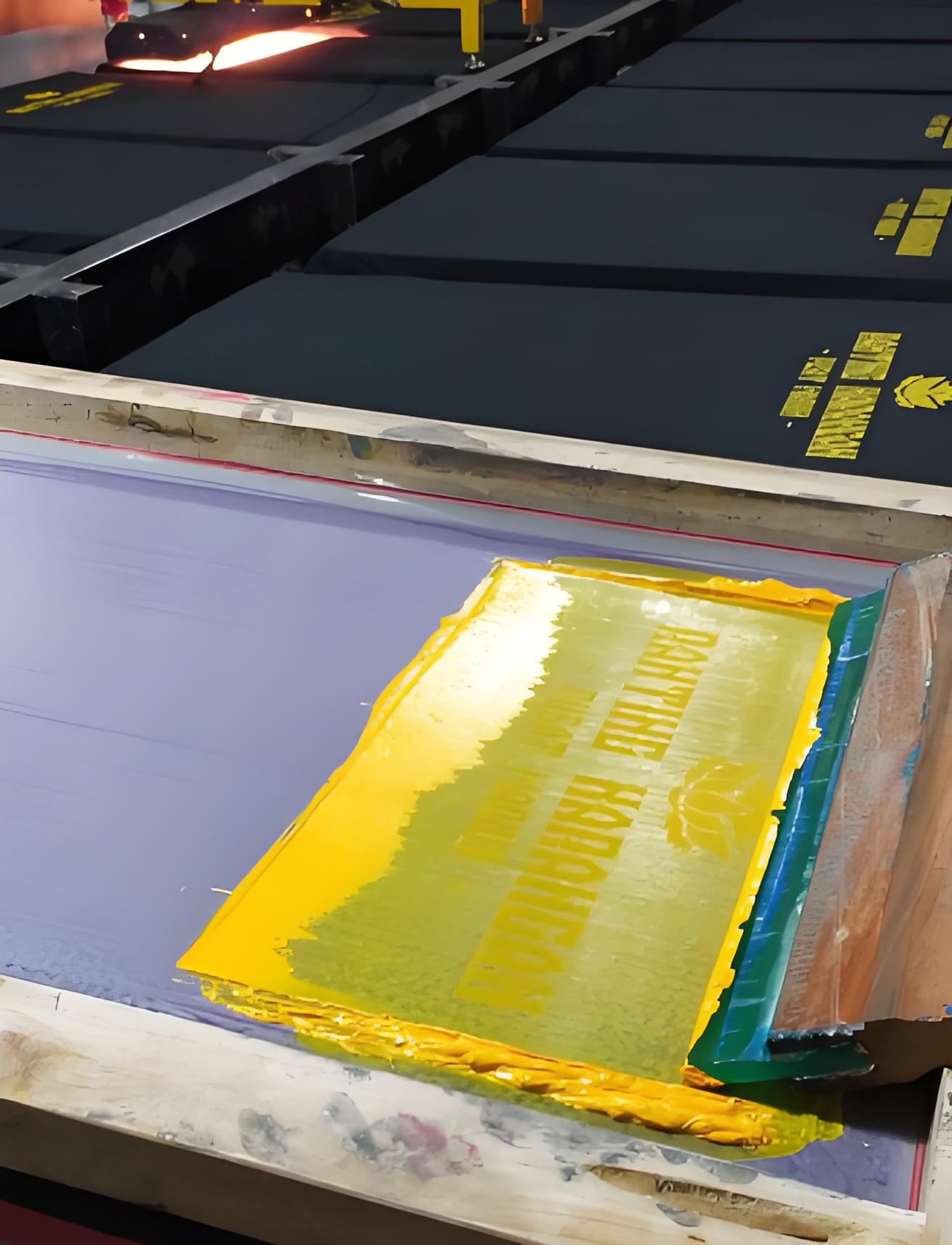

In the world of screen printing, fountain screen printing is emerging as a creative and artistic technique that bridges tradition with innovation. By blending multiple inks directly on a single screen, this method creates seamless, multi-colored gradients, eliminating the need for multiple screens and enhancing visual appeal. It is a core printing technique that SHALITEINK passionately promotes, combining artistic freedom with professional execution.

1. The Artistic Value and Practical Benefits of Fountain Printing

Unlike traditional screen printing, which requires one screen per color, fountain printing utilizes a single screen to blend multiple inks, creating smooth, flowing color transitions. This method is efficient and produces unique, visually striking designs that are highly valued by designers and independent brands.

