C). If you under-treatment, the ink gained’t bond with the fabric fibers properly, leading to cracking, wash screw ups, or even “ghosting” in which the garment dye bleeds into the ink.

However, over-curing can scorch the cloth or motive brittle prints. Monitoring temperature and adjusting dryer live time ensures a right treatment—mainly with thicker ink layers on fleece or heavier shirts. Many top class white plastisol inks, inclusive of low cure and occasional temperature therapy products, allow for curing at even lower temperatures (round 270°F or 132°C), which reduces the hazard of dye migration or cloth sizzling whilst nevertheless turning in an opaque, flexible result.

4.What’s the Best Way to Print with White Plastisol Ink?

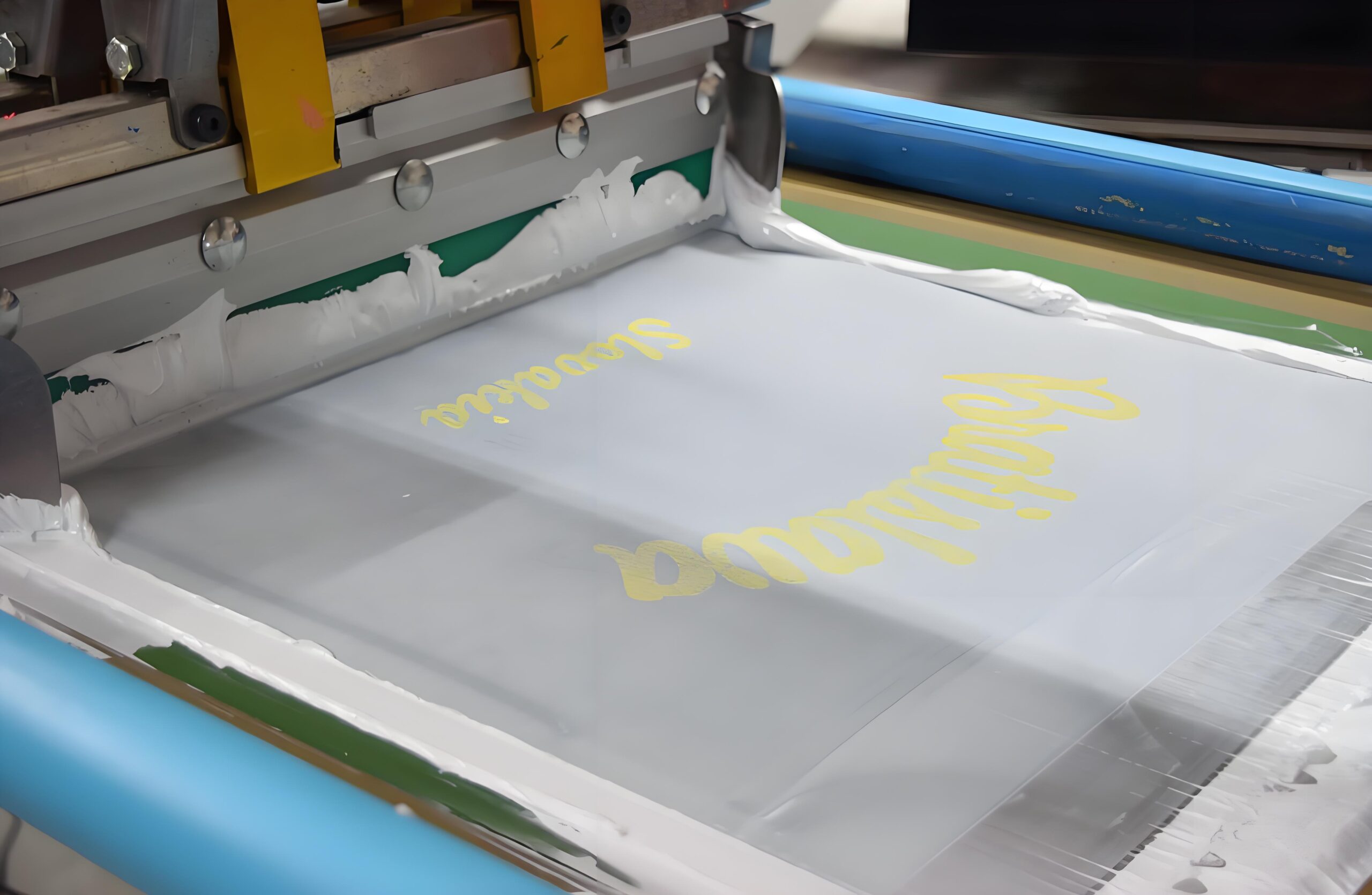

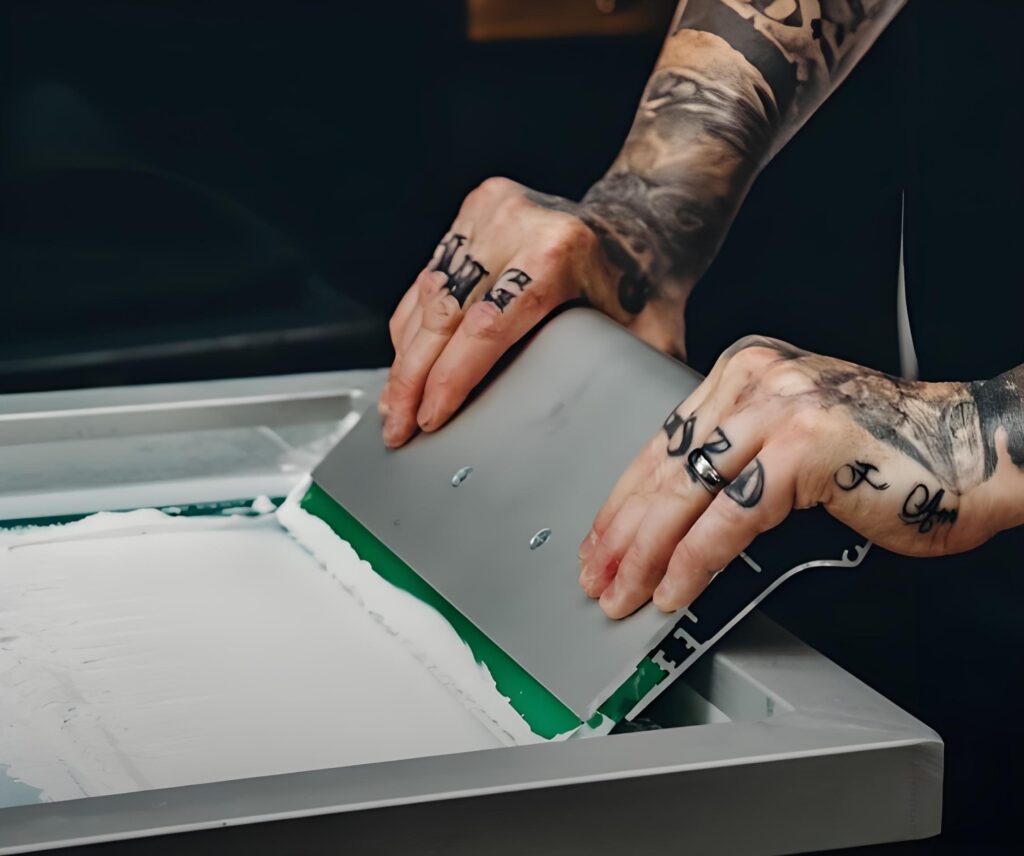

Great white prints begin with the right tools and technique. Use a mesh count number that suits the ink thickness and cloth: typically, one hundred ten-one hundred fifty five mesh works first-rate for opaque white plastisol ink on popular shirts. Lay down an excellent, formidable layer of ink—don’t skimp! Consider double-stroking or the use of a “flash” between coat packages to construct opacity with out immoderate ink build-up.

When you print, manipulate your squeegee perspective and stress for constant ink deposit. An clean to paintings creamy ink spreads evenly, making sure crisp edges and suitable insurance. After every print, run a brief wash check to confirm wash durability. For darkish shirts, laying a mild “ghost gray” pass before the white plastisol base can improve brightness in case your ink isn’t incredibly opaque.

