Key Takeaways: Metallic Gold Ink Screen Printing at a Glance

- Metallic gold ink offers stunning shimmer and top rate shine, transforming everyday prints into showstoppers.

- Plastisol ink is the enterprise preferred for metallics, handing over excessive opacity, creamy texture, and extraordinary wash sturdiness.

- Thoroughly stir metallic gold ink before every use to maintain a fair shimmer effect.

- Choose the proper screen and mesh count number—typically a hundred and ten-156—for best metallic particle switch and print vibrancy.

- Always use the right therapy temperature (often round 320°F/one hundred sixty°C) and live time to obtain whole fusion for wash sturdiness.

- Low-remedy, low bleed, and non-phthalate metallic inks are fine for warmth-touchy or artificial garments.

- For darkish material, use a base white underlay to maximise opacity and gold shimmer.

- Wash metallic prints internal-out, in cold water, and avoid excessive heat drying to hold their shine.

- Review protection records sheets for components and proper dealing with instructions for each distinctiveness metal ink.

- Troubleshoot not unusual problems like dye migration or ink bleed with the aid of trying out your substances, adjusting remedy temp, and refining print approach.

Explore your subsequent assignment with renewed confidence and experience the unequalled vibrancy and fashion that only steel gold ink can deliver!

Mastering Metallic Gold Ink in Screen Print: Your Complete Guide to Stunning Shimmer and Reliable Results

Do you need to make your prints stand out with rich, shimmering metal gold? Are you curious about how to get that perfect metallic finish the usage of display printing ink, specifically with plastisol ink or different strong point inks? This blog post will show you the whole lot you need to recognize—from the basics of steel gold ink, to best practices for display, print, and cure. Whether you’re a seasoned display screen printer or simply diving into area of expertise ink like steel gold plastisol, this manual is full of recommendations to raise your prints with maximum shine and vibrancy. In the give up, you’ll have actionable insights you can use right away on your next print run. Read on in case you’re ready to learn how to screen print with metal ink and acquire professional, head-turning effects!

Article Outline

- What Makes Metallic Gold Ink So Special in Screen Printing?

- Understanding the Types of Gold Screen Printing Ink: Plastisol, Water-Based, and More

- How Does Metallic Gold Ink Work? The Science of Shine

- Choosing the Right Screen, Mesh, and Stencil for Metallic Gold Prints

- Pro Tips: How to Print with Metallic Inks for Maximum Shimmer

- Perfecting Your Cure: Temperature, Dwell, and Complete Fusion

- Curing Plastisol Ink: Do’s, Don’ts, and Low-Cure Options

- Achieving Opaque and Vibrant Results on Dark Fabrics

- Wash Durability and Care: Keeping Metallic Gold Prints Looking New

- Safety Data, Additives, and Specialty Concerns: What Every Printer Should Know

1. What Makes Metallic Gold Ink So Special in Screen Printing?

Metallic gold ink immediately grabs attention, adding a premium shimmer and sparkle to any display print task. The addition of steel debris—tiny flakes of metals or synthetics—creates a shine that normal ink truely can’t fit. Whether you’re going for ambitious, reflective chrome results or a subtle gold shimmer, the use of a strong point ink like metal gold plastisol opens up a international of fascinating layout opportunities.

Screen printers love to apply metal gold ink as it elevates the look of published garments, posters, or even distinctiveness fabrics. It’s relatively flexible, running properly on cotton, blends, or even polyester while paired with the right base and proper curing technique. Not to say, steel inks frequently have fantastically excessive opacity, making them perfect for printing on each mild and darkish clothes without sacrificing vibrancy.

Beyond just style, the right steel ink can deliver professional-degree print durability and wash resistance, specifically while you choose excessive excellent plastisol display printing ink and dial in your cure temperature and time just right. This is why mastering to master metal gold ink is a must for any critical screen printer inquisitive about area of expertise and premium seems.

2.Understanding the Types of Gold Screen Printing Ink: Plastisol, Water-Based, and More

When it involves printing metal gold, your ink desire subjects—lots. The market gives several options: plastisol ink, water-primarily based ink, acrylic blends, and other forte ink formulations. Each has its region in a screen printer’s toolkit.

