What is Plastisol Ink?

Conclusion

What is Plastisol Ink? Plastisol ink is a versatile and durable choice for screen printing, offering numerous benefits that make it the industry standard for many applications. Whether you’re printing vibrant T-shirts, creating special effects, or producing long-lasting promotional items, plastisol ink provides the consistency and quality needed for professional results.

While it does have some environmental concerns, there are ways to mitigate its impact through the use of eco-friendly alternatives and sustainable practices. When comparing plastisol ink vs water-based ink, the best choice depends on your specific project requirements, the desired finish, and your commitment to environmental responsibility.

By understanding the properties of What is plastisol ink and how it compares to water-based inks, you can make informed decisions that lead to successful printing outcomes, whether for fashion, promotional products, or creative designs.

What is Plastisol Ink?

What is Plastisol Ink? In the world of screen printing, plastisol ink is a widely recognized and frequently used material. Its popularity stems from its versatility, durability, and ease of use, making it a go-to choice for many printers. But what exactly is plastisol ink, and how does it compare to other types of inks, like water-based inks? This article will explore the characteristics of plastisol ink, how it differs from water-based ink, and which option might be best for your printing needs.

What is Water-Based Ink?

Before diving into plastisol ink, it’s important to understand what water-based ink is and how it functions in the screen printing world. Water-based inks are made primarily from water, pigments, and other natural components, making them a more environmentally friendly option compared to traditional inks.

Characteristics of Water-Based Ink:

- Soft Hand Feel: Water-based inks are absorbed into the fabric rather than sitting on top, resulting in a very soft and breathable finish. This makes them ideal for high-quality garments where comfort is a priority.

- Eco-Friendly: Being primarily water-based, these inks have a lower environmental impact. They contain fewer harmful chemicals and solvents, making them a preferred choice for eco-conscious brands.

- Matte Finish: Water-based inks typically produce a matte finish, which can be more subtle and less shiny than other inks.

- Less Durability: While they offer a softer feel, water-based inks can be less durable than plastisol ink, especially on dark fabrics or after multiple washes.

Water-based inks are often chosen for their eco-friendly properties and the soft, natural feel they impart to garments. However, they require more precise handling during the printing process and longer curing times, which can be a drawback for some printers.

What is Plastisol Ink?

Plastisol ink is a PVC-based ink that has been a cornerstone of the screen printing industry for decades. Unlike water-based inks, plastisol ink does not dry or cure until it is exposed to heat, making it highly manageable during the printing process. This characteristic makes it a favorite among screen printers, especially when working with intricate designs or needing to make adjustments before final curing.

Characteristics of Plastisol Ink:

- Versatility: Plastisol ink can be used on a wide range of fabrics, including cotton, polyester, and blends. It is also compatible with various printing techniques, such as puff printing and high-density printing, adding to its versatility.

- Durability: One of the standout features of plastisol ink is its durability. Once cured, the ink forms a strong bond with the fabric, making it resistant to cracking, peeling, and fading, even after multiple washes.

- Opaque Coverage: Plastisol ink offers excellent opacity, meaning it can cover dark fabrics with bright, vibrant colors without requiring multiple layers of ink.

- Heat Activation: Unlike water-based inks, plastisol ink remains in a workable state until it is exposed to heat, typically through a heat press or conveyor dryer. This allows for easy adjustments during the printing process without the risk of the ink drying prematurely.

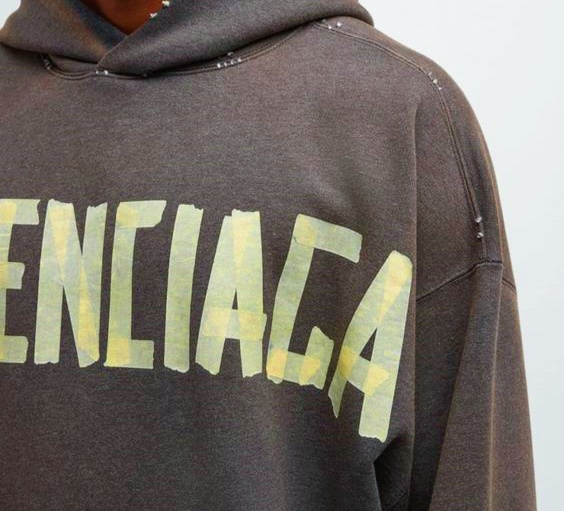

- Thicker Feel: The finish of plastisol ink is thicker and more pronounced on the fabric compared to water-based inks, which can be a desired effect for certain designs.

Plastisol ink is favored for its ease of use, particularly in larger production runs, where consistency and durability are key. Its ability to produce vivid, long-lasting prints has made it the industry standard for many screen printing applications.

Which One is the Best?

When deciding between plastisol ink vs water-based ink, the choice largely depends on the specific requirements of the project and the desired outcome.

Comparing Plastisol Ink vs Water-Based Ink:

- Durability: Plastisol ink is generally more durable than water-based inks. Its ability to withstand multiple washes without fading or cracking makes it ideal for garments that will see heavy use. Water-based inks, while softer, may not hold up as well over time, particularly on dark fabrics.