5.Gallons, Quarts, or 5 Gallon—How Much Ink Do You Need?

Professional printers frequently buy white plastisol ink in lots of sizes primarily based on their production extent—quarts for small runs, gallons for regular jobs, and five gallon buckets for excessive-quantity shops. Knowing how an lousy lot ink to shop for avoids waste and saves money. One gallon of high-opacity white plastisol can typically print masses of shirts, however actual coverage relies upon at the print period, ink deposit method, and whether you’re printing single or double passes.

Investing in huge packing containers of optimal inks like Rutland or one of a kind pinnacle rate manufacturers can pay off for busy stores. Remember to keep your ink sealed and away from warm temperature to keep it creamy and smooth to print, whether or not you’re the usage of a gallon or dipping proper into a five gallon bucket.

6.Cotton, Poly, or Blends: Which Fabrics Work Best with White Plastisol?

White plastisol ink shines brightest on a hundred% cotton garments. Cotton’s absorbency holds the ink properly and allows obtain a tender hand that customers love. However, polyester and poly-cotton blends gift additional demanding situations. Dyes in polyester fibers often migrate, causing unwanted colour bleeding into white prints, especially at higher treatment temperatures. That’s why low bleed and coffee therapy white plastisol inks are crucial for poly and blended material display screen printing plastisol applications.

To lessen dye migration, use particularly formulated low bleed ink for polyester. Choosing the proper white plastisol ink could make the difference between a crisp, bold print and one that appears washed out or off-shade after just one wash. If in doubt, always run a check print and wash take a look at earlier than committing to a huge print run.

7.How Low Cure and Low Bleed White Inks Fight Dye Migration

Dye migration takes place when the shirt’s fabric dye rises into the ink in the course of curing—maximum not unusual with polyester and dark blends. To prevent this, display screen printers use low remedy and low temperature therapy white plastisol inks. These treatment at lower temperatures (as little as 270°F), minimizing the risk of dye migration and burning (scorch) sensitive polyester blends.

Low bleed ink formulations are engineered with premium substances that block dye migration, preventing purple or yellow “ghosting” in its tracks. This guarantees the brightness of your white display screen stays formidable, wash after wash. Consider manufacturers like Rutland for their high performance low bleed white inks, which might be creamy, smooth to print, and exceptionally opaque, sealing the deal for both cotton and intricate poly garments.

8.Mixing and Using Rutland and Premier Inks

Sometimes you need to custom-blend your ink for a unique finish, hand feel, or to accommodate particular shirt sorts. Leading manufacturers like Rutland offer a mixing system for white plastisol display printing, in which you may create custom colorations or alter viscosity and remedy temperature. When mixing, usually stick with compatible plastisol ink designed for the equal treatment temp and fiber type—don’t mix water-base with plastisol, or low remedy ink with preferred cure except the manufacturer recommends it.

Premier and Rutland inks are regarded for being creamy and easy to work, with excessive opacity—meaning you operate much less ink consistent with print and get better insurance on fewer passes. Tips: Use a gradual, thorough mix with a smooth spatula, and scrape down the ink walls of your bucket so each combination is uniform. Test for each printability and therapy through running a pattern thru your dryer, then flex the ink deposit and wash test the blouse.

