Conclusion

Metallic Gold Screen Printing Ink is a versatile and visually stunning option for artists and screen printers looking to add a touch of luxury to their designs. With the right materials, preparation, and application techniques, you can create durable, high-shine prints that captivate and impress. Whether you’re printing on apparel, accessories, or home décor items, Metallic Gold Screen Printing Ink offers endless creative possibilities.

Mastering the use of Gold Silkscreen Ink and Silkscreen Ink for Fabric requires practice, but once perfected, the results are truly rewarding. With its brilliant metallic finish, this ink can take your screen printing projects to the next level, making them stand out in any setting.

Metallic Gold Screen Printing Ink for Maximum Shine

Screen printing has become one of the most versatile methods for creating bold, striking designs on various fabrics. Among the wide variety of inks available, Metallic Gold Screen Printing Ink stands out for its vibrant sheen, offering a luxurious and eye-catching appeal. This ink brings a shimmering, high-impact finish to any design, making it perfect for projects that need to make a statement. Whether you’re a seasoned screen printer or just getting started, mastering the use of Metallic Gold Screen Printing Ink can enhance your creativity and lead to stunning results. In this article, we’ll explore how to use Metallic Gold Screen Printing Ink to achieve maximum shine while ensuring high-quality, long-lasting prints.

Why Choose Metallic Gold Screen Printing Ink?

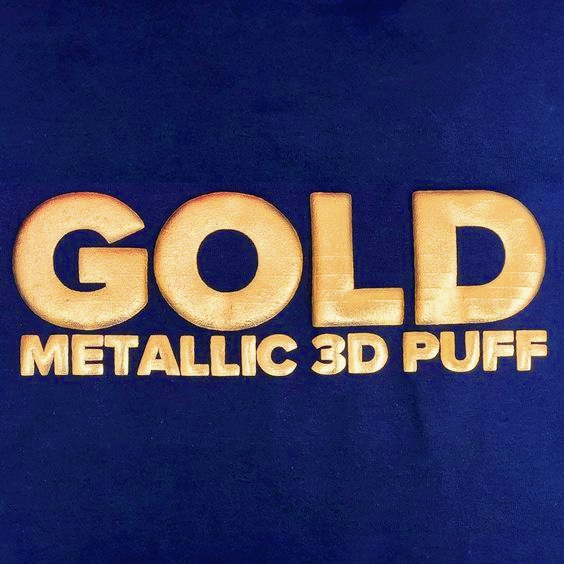

Choosing Metallic Gold Screen Printing Ink offers many benefits for artists and screen printers. Unlike traditional inks, this ink contains reflective metallic particles that produce a brilliant gold finish, adding depth and dimension to your designs. Gold Silkscreen Ink provides a similar effect but is especially well-suited for fabric, making it ideal for custom apparel, promotional items, and home décor projects.

With Metallic Gold Screen Printing Ink, your designs will stand out with a professional-quality look, and its durability ensures that your plastisol print will retain its shine even after multiple washes. This ink is perfect for both bold graphic designs and intricate details, giving your prints a luxurious, high-end feel.

Selecting the Right Materials

Before starting your screen printing project, it’s important to choose the correct materials to ensure the best results with Metallic Gold Screen Printing Ink. First, select a suitable fabric that works well with metallic inks. Silkscreen Ink for Fabric, especially Gold Silkscreen Ink, is compatible with a wide range of fabrics, including cotton, polyester, and fabric blends.

Next, you’ll need a silk screen frame with a mesh count between 110 and 156. A lower mesh count will allow more ink to pass through, which is ideal for thicker metallic inks like Metallic Gold Screen Printing Ink. The quality of your screen printing materials will impact the longevity and quality of your prints, so invest in high-quality mesh screens, squeegees, and other tools for the best outcome.

Preparing the Silk Screen

Proper preparation is essential when working with Metallic Gold Screen Printing Ink. Start by coating your silk screen with an emulsion that is appropriate for plastisol inks, such as screen printing plastisol ink. Make sure the emulsion is applied evenly, as any inconsistencies can affect the final print quality.

Once the emulsion has been applied, allow the screen to dry in a dark, ventilated area. After drying, expose your design onto the screen using a UV light. This process hardens the emulsion in areas where light hits it, while the design remains soft, allowing the ink to pass through.

Creating Your Design

When creating a design for Metallic Gold Screen Printing Ink, consider how the reflective nature of the ink will impact the overall look. Designs with bold, simple shapes work exceptionally well, as they allow the metallic particles to catch the light and create a dramatic effect. Detailed, intricate designs can also work, but keep in mind that metallic inks may require a bit more attention to detail during the printing process.

To ensure high-quality results, create your design using professional graphic design software like Adobe Illustrator or CorelDRAW. Print your final design onto a transparent film, which will serve as the template for exposing the design onto the silk screen.

Applying the Metallic Gold Screen Printing Ink

With your screen prepared and design exposed, it’s time to apply the Metallic Gold Screen Printing Ink. Place your fabric on a flat, smooth surface, ensuring there are no wrinkles. Position the screen on top of the fabric and apply a small amount of the Metallic Gold Screen Printing Ink at the top of the screen.

Use a squeegee to pull the ink evenly across the screen. Applying the right amount of pressure is key here, as too much or too little pressure can result in uneven prints. One of the biggest advantages of Gold Silkscreen Ink and screen printing plastisol ink is their ability to create smooth, vibrant prints with a single pass, so aim for a steady and controlled application.

Curing the Print

Curing the ink is an essential step to ensure that the print lasts. Plastisol print requires heat curing to solidify the ink and make it permanently bond to the fabric. The ideal curing temperature for screen printing plastisol ink is around 320°F (160°C). A heat press or conveyor dryer is typically used for this process.

Ensure that the fabric reaches the right temperature for the correct duration to avoid under- or over-curing, which can affect the durability and appearance of your Metallic Gold Screen Printing Ink design. Once cured, the ink will remain flexible and vibrant for the life of the garment.

Enhancing Shine and Durability

One of the key features of Metallic Gold Screen Printing Ink is its incredible shine. To enhance this effect, consider using a clear topcoat or gloss additive to increase the ink’s reflectiveness. This step is particularly useful for prints that need to stand out in low-light environments or when you want to emphasize the metallic finish.

Additionally, proper curing and post-treatment ensure that your prints will withstand multiple washes without losing their luster. Washing your garments inside out and using cold water can help maintain the vibrancy of the Gold Silkscreen Ink for years to come.

Troubleshooting Common Issues

Screen printing with metallic inks can sometimes pose challenges. Here are a few common issues and tips for troubleshooting when using Metallic Gold Screen Printing Ink:

- Ink Bleeding: If the ink bleeds into areas outside the design, it may be due to using too much ink or applying too much pressure with the squeegee. Adjust your technique to prevent ink from spreading beyond the intended area.

- Uneven Prints: If your prints are uneven, this could indicate that the ink wasn’t applied evenly or that the mesh screen is clogged. Regularly clean your screen to avoid ink buildup and ensure smooth, consistent prints.

- Dull Finish: If the metallic ink doesn’t appear as shiny as expected, the curing process might be insufficient. Make sure to follow the recommended curing time and temperature for the best results.

Layering Metallic Gold Ink with Other Colors

One of the creative possibilities with Metallic Gold Screen Printing Ink is layering it with other colors to create unique, multi-dimensional designs. For example, you can layer gold over black ink to create a striking contrast, or pair it with silver for a more sophisticated, shimmering effect. When layering inks, always cure each layer fully before applying the next to prevent smudging or blending of colors.