The Ultimate Guide to Glitter Plastisol Ink

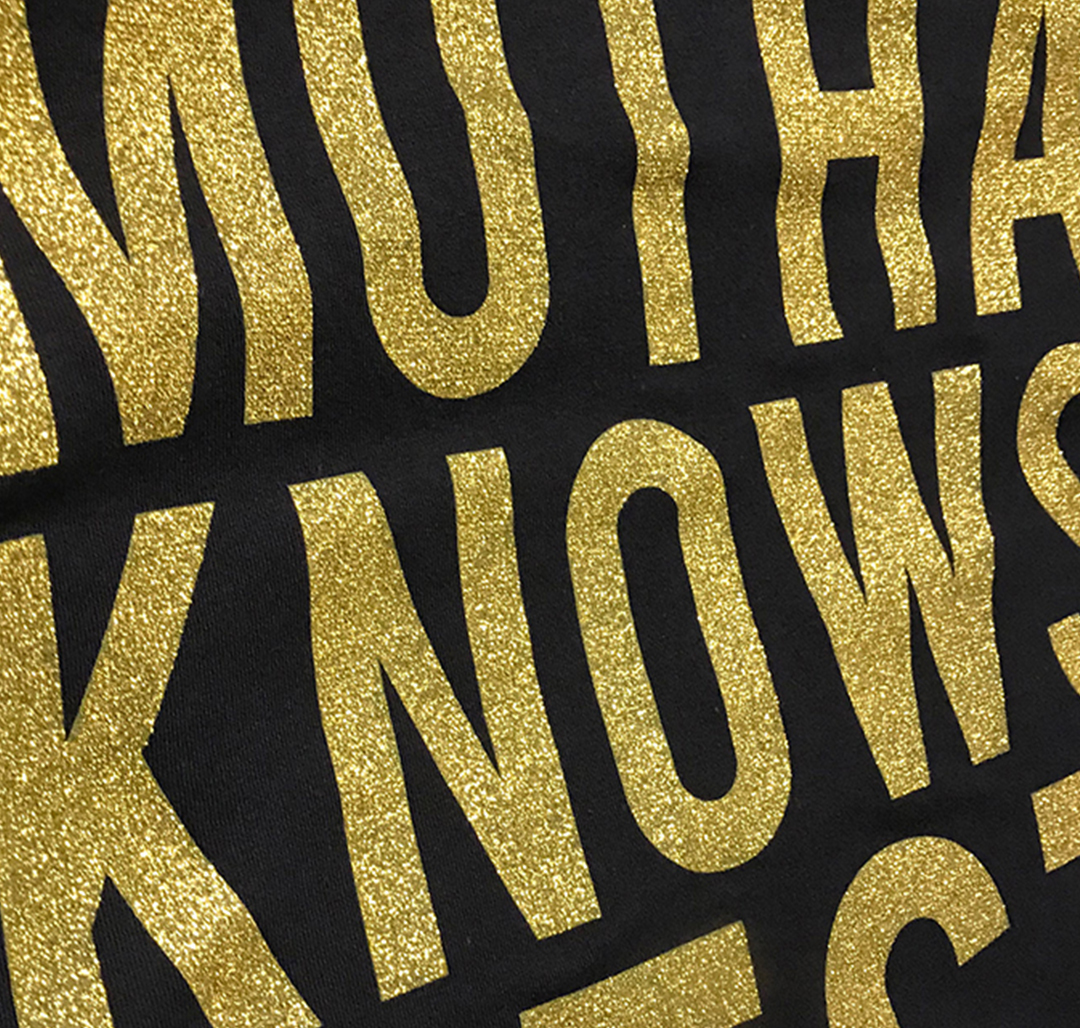

Glitter Plastisol Ink

Glitter Plastisol Ink is a screen printing ink that incorporates fine glitter particles to create a sparkling, eye-catching effect on garments and other textiles. This ink is perfect for adding a touch of shimmer and shine to designs, making it popular in fashion, promotional apparel, and event merchandise.As a global Screen Printing Ink Manufacturer and Factory of superior Screen Printing Ink, Ecoprinting brings an answer focused on productivity, consistency, and environmental duty.

Key Features of Glitter Plastisol Ink:

- Shimmering Finish: Contains glitter particles that produce a sparkling, reflective surface on printed designs.

- High Opacity: Offers excellent coverage, especially on dark fabrics, ensuring the glitter effect stands out.

- Durable and Wash-resistant: Maintains its sparkle and adhesion after multiple washes, making it ideal for long-lasting prints.

- Versatile Particle Sizes: Available in different glitter sizes (fine or coarse) for varied effects, from subtle shimmer to bold sparkle.

- Wide Range of Colors: Comes in various glitter colors, including silver, gold, red, blue, and more, allowing for creative flexibility.

Benefits:

- Enhanced Visual Appeal: The glitter effect adds a fun, glamorous, or festive touch to garments, making designs more attractive and engaging.

- Versatility in Design: Suitable for creating eye-catching logos, lettering, and graphic elements, it’s often used in fashion, sportswear, and children’s apparel.

- Wide Application: Can be applied to various fabrics, including cotton, polyester, and blends, making it versatile for different garment types.

- Customizable Sparkle Intensity: By adjusting the amount of glitter and ink thickness, you can control the level of sparkle from subtle to bold.

Technical Details:

- Curing Temperature: Typically cured at 320°F (160°C) to ensure proper adhesion and durability.

- Surface Drying: The ink tends to dry quickly on the surface, making it easy to handle during the printing process.

- Recommended Mesh: 30 to 61 mesh count is ideal for glitter inks, as it allows the larger glitter particles to pass through.

- Squeegee Recommendations: A medium squeegee pressure is recommended for even distribution of glitter particles without flattening them.

Application and Usage:

- Fabrics: Works best on natural and synthetic fabrics such as cotton, polyester, and cotton blends.

- Printing Techniques: Glitter Plastisol ink is often printed on its own or combined with other inks for mixed effects. It is commonly used as an overlay or accent to enhance designs with sparkle.

- Creative Uses: Frequently used for special events, cheerleading outfits, concert merchandise, and children’s clothing due to its playful and dynamic finish.

Achieving the Best Results:

- Layering and Detail: Glitter ink is generally printed with a thicker deposit to achieve maximum sparkle. Use a coarser mesh to allow glitter particles to pass through easily.

- Durability: For long-lasting results, it’s important to properly cure the ink and wash garments inside out on a gentle cycle to maintain the glitter effect.

Glitter Plastisol Ink provides a dazzling, high-impact finish that enhances any design with shimmer and shine, perfect for making garments stand out in a fun and festive way.

Related products

-

Gold Silkscreen Ink

Sunrise Metallic Screen Printing Plastisol Inks

-

Gold Silkscreen Ink

Sandy Metallic Screen Printing Plastisol Inks

-

Gold Silkscreen Ink

Shimmering Blue Plastisol Inks

-

Specialty Inks

Puff Plastisol Ink