Plastisol ink is the gold standard for metallic outcomes, preferred for its creamy, excessive-opacity base that suspends steel particles superbly. It won’t air dry at the display screen, letting you figure at your very own tempo, and when well cured, achieves strong wash durability. Metallic gold plastisol ink is in particular famous as it offers complete fusion with the cloth’s fiber, which means each brilliance and longevity in one print.

Water-based ink is much less not unusual for steel however can paintings if you’re focused on eco-aware markets or searching out a softer print finish—just don’t assume the same level of metal shimmer or opacity as with plastisol. Acrylic-based totally area of expertise inks, in the meantime, provide interesting blends for precise effects however frequently require unique additives to keep metal particles in suspension and to cure successfully.

Choosing water-based or different strong point steel gold ink entails trade-offs between vibrancy, ease of cure, and substrate compatibility. But for maximum packages in which shimmer, shine, and durability are priorities, plastisol metallic inks are the clear winner.

3.How Does Metallic Gold Ink Work? The Science of Shine

The extraordinary effect of steel gold screen printing ink comes down to technological know-how. Inside every bucket of metallic ink, you’ll discover a suspension of steel particles—aluminum, bronze, or synthetic flakes—swirling in a automobile that’s either plastisol, water-primarily based, or acrylic. These metallic debris replicate light at exceptional angles, producing that conventional gold shimmer and top class sparkle that turns ordinary prints into showstoppers.

For most shine, the particles have to be frivolously dispersed in the course of the ink, this means that a mild stir earlier than every use—a step many printers pass. The right blend of steel flakes is vital to avoid clumping and ensure a clean print. Some forte metal gold ink formulas might even comprise chrome or different metallics for a unique shimmery impact.

The length of those steel particles determines the final appearance: smaller flakes produce a smoother, extra “chrome” end; larger flakes ramp up the glint but can make the print feel difficult to the touch. Understanding how to formulate, blend, and manage your steel gold ink is fundamental to unlocking its full capability—both in phrases of visible impact and practical sturdiness.