- Eco-Friendliness: Water-based inks have the edge in terms of environmental impact. They contain fewer harmful chemicals and are easier to clean up, reducing the overall environmental footprint of the printing process. Plastisol ink, on the other hand, contains PVC and other chemicals that require proper disposal and management to minimize environmental harm.

- Hand Feel: For a soft, breathable finish, water-based inks are preferred. They absorb into the fabric, leaving no noticeable texture on the surface. In contrast, plastisol ink creates a thicker, more tactile print, which can be a benefit for certain designs that require a more substantial feel.

- Ease of Use: Plastisol ink is easier to work with, especially for beginners. It remains workable until heat is applied, allowing for corrections and adjustments before curing. Water-based inks, however, can dry quickly on screens, requiring more precise handling and faster printing.

- Application Versatility: Plastisol ink is more versatile when it comes to creating special effects, such as puff prints, high-density prints, and metallic finishes. Its ability to hold shape and remain workable until heat-cured makes it ideal for various creative applications.

Application-Specific Recommendations:

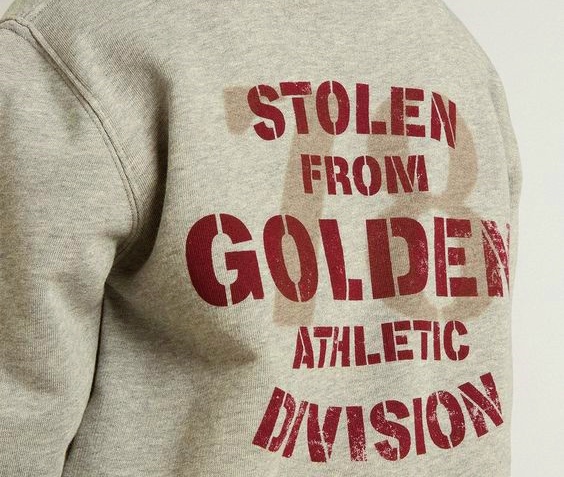

- Fashion Industry: Water-based inks are often preferred for high-end fashion items where a soft hand feel is critical. The ability to create a print that feels like part of the fabric is highly valued in this sector.

- Sportswear and Promotional Items: For sportswear and promotional T-shirts where durability is key, plastisol ink is usually the better choice. Its ability to produce vibrant, long-lasting prints makes it ideal for products that will be worn and washed frequently.

- Creative and Special Effects: Plastisol ink excels in creating special effects, making it a go-to for designers looking to add texture, dimension, or a unique finish to their prints.

Environmental Considerations

While plastisol ink offers numerous advantages in terms of durability and versatility, it is not without its environmental concerns. The PVC content in plastisol ink has been a subject of debate, as PVC production involves harmful chemicals that can be detrimental to the environment if not managed properly.

Reducing Environmental Impact:

- Eco-Friendly Alternatives: Some manufacturers have developed eco-friendly plastisol inks that are phthalate-free and contain lower levels of harmful chemicals. These inks offer a more sustainable option without sacrificing the performance that plastisol ink is known for.

- Proper Disposal: It’s important for screen printers to follow proper disposal protocols for plastisol ink waste to minimize environmental impact. This includes using dedicated disposal facilities and avoiding washing ink residues down the drain.

- Sustainable Printing Practices: Integrating sustainable practices, such as using less ink, reducing waste, and opting for environmentally friendly additives, can help reduce the overall environmental footprint when using plastisol ink.

Special Techniques with Plastisol Ink——Specialty Ink

What is Plastisol Ink? Plastisol ink is particularly valued for its ability to be used in a variety of special techniques that enhance the visual appeal of printed garments.

Puff Printing:

Puff printing is a technique that uses plastisol ink mixed with a puff additive, which causes the ink to expand and create a raised, three-dimensional effect when heated. This technique is popular for adding texture and depth to designs, making them stand out.

High-Density Printing:

High-density printing involves using a thick layer of plastisol ink to create a design with a noticeable raised texture. This method is often used for bold, graphic designs that require a more pronounced visual and tactile impact.

Metallic and Glitter Inks:

What is Plastisol Ink? Plastisol ink can be mixed with metallic or glitter additives to create eye-catching designs with a shiny or sparkling finish. These effects are popular in fashion and promotional items, where a bit of extra flair is desired.

Cleaning and Maintenance

Working with plastisol ink requires careful cleaning and maintenance practices to ensure that equipment remains in good condition and that the printing process runs smoothly.

Cleaning Screens:

Plastisol ink does not dry until it is heat-cured, which makes it relatively easy to clean from screens and equipment. However, it’s important to clean screens promptly after printing to prevent ink buildup, which can clog the mesh and affect future prints.

Solvents and Cleaners:

Specialized solvents and cleaners are available for removing plastisol ink from screens, squeegees, and other equipment. These products are designed to break down the ink without damaging the screens, ensuring a thorough clean.

Routine Maintenance:

Regular maintenance of equipment, such as screens, dryers, and heat presses, is essential when working with plastisol ink. This includes checking for any ink buildup, ensuring even heat distribution in dryers, and maintaining proper tension in screens.