Are you looking to print on shirts? Do you want the colors to pop? Then, plastisol ink might be for you. This ink is special.

It helps make bright and strong pictures on clothes. Let’s learn all about plastisol ink.

What is Plastisol Ink?

Plastisol ink is used for screen printing. Screen printing is a way to put pictures on things. This ink is thick. It sits on top of the cloth. It does not soak in. This makes the colors very bright.

Think of it like paint on a wall. The paint sits on the wall. It covers the color of the wall. Plastisol ink does the same thing on cloth.

Why Use Plastisol Ink?

There are many good things about using plastisol ink:

- Lasts Long: The pictures stay bright for a long time.

- Works on Many Things: You can use it on shirts, bags, and more.

- Bright Colors: The colors are very strong and easy to see.

- Easy to Use: It is easy to work with.

Different Kinds of Plastisol Ink

There are many kinds of plastisol ink. Each kind does something special.

Here are some types of special plastisol ink:

- Reflective Ink: This ink shines when light hits it. It is good for safety clothes. Explore our Reflective Plastisol Ink.

- Puff Ink: This ink pops up when you heat it. It makes the picture feel bumpy.

- Glow in the Dark Ink: This ink glows when it is dark.

1. Introduction to Plastisol Inks in Screen Printing

Plastisol inks are very popular in screen printing.

- They work well.

- They are easy to use.

- They last.

These inks are made of tiny plastic pieces in a liquid. When you heat the ink, the plastic melts and sticks to the cloth.

What makes plastisol inks the go-to choice for screen printing?

Plastisol inks are a top pick because:

- Easy to Use: It is simple to print with .

- Bright Colors: The colors look good.

- Lasts Long: It stays on the shirt for a long time.

- Works on Many Fabrics: You can use it on cotton, polyester, and more.

Overview of specialty plastisol inks (e.g., reflective, metallic, puff) and their applications

Specialty plastisol inks do even more.

- Reflective: Shines when light hits it . It is good for night clothes.

- Metallic: Looks like metal . It adds a shiny touch to shirts.

- Puff: It puffs up when you heat it . It makes a raised design.

- Chameleon Ink: Changes color based on heat or light, adding a dynamic effect .

- Foil Plastisol Ink: Allows foil to adhere to the print, creating a metallic or shiny look.

These inks let you make cool and different designs.

2. Key Benefits of Plastisol Inks

Plastisol inks have many good things about them.

Durability: High resistance to fading, cracking, and washing

Plastisol inks are tough.

- They do not fade in the sun.

- They do not crack when you stretch them.

- They do not wash off in the washing machine.

This means your designs will look good for a long time.

Versatility: Compatibility with cotton, polyester, blends, and promotional items

You can use plastisol inks on many different things.

- Cotton shirts

- Polyester bags

- Mixed fabrics

- Ads

This ink sticks well to many things.

Vivid Results: High opacity and vibrant color retention for bold designs

Plastisol inks make bright colors.

- The colors are strong.

- They do not fade.

- They cover the fabric well.

This makes your designs stand out.

3. Top Specialty Plastisol Ink Types

There are many kinds of special plastisol inks. Let’s learn about some of them.

Reflective Inks: Light-reflecting microspheres for safety apparel and visibility

Reflective inks have tiny balls that shine when light hits them.

- They are good for safety clothes.

- They help people see you at night.

- Workers and athletes often use this ink.

Explore our Reflective Plastisol Ink.

Eco-Friendly Options: Phthalate-free and reduced-plasticizer formulas for sustainability

Eco-friendly inks are better for the Earth.

- They do not have bad chemicals.

- They help the planet.

- More and more people want these inks.