4. Choosing the Right Screen, Mesh, and Stencil for Metallic Gold Prints

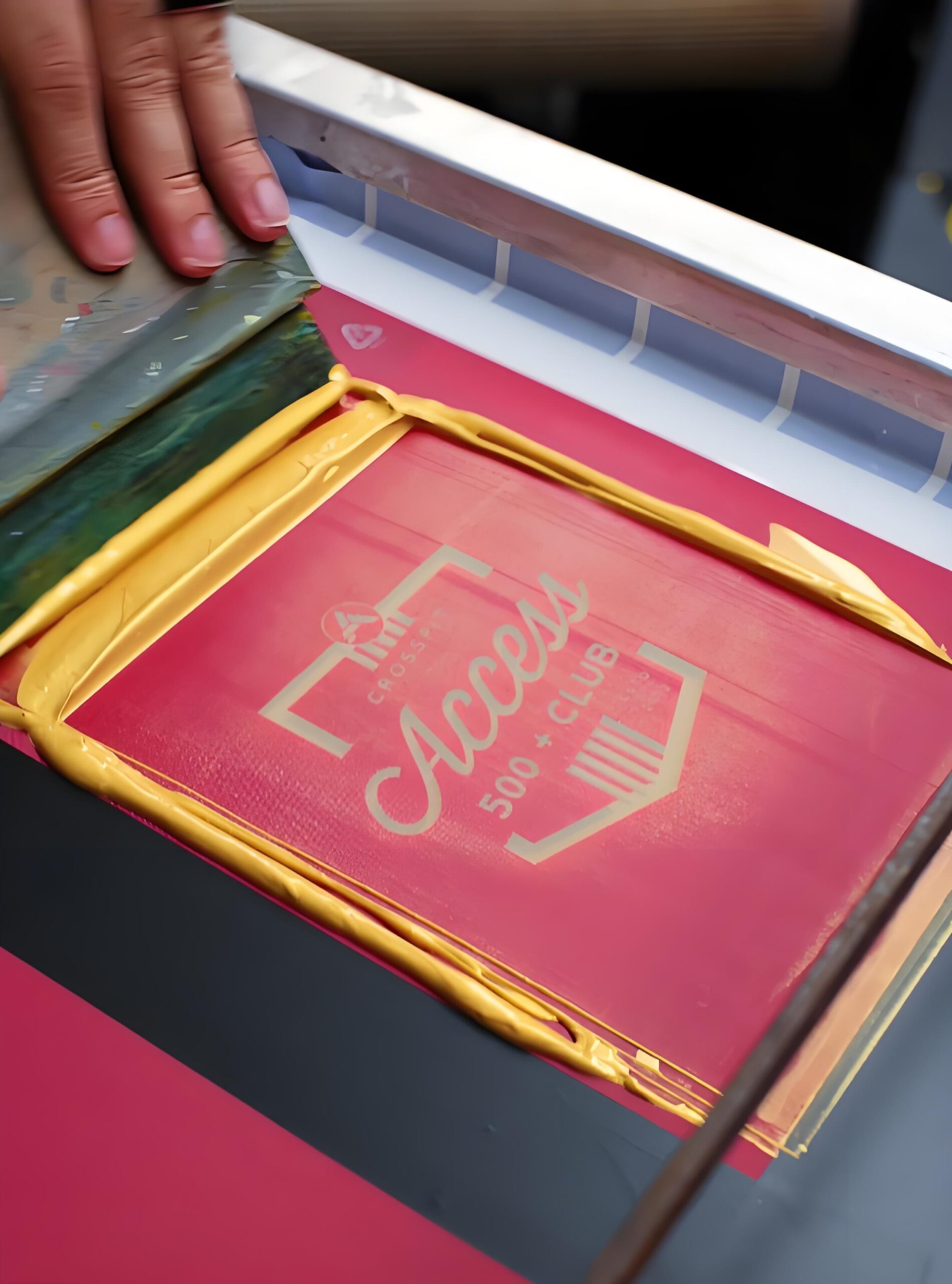

Your choice of display and mesh can make or ruin your metallic gold print. Since metal debris are generally larger than wellknown pigments, the use of the right mesh remember is important—in maximum cases, a mesh inside the 110-156 variety works high-quality. A better mesh be counted may also restriction metal debris and diminish opacity, even as a too-low mesh can result in extra ink deposit and detail loss.

Don’t forget approximately your stencil and emulsion. Opt for a excessive-opacity, durable emulsion that could rise up to the abrasive nature of metallic inks. The stencil also determines how comfortably the metallic gold ink actions through the mesh, affecting your final print’s shimmer and vibrancy.

Proper tensioning of the display screen guarantees crisp prints and limits the hazard of blurry edges or ink bleed. For most impact, display screen printers frequently select a barely coarser mesh, which allows huge metal flakes to bypass via, developing that colourful gold shimmer impact at the cloth.

5. Pro Tips: How to Print with Metallic Inks for Maximum Shimmer

To unharness the maximum sparkle out of your steel gold ink, awareness on technique. First, stir your ink thoroughly proper before printing to droop the steel particles evenly—with out this, the shimmer impact will appear blotchy or dull. Next, regulate your off-contact distance and squeegee pressure: metal inks usually want a slightly better off-touch and more impregnable pressure to transfer heavier debris cleanly through the screen.

Printing metal gold at once onto a cloth will deliver a beautiful shimmer, but for added punch on darkish garments, recollect a base white layer (either underbase or highlight). This base will enhance vibrancy and assist the gold pop, making the steel debris seem extra opaque and reflective. Be sure to allow the bottom color flash dry properly before printing gold on top.

Finally, proper drying and curing are important. Missteps here can break each shine and durability, so always pay careful attention to temperature and dwell time to your dryer or conveyor.

6.Perfecting Your Cure: Temperature, Dwell, and Complete Fusion

Curing is vital for plastisol ink, and doubly so for steel gold prints. Achieving complete fusion of ink and fiber demands careful temperature manipulate. Most plastisol steel gold inks remedy at round 320°F (one hundred sixty°C), even though a few low-remedy and uniqueness ink formulations can set at decrease temperatures, helping save you dye migration and garment sizzling.