9.How to Achieve Maximum Opacity and Coverage on Shirts

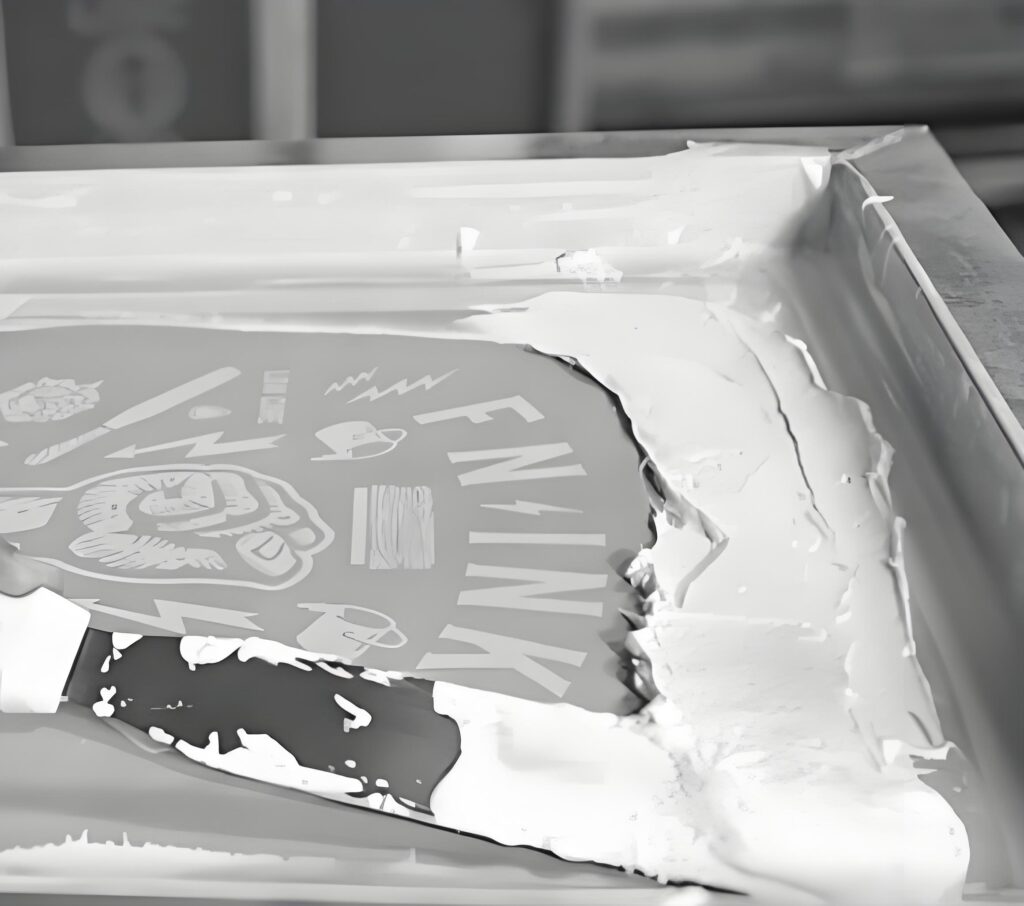

For sharp, vibrant prints, opacity is the whole lot. Choose white plastisol ink with a “excessive opacity” rating for fine consequences, specifically on black shirts. Opaque ink covers the underlying blouse colour absolutely, permitting most effective the actual white to expose via. A thicker ink deposit—performed with the proper squeegee approach and mesh count—creates better insurance but be cautious not to overdo it, which results in stiff, less bendy prints.

Flash curing among layers allow you to build opacity without immoderate buildup, main to smoother, flexible prints that won’t crack without difficulty. Coat your monitors well and use the right emulsion thickness; thin coatings may additionally result in poor coverage, whilst overly thick coatings trap an excessive amount of ink and make cleanup harder. Always take a look at your finished print for brightness, smoothness, and flexible hand before finalizing your process.

10.Top Troubleshooting Tips: Cracks, Bleeding, Scorch, and Wash Durability

Even premium white plastisol ink can fail if dealt with incorrectly. Common problems encompass:

Cracking, which occurs if the ink is over-cured or implemented too thick.

Bleeding or dye migration, a end result of excessive cure temperatures or the usage of the incorrect ink on poly fabrics.

Scorch marks on sensitive polyester or fleece, because of immoderate time or temperature inside the dryer.

Poor wash sturdiness, which is often as a result of below-cured ink or incompatible blending of components.

Quick fixes: Adjust your dryer temperature (decrease or improve as wanted), switch to a low remedy or low bleed ink for poly blends, and usually run a right wash check before delivery jobs to clients. Keep your technique constant—from ink mixing and printer setup to display screen coating and final cure—to guarantee each shirt meets your premium white standard, each time.