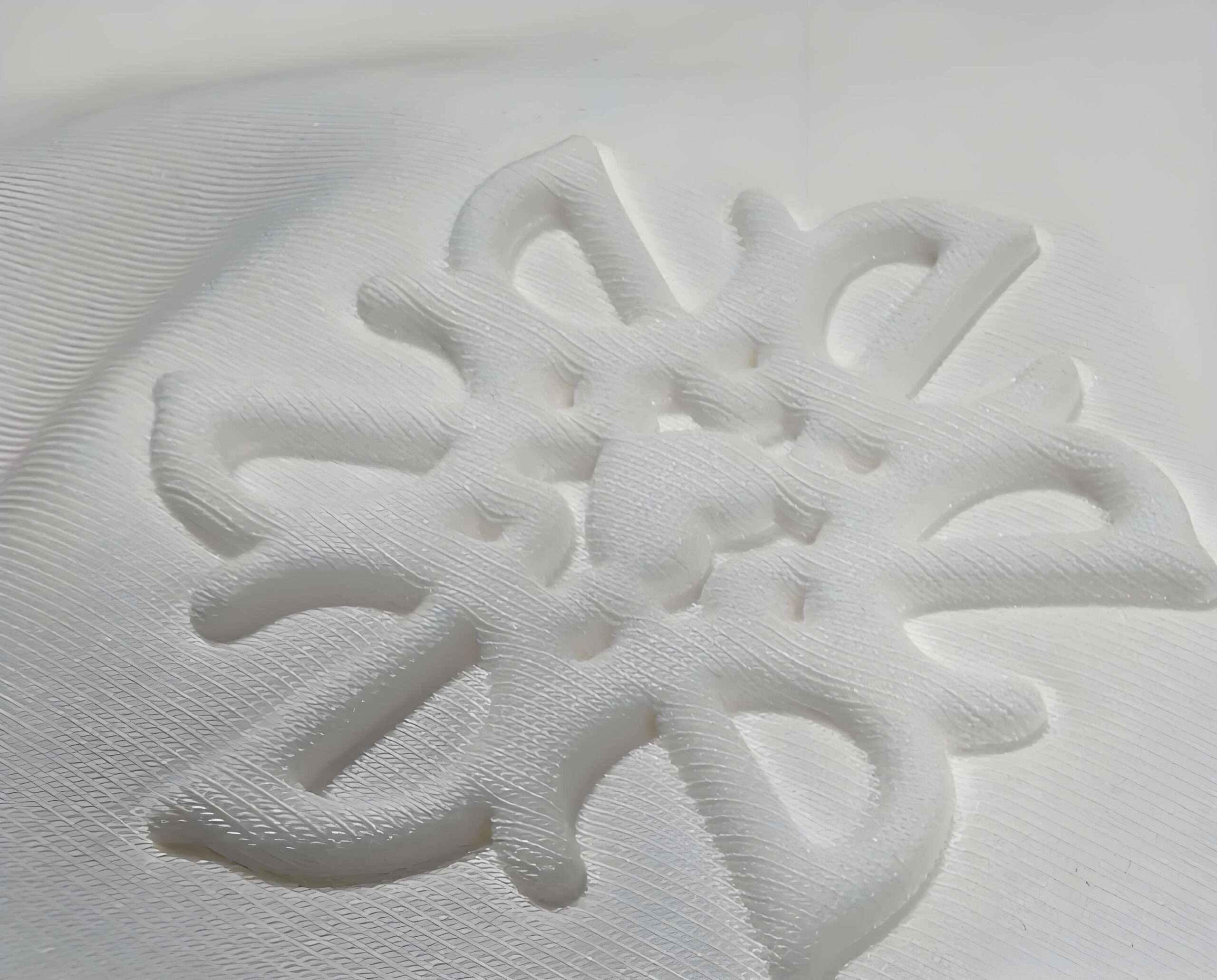

Textured Effects: Puff, shimmer, and high-density inks for unique finishes

These inks make different textures on the cloth.

- Puff ink pops up.

- Shimmer ink sparkles.

- High-density ink is thick.

These inks make your designs special. For a cool look, try Puff Plastisol Ink.

- Chameleon Plastisol Ink: Changes color depending on the angle of light. A truly eye catching option for specialty garments. You can find Chameleon Screen Printing Plastisol Ink online for a great price!

- Foil Plastisol Ink: This ink acts as a glue so that you can add Foil to your garment.

- Glow In The Dark Pink Plastisol Ink: This specialty ink is great for night time visibility. You can purchase Glow In The Dark Pink Plastisol Ink here.

4. How to Choose the Right Plastisol Supplier

Picking the right supplier is important. You want good ink and good service.

Quality Assurance: Compliance with REACH/OSHA standards and safety protocols

Make sure the supplier follows safety rules.

- The ink should be safe to use.

- It should not have bad chemicals.

- The supplier should care about safety.