Pay near interest to reside time: this is the length of time your print spends in the dryer at the right temperature. Too little stay results in incorrect remedy, risking poor wash sturdiness and muted shine. Too a whole lot warmness, on the other hand, can overbake the ink or make the metal particles stupid in place of shiny.

A conveyor dryer is good for even, steady warmness. If you’re working with area of expertise or non-phthalate metal inks, always check the manufacturer’s protection statistics—as an instance, a few inks may also require specific temperature profiles or extra additives to reap a real metal shimmer and right fusion to the cloth.

7. Curing Plastisol Ink: Do’s, Don’ts, and Low-Cure Options

Nailing the treatment on plastisol ink is a non-negotiable ability for every screen printer. For preferred metal gold ink, always pretest your dryer’s temperature profile with a temp gun or test strip. Run pattern prints via your infrared or conveyor dryer, then flex the print to test for complete fusion (no cracking or flaking).

Low-remedy plastisol inks are a sport-changer for printing on heat-touchy fabrics like polyester or uniqueness blends, as they lessen the chance of dye migration, scorching, or shrinkage. Some gold plastisol ink formulas are specially engineered as low bleed and coffee-treatment, which is best for difficult, excessive-performance garments.

Steer clean of air dry methods—plastisol inks ought to reach their cautioned cure temperature for whole fusion and maximum sturdiness. And bear in mind, double-check the protection statistics and technical sheets on your specific steel gold ink before use, as remedy necessities can differ based on whether the formulation is popular, non-phthalate, or uniqueness.

8. Achieving Opaque and Vibrant Results on Dark Fabrics

Want your gold shimmer to pop on black tees? Start with opacity. Some metal inks are excessive opacity with the aid of default, but for last vibrancy and shimmer, use a base white layer. Strike the proper stability: a skinny, flash-cured base white provides reflectivity without making the very last print experience thick and heavy.

When printing on darkish garments, the usage of a forte metal ink can yield a extra chromatic, reflect-like finish, mainly in case your display screen, mesh, and curing steps are optimized for metallics. Adjust your print method with a slightly heavier ink deposit—it facilitates the metal gold stand proud above the fabric fibers, improving seen shimmer and vibrancy.

Also, consider the material’s fiber mixture. Gold ink behaves in another way on one hundred% cotton as compared to polyester or combined clothes. On synthetics, low bleed or dye-blockading metal gold plastisol ink is your satisfactory pal to prevent unpleasant dye migration from the garment into the ink layer.

9. Wash Durability and Care: Keeping Metallic Gold Prints Looking New

No one desires a stunning steel print that fades or peels after some washes. The secret to scrub sturdiness is a right remedy, which guarantees the ink achieves whole fusion with the garment’s fiber. For metal gold, ensuring that the ink layer isn’t too thick (to keep away from cracking) and that the cure is even throughout the dryer’s width is critical.

Educate your customers: for exceptional results, wash published garments inner out, in cold water, and keep away from high warmness tumble drying. This preserves the steel particles and continues the shimmer intact longer.

Using top rate steel gold plastisol ink and following label safety statistics ensures prints now not most effective look exceptional proper out of the dryer but preserve their shine and integrity through dozens of wash and put on cycles.

10.Safety Data, Additives, and Specialty Concerns: What Every Printer Should Know

Before you dive into your next metallic print run, review the safety facts for every metal gold ink or strong point ink you’ll use. Some plastisol and uniqueness steel inks might also contain additives, metallic particles, or chemical substances that require gloves, proper air flow, or maybe avoidance of direct sunlight throughout storage.

Want even greater shine or sparkle? Some specialty steel inks permit you to upload glitter or “shimmer impact” particles, however usually take a look at that your selected additive is well matched with the ink to prevent clogging your display or altering cure temperature.

Finally, constantly keep metallic gold plastisol ink at room temperature and hold it tightly sealed to keep away from drying or contamination by way of dirt or fiber debris between print runs.