Flock printing is a charming mixture of artwork and science, drawing on strategies that elevate wellknown prints to a textured, velvet-like beauty. This blog publish famous the secrets of flock printing and its superior use of plastisol inks and adhesives. Whether you are an industry professional or a curious hobbyist, know-how these methods will enhance your printing ability and creativity. Keep analyzing to study suggestions, enterprise quality practices, and insider knowledge which can make your prints now not only visually lovely but additionally lengthy-lasting and durable.

Article Outline

- What is Flocking Plastisol Ink?

- The position of plastisol gel ink in suede printing

- How does suede adhesive work?

- Which Screen Printing Ink Should You Choose?

- The Importance of Equipment in Flock Printing

- How to use 3820 fluff glue for top-rated results

- Can PVC unfastened printing be performed using fluff technology?

- What Are the Best Practices for Flock Application?

- How to Choose the Right Screen Printing Ink for Your Fabric?

- How Do You Apply Flock Adhesive for Optimal Results?

1.What is Flocking Plastisol Ink?

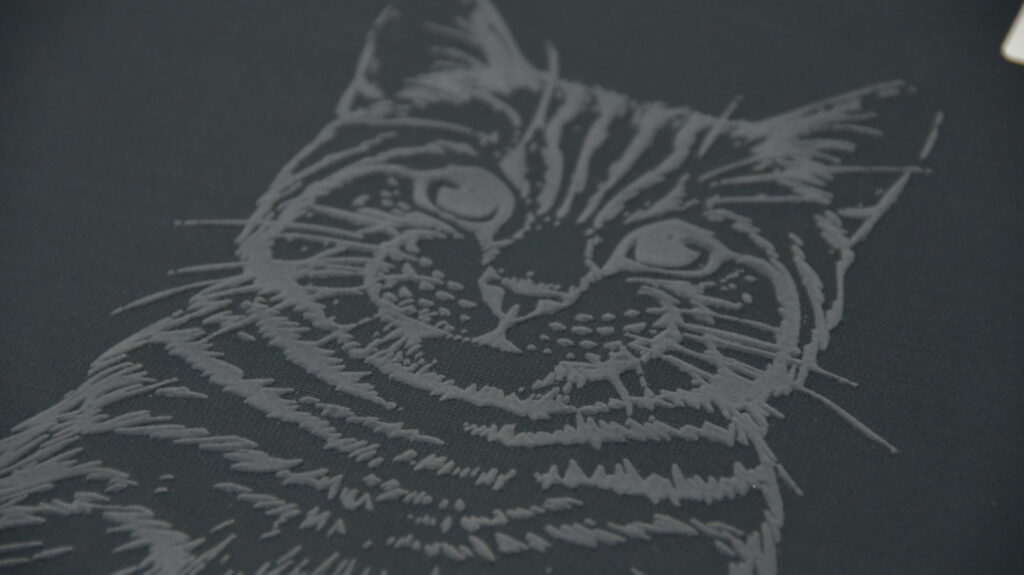

Flock printing is a decorative technique that utilizes short fibers—referred to as “flock”—to create seamless, velvet-like textures on various surfaces, primarily fabrics. The process begins by applying a layer of adhesive, generally a flock adhesive, where the design is imprinted. The fibers are then added to the wet adhesive and adhere to it upon drying, creating a tactile and visually appealing finish.

Flock printing has grown in popularity for its ability to create high-density, durable, and flexible designs that enhance the surface of any material. Its versatility allows for the creation of logos, customized apparel, and even intricate graphic prints. This method is especially appealing for those looking to offer sustainable and smooth-textured surfaces, perfect for both indoor and outdoor applications.

2. The position of plastisol gel ink in suede printing

Plastic sol-gel ink is a key cloth in display printing, recognised for its exquisite insurance and vibrant colorings. These inks are tremendously appropriate for developing complex graphic designs and are a reliable solution inside the industry as they do no longer dry on the display screen, thereby extending manufacturing time.