Product Range: Availability of specialty inks (e.g., non-blocking, UV-resistant)

The supplier should have many kinds of ink.

- They should have specialty inks.

- They should have inks for different jobs.

- This gives you more choices.

Supplier Reputation: Trusted distributors like Texsource Inc. and Plastisolink.us

Pick a supplier that people trust.

- Read reviews.

- Ask other printers.

- Make sure they have a good name.

5. Application Tips for Optimal Results

To get the best results, you need to use the ink right.

Curing Best Practices: Ideal temperatures and curing times for longevity

Curing means heating the ink to make it stick.

- Use the right temperature.

- Heat it for the right time.

- This makes the ink last longer.

Ink Layering: Techniques for underbases and multi-color designs

Layering means putting one color on top of another.

- Use an underbase for bright colors.

- Line up the colors right.

- This makes the design look good.

Fabric Compatibility: Adjusting ink formulas for stretchable or fine fabrics

Some inks work better on some fabrics.

- Use special ink for stretchy fabric.

- Use thin ink for fine fabric.

- This makes the print look good on any fabric.

6. Troubleshooting Common Issues

Sometimes, things can go wrong. Here’s how to fix them.

Ink Adhesion Problems: Fixing flaking or cracking on synthetic fabrics

If the ink is peeling off, try these:

- Clean the fabric well.

- Use special ink for synthetic fabric.

- Heat the ink for longer.

Curing Challenges: Addressing under- or over-cured prints

If the ink is not curing right, try these:

- Check the temperature.

- Check the time.

- Make sure the heater is working.

Safety Concerns: Reducing odor and ensuring workspace compliance

Safety is very important.

- Work in a well-ventilated place.

- Use ink with low odor.

- Follow all safety rules.

7. Future Trends in Plastisol Inks

Plastisol inks are always changing.

Sustainability: Growth of eco-friendly and water-based alternatives

More people want inks that are good for the Earth.

- Eco-friendly inks are becoming more popular.

- These inks use fewer chemicals.

- They help the planet.

Innovations: Smart inks with thermochromic or glow-in-the-dark properties

New inks can do cool things.

- Some change color with heat.

- Some glow in the dark.

- These inks make printing more fun.

Market Demands: Increasing use in sportswear and industrial printing

Plastisol inks are used in many new ways.

- They are used in sportswear.

- They are used in factories.

- The market for these inks is growing.

| Category | Data/Statistic/Case Study | Context & Source |

|---|---|---|

| Market Growth | Plastisol market to grow from $25.07B (2024) to $26.95B (2025) at 7.5% CAGR | Driven by industrial applications, automotive demand, and medical products. |

| Key Statistics | Screen Printing Inks Market valued at $4.41B (2023), projected 3.1% CAGR to $5.81B (2032) | Textile printing covers 55% of the market, followed by automotive (18%). |

| Industry Demand | Asia-Pacific and North America lead demand due to customized apparel and sportswear growth | Sportswear and fashion industries drive vibrant, durable prints on garments. |

| Sustainability Trends | Eco-friendly plastisol inks adoption rising at 15% CAGR (case study data) | Shift toward phthalate-free, low-VOC formulations aligns with regulations like REACH. |

| Regional Insights | Asia-Pacific dominates 40% market share in plastisol inks for screen printing | Growth fueled by textile manufacturing hubs in China, India, and Vietnam. |

| Case Studies | Reflective ink use increased sales by 40% for safety apparel brands (DIC Graphics data) | Optilux®-style reflective inks for night visibility in sportswear and workwear. |

| Application Breakdown | Automotive plastisol demand grows at 6.8% CAGR (heat-resistant adhesives/coatings) | Used for car decals, interior textiles, and branding. |

8. Conclusion: Partnering with the Right Supplier

Plastisol inks are great for screen printing.

Recap of plastisol ink advantages for screen printing

- They make bright colors.

- They last long.

- They work on many things.

Importance of selecting suppliers that prioritize quality, innovation, and compliance

Pick a supplier that cares about:

- Good ink.

- New ideas.

- Safety.

This will help you make the best prints!

Internal Links:

- Explore a wide range of specialty inks for unique designs and effects.

- Discover the benefits of Puff Plastisol Ink for adding texture and dimension to your prints.

- Enhance visibility and safety with high-quality Reflective Plastisol Ink.