The three major advantages emphasized by SHALITEINK:

- One screen, multiple colors, simplified process

- Each print is unique, adding value

- High visual impact, enhancing brand recognition

Every print is an experiment in color and artistry, making fountain printing a powerful tool for distinctive, high-impact designs.

2. Material Preparation and Professional Advice

Recommended Inks:

SHALITEINK strongly recommends using high-viscosity plastisol inks, which offer better control and help maintain distinct color boundaries, preventing excessive blending.

Tip: Choose contrasting or complementary color combinations. Avoid colors that may merge into a dull or muddy tone.

Garment and Fabric Selection:

Select garments in colors that contrast with the inks used. Avoid using fabric colors too close to the ink shades, such as blue ink on blue shirts, as it will obscure the design.

Ink Application Method:

- Apply ink in stripes or dollops at the top of the screen

- Maintain a small gap between colors, avoiding premature blending

- Use SHALITEINK’s high-quality spatula tools for even pressure and superior results

3. Test Prints and Color Control

Before full-scale production, SHALITEINK recommends running 4–5 test prints to observe how the gradient evolves. Avoid overloading the screen with ink, as too much ink may cause the colors to mix too quickly, flattening the gradient effect.

4. Ink Maintenance and Creative Updates

During the printing process, as the ink begins to blend, you may notice that the gradient becomes dull or loses its definition. At this point, it’s essential to clean the screen and reapply fresh ink. SHALITEINK encourages you to refresh the design by either sticking with the original color sequence or introducing new colors, adding creative variety to the print run.

5. Squeegee Control: Precision is Key to the Gradient

Fountain printing requires squeegee consistency more than just angle adjustments. Any shift in the squeegee’s left or right movement will disrupt the color blending, affecting the gradient.

SHALITEINK recommends using the pull stroke technique, which provides better control over ink flow and pressure. Ensuring a steady hand throughout the print run is essential to maintaining gradient continuity.

6. Creative Techniques and Variations

Fountain printing offers a vast landscape for creative experimentation. With SHALITEINK’s premium tools, you can expand your design possibilities:

- Wave strokes: for creating fluid, undulating gradient effects

- Circular pulls: to create radial or spiral patterns

- Random dotting + single pass: to produce marbled or cloud-like textures

Every stroke you make can become part of your signature style.

7. Application Scenarios: Printing Your Brand and Identity

SHALITEINK has seen fountain printing applied successfully in a variety of industries, including:

- Limited edition collections: Each piece becomes unique, enhancing its collectible value

- Event merchandise: Perfect for festivals, exhibitions, or promotional campaigns

- Streetwear and fashion: Creates eye-catching designs that establish a distinctive brand identity

- Art prints: Extends the technique to various media, including fabric and paper

Fountain printing also works well with hybrid techniques, such as metallic inks, puff ink, and embroidery, creating a multi-dimensional effect.

8. Common Issues and SHALITEINK Solutions

| Issue | Cause | SHALITEINK Solution |

|---|---|---|

| Dull / muddy colors | Incorrect ink combination or overmixing | Use vibrant, high-contrast inks; reduce initial ink amount |

| Inconsistent gradients | Squeegee movement inconsistent | Mark hand positions and maintain steady motion |

| Excessive ink blending | Overloaded screen or excessive pulls | Limit ink amounts, refresh regularly |

| Polluted transitions | Incompatible inks or unclean tools | Use compatible inks (we recommend plastisol), clean tools frequently |

9. SHALITEINK’s Professional Tips

- Document your process: Take photos of your ink layout and squeegee movement for easier replication of successful results

- Start small with color combinations: Begin with 2–3 colors before progressing to more complex blends

- Experiment with materials: Try printing on cotton, canvas, denim, or even paper for different textures

- Keep tools clean: SHALITEINK offers cleaning solutions and screen maintenance kits to ensure your tools last longer and perform better

Conclusion: Unleash Creativity and Control Color Flow with SHALITEINK

Fountain screen printing is more than just a technique; it’s a method that blends artistry with process. With SHALITEINK’s expert solutions, you can seamlessly go from concept to print, creating high-quality, visually stunning works with minimal effort.

SHALITEINK encourages every creator to step outside the box and explore the world of fountain printing, where color flows and the possibilities are endless.