The use of plastic sol-gel ink in velvet printing can gain vivid and smooth effects by means of dynamically mixing color layers. Plastic sol-gel ink stays gentle and sturdy after curing, which is a necessary function for suede printing. Curing requires heat to permanently soften the ink, which can be completed thru flash dryers or conveyor belt dryers to make certain most sturdiness below regular use.

3.How does suede adhesive work?

Velvet adhesive is a key element of fluff printing, serving as a bonding agent between fibers and fabrics. Adhesive ought to be implemented in a managed way as it determines the durability and texture of the very last product. High high-quality fluff adhesives, together with the extensively encouraged 3820 fluff adhesive, can ensure extremely good bonding overall performance.

The manner of making use of adhesive entails using rubber rollers to evenly cover the chosen display screen vicinity with the adhesive. Subsequently, while the floor of the adhesive is still wet, observe the fluff fibers onto it. As the fibers dry, they’ll be embedded inside the adhesive, forming a robust and sturdy plush printing impact.

4. Which display printing ink ought to be chosen?

Choosing the precise display printing ink can have an effect on the very last impact and durability of the broadcast product. The compatibility among ink, glue, and fibers is essential whilst acting Flocking Plastisol Ink. Choosing screen printing ink especially designed for flocking printing guarantees an excellent aggregate of ink and fibers, ensuing in splendid printing outcomes.

International paint organizations offer a number of customizable inks designed mainly for suede printing. Its special components ink can meet precise safety desires and is appropriate for numerous fabric and fiber kinds. When used efficaciously, those inks provide a gentle sense and consistent shade presentation, making them the industry’s favored choice.

5.The importance of system in velvet printing

Appropriate gadget is vital for the flocking printing method. Investing in fantastic printing machines can enhance performance and decrease waste and errors. Screen printing machines vary in complexity, starting from easy manual presses to complex automation structures, suitable for distinct production scales.

In addition, auxiliary device inclusive of warm presses and dryers play a critical function within the curing system of plastic ink and adhesives. Uniform and regular heat software guarantees that each layer of ink and adhesive is absolutely cured, thereby accomplishing maximum sturdiness.

6. How to use 3820 fluff glue for top-rated results

3820 fluff glue is renowned for its strong adhesive residences and is the desired preference for display printing experts. To gain most excellent effects, it is essential to prepare the adhesive efficiently and strictly follow the producer’s commands, which normally consist of mixing the adhesive with the catalyst inside the distinct proportions.

To achieve the nice bonding effect, make certain that the adhesive is frivolously applied to the favored surface. Smooth coating with uniform stress can save you the formation of bubbles, thereby fending off problems within the formation of long-lasting adhesion among fibers and fabric. Before exposing printed materials to heat or washing, ensure that the adhesive has sufficient drying time.

7.Can PVC unfastened printing be performed using fluff technology?

The challenge for environmental protection has pushed the call for for sustainable printing answers. Flocking printing affords a feasible solution for PVC free display printing ink and materials. By using PVC loose ink and Flocking Plastisol Ink, environmentally pleasant merchandise can be produced with out sacrificing great.

The PVC free solution eliminates the environmental dangers resulting from traditional plastic inks whilst keeping elasticity and super results. More and greater manufacturers and providers are providing PVC unfastened options to ensure that all enterprise demands are sustainably met.

8.What Are the Best Practices for Flock Application?

For most excellent flock application, make certain the adhesive is applied calmly and permit it to dry to a cheesy kingdom earlier than including the flock fibers. This may be carried out the usage of a flash therapy or leaving it to air dry . The fibers ought to then be implemented the use of managed pressure to ensure they stand upright and cling properly to the adhesive.

9.How to Choose the Right Screen Printing Ink for Your Fabric?

Screen printing ink choices vary depending on the fabric type. For materials like cotton, water-based totally inks are usually suitable, even as synthetics like polyester may require specific inks to make certain the colour units and remains colourful despite great wear and washing

10.How Do You Apply Flock Adhesive for Optimal Results?

Proper utility performs a pivotal position inside the effectiveness of flock adhesives. The adhesive must be carried out frivolously and at the correct ratio to make sure complete fiber coverage. Ensuring the adhesive layer isn’t always too thick or too thin is key; a great stability will sell right adhesion without compromising the print’s aesthetics.