Enhance visibility with reflective silk screen ink. Learn about its benefits, application on t-shirts, durability, and where to buy it.

Table of Contents

How Long Can a Resin Print Stay Uncured Before It Degrades?

Resin prints should not be left uncured for too long, as prolonged exposure to air and UV-sensitive resin can lead to print degradation. Generally, it is best to cure a resin print within a few hours after washing it in isopropyl alcohol or a similar cleaning solution. Leaving a resin print uncured for more than 24 hours increases the risk of warping, tackiness, or contamination. If you’re unable to cure the print immediately, store it in a dark, cool place to prevent unwanted UV exposure.

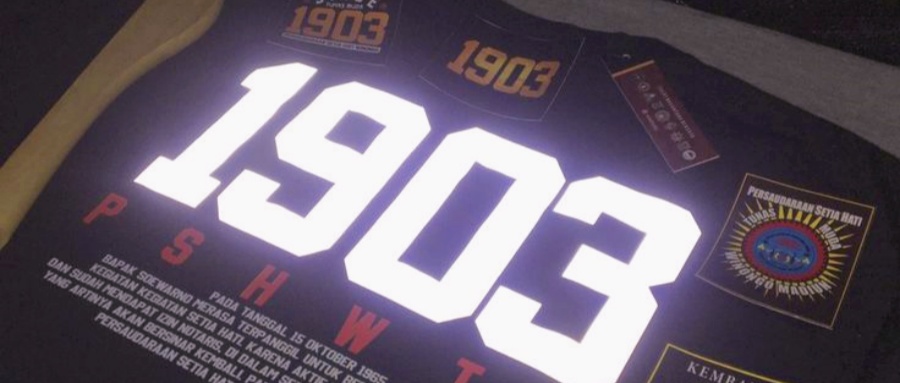

Why Reflective Silk Screen Ink Is a Game-Changer for T-Shirt Printing

Reflective silk screen ink is a game-changer for custom apparel printing, offering enhanced visibility and unique designs. This type of ink contains micro glass beads or other reflective additives that reflect light when illuminated, making it a popular choice for safety apparel, fashion garments, and athletic wear. When using reflective silk screen ink for t-shirts, it’s essential to choose the right ink type and mesh count to achieve optimal results. High-quality inks ensure durability, longevity, and resistance to multiple washes.

The Truth About Reflective Ink: Is It Suitable for Screen Printing?

Yes, reflective ink is available for screen printing. Reflective silk screen ink is specially formulated with light-reflecting elements that create a glowing effect when exposed to light sources such as headlights or flash photography. The ink is commonly used in printing safety gear, high-visibility uniforms, and fashion designs that require a special effect. When choosing reflective silk screen ink, consider factors like ink opacity, curing temperature, and the type of fabric you are printing on.

Revolutionizing Clothing Design with Reflective Printing

Reflective printing on clothing is an innovative method that enhances both aesthetics and functionality. Whether it’s for safety gear, activewear, or fashion-forward designs, reflective silk screen ink plays a crucial role in achieving eye-catching and practical results. The printing process typically involves using plastisol or water-based reflective inks that bond well with fabric and withstand repeated washes. Proper curing is essential to ensure longevity, and using a heat press or conveyor dryer is recommended over a standard hair dryer.

Where to Find the Best Reflective Silk Screen Ink Near You

Finding high-quality reflective silk screen ink near me can be crucial for printers looking to experiment with or expand their offerings. Many suppliers, both online and in physical stores, provide various types of reflective ink suitable for silk screen printing. When searching for reflective ink, consider reputable brands that offer high-opacity formulations, fast curing times, and excellent adhesion to fabrics. Additionally, local print shops and supply stores can be excellent resources for purchasing ink and receiving expert advice on its application.

Plastisol Ink Durability: How Many Washes Can It Withstand?

Plastisol ink is known for its durability, often lasting over 50 washes when properly cured. However, improper curing or excessive washing at high temperatures can reduce its lifespan. To maximize longevity, plastisol ink should be cured at the correct temperature (typically 320°F/160°C) and given ample time to cool before handling. Ensuring proper curing prevents cracking, peeling, or fading, keeping the print vibrant and intact for a long time.

Conclusion

Reflective silk screen ink is an excellent choice for screen printers looking to add a unique, light-reactive effect to their designs. From t-shirts and activewear to safety apparel, this ink type provides an innovative way to enhance visibility and style. When working with reflective silk screen ink, it’s crucial to understand curing techniques, ink durability, and proper washing methods to achieve long-lasting results. Whether you’re looking to source reflective ink near you or understand how it compares to other printing techniques, having the right knowledge ensures success in your printing projects.